Started loading 223 on the CoAx and quickly found out 2-300 deprimes later I wanted a shorter handle. Not wanting to wait for something to come in the mail it was time to hit the garage.

It would cost about 15$ to make it if you had to buy it all.

Materials

-3/4" round stock

-Pool cue ball

-Jb weld all purpose

Tools

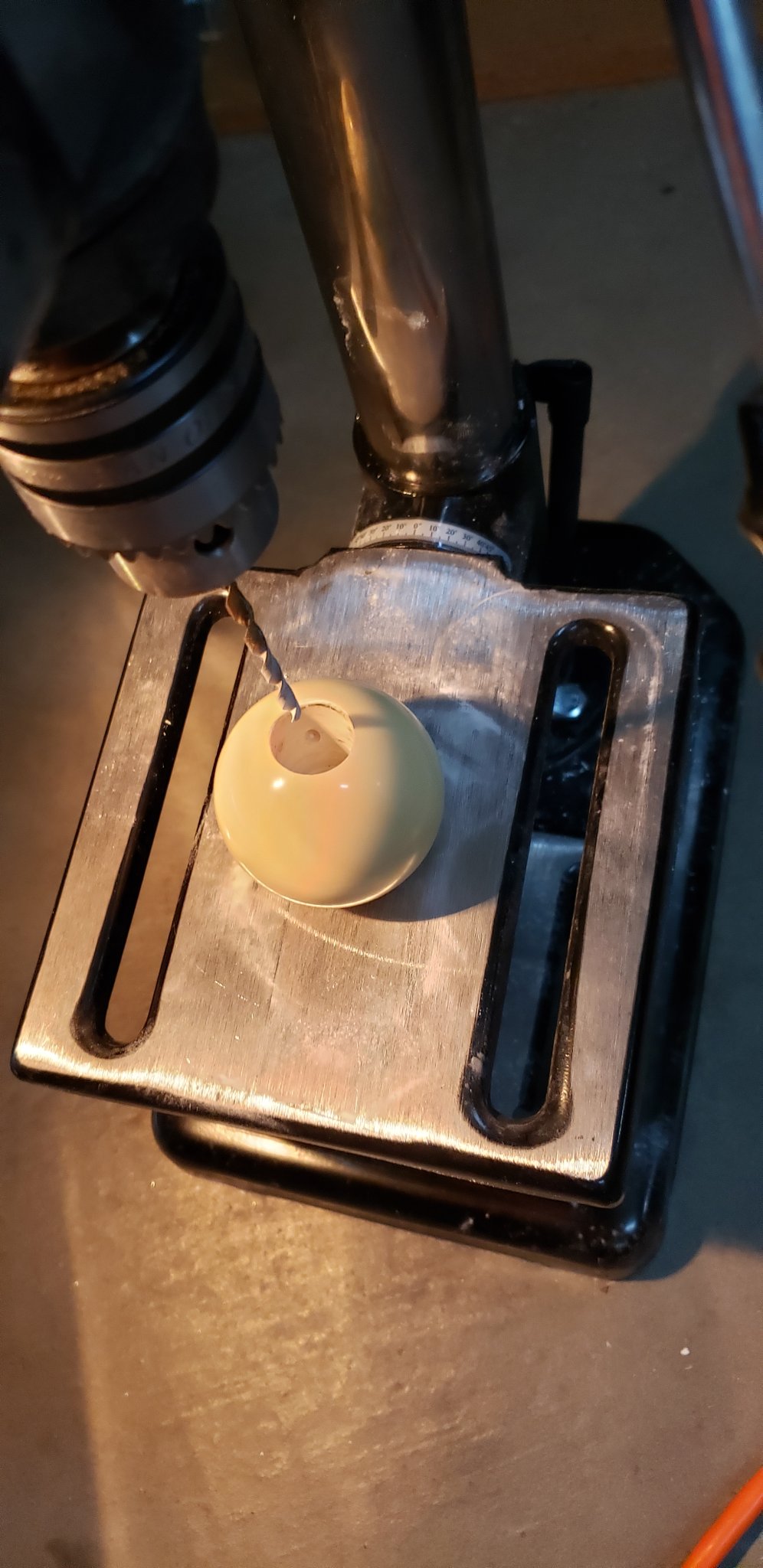

-drill with 3/4" bit

-bi-metal saw blade

-broken pellet grill as paint booth

The copper paint looked way cooler in my head then how it actually turned out. I will probably make another that's black with an 8 ball or 3 ball.

It would cost about 15$ to make it if you had to buy it all.

Materials

-3/4" round stock

-Pool cue ball

-Jb weld all purpose

Tools

-drill with 3/4" bit

-bi-metal saw blade

-broken pellet grill as paint booth

The copper paint looked way cooler in my head then how it actually turned out. I will probably make another that's black with an 8 ball or 3 ball.

Attachments

Last edited: