I keep up with 3 of these rifles so let me explain just a little bit.

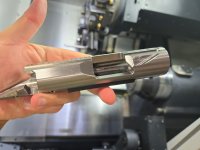

For the bolt that goes with the pics above the pin is out 2 turns with a 15 lb. white spring.

On my bolt the pin is out 2 turns with a 14 lb. red spring.

On the 3rd bolt the pin is out 1 turn with a 14 lb. red spring.

Each bolt is just a little different but set up the way I described they all give the same results.....firing pin strike and on target. I found differences in where the cocking piece indexes when the pin is screwed all the way in and also in the number of turns out it takes for the firing pin to bottom out in the bolt nose.

My headspace is .043/.044 best I can tell.

Hope all this makes sense Sir.

I did the tuning of the firing pin, and I went from 22# spring down to a 15# spring. I never had any failures to fire, but after running a few hundred rounds of ammo, I have found the 22# spring to still have the best SD/ES and group sizes. So I've just left it at 22#.