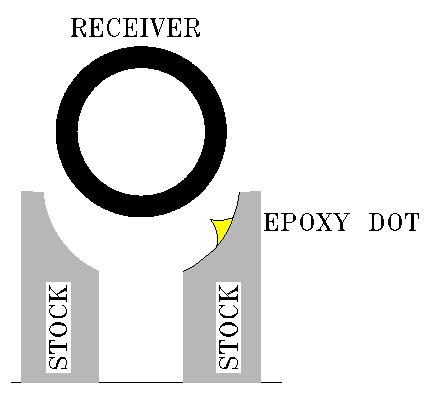

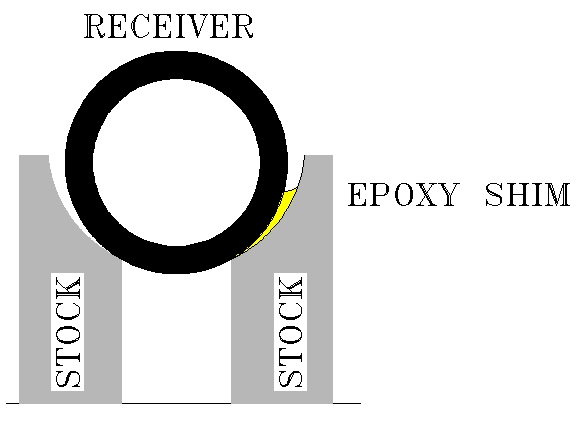

So I decided to pillar bed my CZ 455 Varmint with Thumbhole stock to improve accuracy as much as possible. I wanna use devcon steel for gluing in the pillars and "glas" bedding the action. I found the action can move 2-3mm front to rear. Rifle is in .17 HMR and im getting like 1 MOA groups which is not acceptable for me. So I'm not quite sure what to use for the pillars yet. First option is lamprod M10 thread or aluminium tubing with 1mm wall thinkness. So the problem is the action screw holes are like half open as you can see in the picture. I'm affraid I may ruin the stock because I don't got a drillpress that drills really straigt holes. Will the 1mm aluminium tubing be sturdy enought to withstand the force from tightening the action screws? That way I could just use some sand paper to open up the hole in the stock because the outer diameter of the tube ist just 8mm and the action screw hole is 7mm. Any help would be apreciated. Thanks guys!