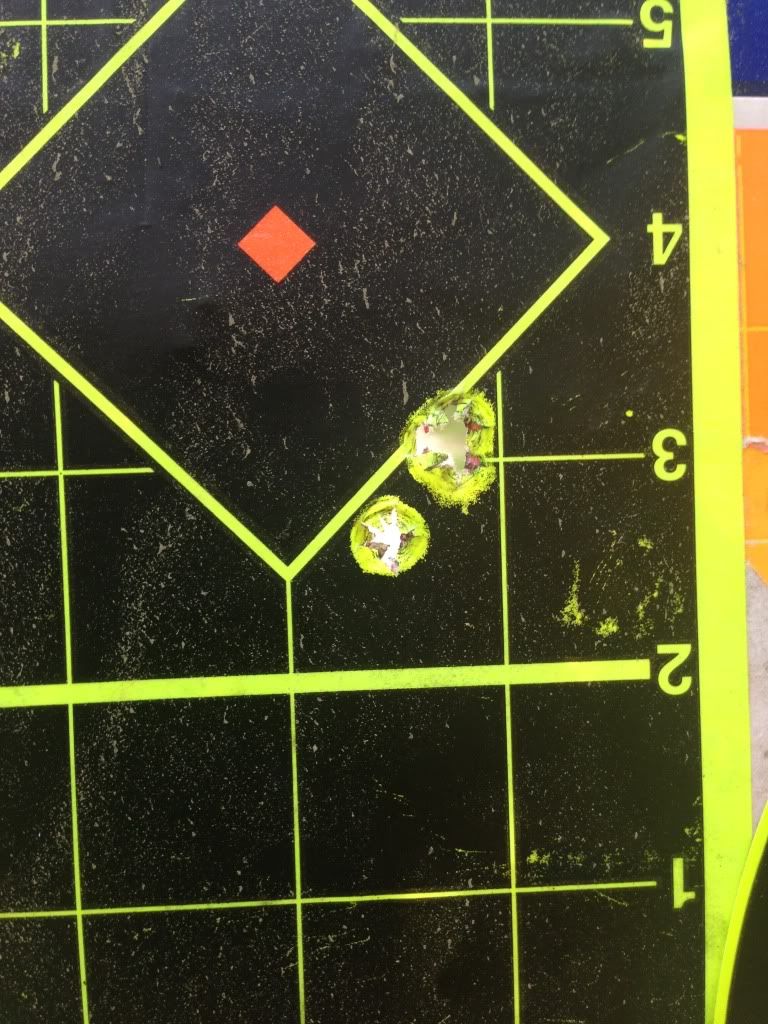

Been annealing myself for a while now but never really asked the guys on here who know their stuff if this looks correct. My method is simple, a butane torch and a drill with a socket adapter. As soon as I see any indicator of "blue" I drop em. They really do add to accurracy and a bit of speed. But for all you guys who know your stuff .. Does this look ok to you??