I'm trying to put together my first rifle build here and I'm having some trouble getting the barrel to sit right. I thought you guys might be able to lead me in the right direction as to how to figure out exactly whats going wrong. Hopefully I can explain this sufficently. I'll try to attach a couple pictures.

What I have is a Defiance Deviant barreled action and a Masterpiece Arms BA chassis.

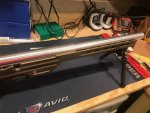

When I torque the action bolts, the barrel cants to the left enough that it just contacts one of the ribs on the chassis. I can't get it to sit concentric in the barrel channel no matter what I do. Hand tight is enough to make this happen.

I machined a fixture thats the same size as a Remington 700 with a barrel on it and this sits perfect. Because of this, I don't think the error is in the chassis.

All that's left I can think of is that either the Deviant action has a machining error or the barrel was threaded crooked. My hunch would be that it's unlikely that the action has an error in it. But, I'm not sure how to tell, or what to do next. Or is this not enough to worry about?

I could machine off the rib where it touches on the chassis to make clearance, but this seems like I'm modifying something thats not wrong in order to accommodate something with an error.

Trying to attach a few pictures that try to show how far off the barrel is in the channel and the fixture I turned sitting true.

What I have is a Defiance Deviant barreled action and a Masterpiece Arms BA chassis.

When I torque the action bolts, the barrel cants to the left enough that it just contacts one of the ribs on the chassis. I can't get it to sit concentric in the barrel channel no matter what I do. Hand tight is enough to make this happen.

I machined a fixture thats the same size as a Remington 700 with a barrel on it and this sits perfect. Because of this, I don't think the error is in the chassis.

All that's left I can think of is that either the Deviant action has a machining error or the barrel was threaded crooked. My hunch would be that it's unlikely that the action has an error in it. But, I'm not sure how to tell, or what to do next. Or is this not enough to worry about?

I could machine off the rib where it touches on the chassis to make clearance, but this seems like I'm modifying something thats not wrong in order to accommodate something with an error.

Trying to attach a few pictures that try to show how far off the barrel is in the channel and the fixture I turned sitting true.