There are a lot of sales going on, and I'm interested in a barrel for one of my AR-10 builds. A stainless steel barrel would be better for accuracy but I'm planning to run & gun this particular light-weight AR-10 like an AR-15 and am attracted to the barrel life of a chrome-lined barrel.

Who makes the very best 308 chrome-lined barrels? My priorities are accuracy, first, and weight second. And if all Chrome-lined barrels are not the same, please explain why your suggestion is a cut above the rest.

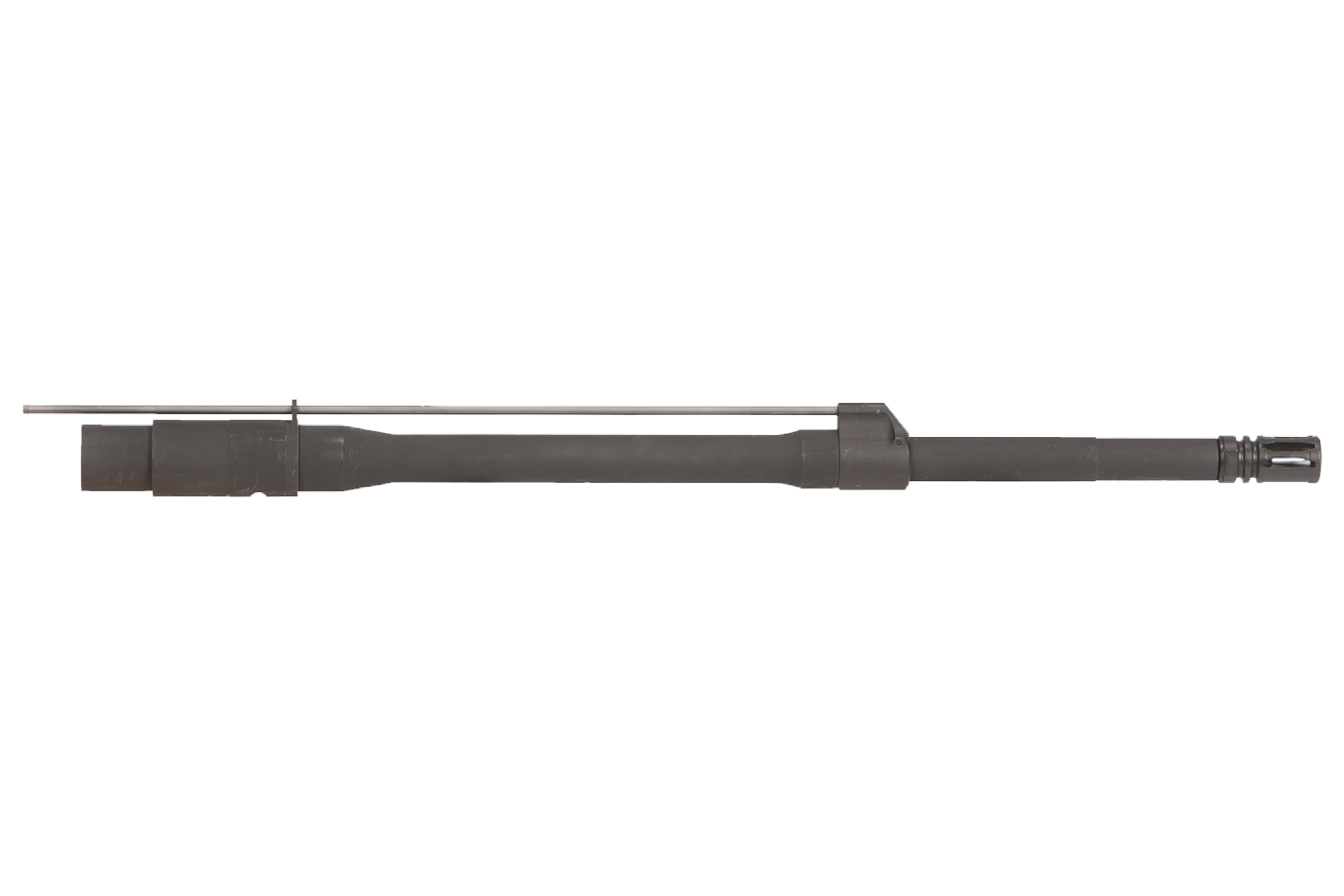

The only one I was thinking about was LMT's 20" chrome-lined barrel. I've heard that Stag, Criterion, and a few other companies make them too, but do any of you have experience with them and can speak on behalf of their accuracy?

Who makes the very best 308 chrome-lined barrels? My priorities are accuracy, first, and weight second. And if all Chrome-lined barrels are not the same, please explain why your suggestion is a cut above the rest.

The only one I was thinking about was LMT's 20" chrome-lined barrel. I've heard that Stag, Criterion, and a few other companies make them too, but do any of you have experience with them and can speak on behalf of their accuracy?