The rifle is an Armalite AR-10 chambered for 260 Rem. I run the rifle with a TBAC silencer (hence the dirty brass).

The gas block, handguard and barrel nut had recently been removed for some maintenance work. The 'smith may or may not have gotten the gas block to align correctly with the gas port in the barrel, although he used a bore scope to align the holes.

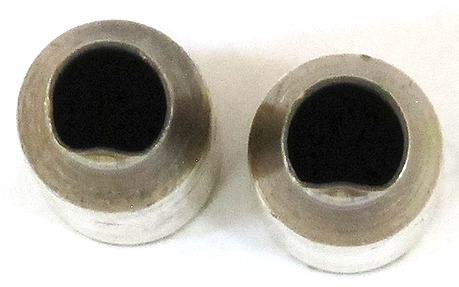

After a PRS match, I noticed that all my cases have a small dent at the mouth. I'm assuming this happens on ejection and wonder if I'm getting insufficient gas flow and the bolt is not going all the way back. Or perhaps it's bouncing due to too much gas. Twice a round started to chamber but the previous case had not ejected completely and was caught sticking out the ejection port. (Annoying while the timer is counting down.) This was new behavior.

I'd just take it to the range and play with the SLR adjustable gas block, but the little adjustment screw head doesn't like any of the SAE or Metric hex wrenches I have and the screw is stuck, so I thought I would tap the knowledge base here while I wait for replacement parts.

Thank you,

Richard

The gas block, handguard and barrel nut had recently been removed for some maintenance work. The 'smith may or may not have gotten the gas block to align correctly with the gas port in the barrel, although he used a bore scope to align the holes.

After a PRS match, I noticed that all my cases have a small dent at the mouth. I'm assuming this happens on ejection and wonder if I'm getting insufficient gas flow and the bolt is not going all the way back. Or perhaps it's bouncing due to too much gas. Twice a round started to chamber but the previous case had not ejected completely and was caught sticking out the ejection port. (Annoying while the timer is counting down.) This was new behavior.

I'd just take it to the range and play with the SLR adjustable gas block, but the little adjustment screw head doesn't like any of the SAE or Metric hex wrenches I have and the screw is stuck, so I thought I would tap the knowledge base here while I wait for replacement parts.

Thank you,

Richard