Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

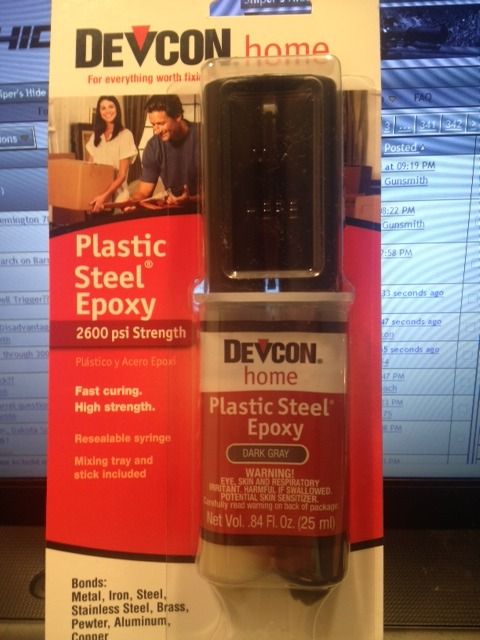

Gunsmithing Devcon Home - Plastic Steel Epoxy? Bedding?

- Thread starter KPK

- Start date

Re: Devcon Home - Plastic Steel Epoxy? Bedding?

Is it steel epoxy or plastic? Either way, it should work fine. Most any epoxy that cures hard will do the job.

Steel putty is nice in that it's very easy to work with, though. Also, that tube looks like barely enough for a full rifle.

Is it steel epoxy or plastic? Either way, it should work fine. Most any epoxy that cures hard will do the job.

Steel putty is nice in that it's very easy to work with, though. Also, that tube looks like barely enough for a full rifle.

Re: Devcon Home - Plastic Steel Epoxy? Bedding?

Be careful with that one. From the pic it looks like a 1:1 mix ratio which, according to the devcon data sheets makes it a 5min epoxy. I've probably bedded over a hundred rifles and I wouldn't be comfortable with a pot life that short.

The 2600psi strength figure doesn't match any product on the data sheets, so I'm not entirely sure I'm looking at the right stuff.

http://www.devcon.com/UserFiles/File/Metals-Putties(1).pdf

second column is what I think it is.

Be careful with that one. From the pic it looks like a 1:1 mix ratio which, according to the devcon data sheets makes it a 5min epoxy. I've probably bedded over a hundred rifles and I wouldn't be comfortable with a pot life that short.

The 2600psi strength figure doesn't match any product on the data sheets, so I'm not entirely sure I'm looking at the right stuff.

http://www.devcon.com/UserFiles/File/Metals-Putties(1).pdf

second column is what I think it is.

Re: Devcon Home - Plastic Steel Epoxy? Bedding?

I've bedded 3 rifles with the mix that you have (1:1) before I realized that it wasn't the same as the tub of devcon. Midway has them listed as the same devcon 10110 at the time I bought it. Either way I didn't have any problems. But after I bought the tub of stuff, they definitely are different. My bedding jobs turned out just fine with what you have.

I've bedded 3 rifles with the mix that you have (1:1) before I realized that it wasn't the same as the tub of devcon. Midway has them listed as the same devcon 10110 at the time I bought it. Either way I didn't have any problems. But after I bought the tub of stuff, they definitely are different. My bedding jobs turned out just fine with what you have.

Re: Devcon Home - Plastic Steel Epoxy? Bedding?

My understanding is that plastic epoxies tend to be more flexible when cured and more easily compressed- as opposed to being rock hard...

You don't want any compression (= movement) when the recoil lug slams back against the epoxy.

My understanding is that plastic epoxies tend to be more flexible when cured and more easily compressed- as opposed to being rock hard...

You don't want any compression (= movement) when the recoil lug slams back against the epoxy.

Re: Devcon Home - Plastic Steel Epoxy? Bedding?

I say give it hell and see how it works. Let us know.

I say give it hell and see how it works. Let us know.

Re: Devcon Home - Plastic Steel Epoxy? Bedding?

I have bedded several rifles and I have never been able to do it in 5 minutes. You could use it to bed a base but with only 5 minutes of set up time I would just use something else if possible. The clean up is always the longest portion of the job.

Rob

I have bedded several rifles and I have never been able to do it in 5 minutes. You could use it to bed a base but with only 5 minutes of set up time I would just use something else if possible. The clean up is always the longest portion of the job.

Rob

Re: Devcon Home - Plastic Steel Epoxy? Bedding?

I dunno...

Temp range for this epoxy is 200-250 degrees.

http://www.itwconsumer.com/userfiles/files/techdata-sheet/DV%20Tech%20Data/62345%20TDS.pdf

Sure seems like a rifle's receiver is gonna get hotter than that near the chamber.

JB Weld is good up to 550 degrees.

http://www.jbweld.com/product/j-b-pro/

Heat is the enemy of epoxies.

I dunno...

Temp range for this epoxy is 200-250 degrees.

http://www.itwconsumer.com/userfiles/files/techdata-sheet/DV%20Tech%20Data/62345%20TDS.pdf

Sure seems like a rifle's receiver is gonna get hotter than that near the chamber.

JB Weld is good up to 550 degrees.

http://www.jbweld.com/product/j-b-pro/

Heat is the enemy of epoxies.

I work with '100% solid' plural component epoxies and urethanes on a regular basis. Most manufacturers claim 100% but in science and real life it is more like 98, 98.5 which is close for hand grenades but bedding compound, eh. This is why a lot of bedding compounds have non non compressable fillers to reduce the amount of actual epoxy for a given volume to reduce shrinkage. Something can be said for uniform bedding thickness to prevent high spots.

To get to the point, once a good coating receipe is developed, manufacturers tend to stick with it until something better comes along or something prohibits its use. The formula is further tweeked to fit specific applications. The stuff it the syringe is probably in the same family as the Devcon 10110 but is difficult to dispense so the smaller component has either had non compressable fillers added to bring to volume up to or an addative to make up the volume so that it could be packaged and dispensed easily. Does this addative cause more shrinking? You need to get a data sheet and msds for each product and compare to be sure. Data sheets can be deceptive by omission where as the MSDS general spells it out unless it is a trade secret.

You will need to use the 10110 as the master and see where the commercially packed steel phtty differs. Warning signs would be additional petroleum solvents which = more shrinkage. Look at the ingredient percentages.

To get to the point, once a good coating receipe is developed, manufacturers tend to stick with it until something better comes along or something prohibits its use. The formula is further tweeked to fit specific applications. The stuff it the syringe is probably in the same family as the Devcon 10110 but is difficult to dispense so the smaller component has either had non compressable fillers added to bring to volume up to or an addative to make up the volume so that it could be packaged and dispensed easily. Does this addative cause more shrinking? You need to get a data sheet and msds for each product and compare to be sure. Data sheets can be deceptive by omission where as the MSDS general spells it out unless it is a trade secret.

You will need to use the 10110 as the master and see where the commercially packed steel phtty differs. Warning signs would be additional petroleum solvents which = more shrinkage. Look at the ingredient percentages.

I have to agree...you will find that the 1:1 ratio product is going to shrink considerably moreI work with '100% solid' plural component epoxies and urethanes on a regular basis. Most manufacturers claim 100% but in science and real life it is more like 98, 98.5 which is close for hand grenades but bedding compound, eh. This is why a lot of bedding compounds have non non compressable fillers to reduce the amount of actual epoxy for a given volume to reduce shrinkage. Something can be said for uniform bedding thickness to prevent high spots.

To get to the point, once a good coating receipe is developed, manufacturers tend to stick with it until something better comes along or something prohibits its use. The formula is further tweeked to fit specific applications. The stuff it the syringe is probably in the same family as the Devcon 10110 but is difficult to dispense so the smaller component has either had non compressable fillers added to bring to volume up to or an addative to make up the volume so that it could be packaged and dispensed easily. Does this addative cause more shrinking? You need to get a data sheet and msds for each product and compare to be sure. Data sheets can be deceptive by omission where as the MSDS general spells it out unless it is a trade secret.

You will need to use the 10110 as the master and see where the commercially packed steel phtty differs. Warning signs would be additional petroleum solvents which = more shrinkage. Look at the ingredient percentages.

Similar threads

- Replies

- 8

- Views

- 336

- Replies

- 5

- Views

- 209