I've read that the xmark triggers are inconsistent on the internet so it must be true. Plus with the remington recall...just get it done cause I sure as hell ain't sending it to them

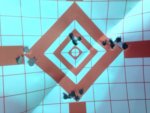

I guess I need to start understanding parallax.

i have the xmark gen 1 in mine, 1.5lbs consistantly measured on a basic wheeler gauge and a digital one. just spent time adjusting the screws once the glue was removed, and doused it with break free. no creep, just a plain jane factory trigger - no accidental discharges yet.

originally was going to replace it or put a spring kit in it, figured it shoots sub moa out to 425 (my longest local range) so i can put the 100.00 - 200.00 toward reloading components instead. perhaps mine is the one in a million, but i'm not planning on replacing it, as there is no need to.

Parallax in Rifle Scopes

What exactly is parallax anyway? - The Optics Talk Forums

there was a great post on parallax here somewhere, i think it was by LL himself, but i can't seem to locate it.

as mentioned before, trigger squeeze directly rearward, cheek weld, gripping pressure, follow through, breathing, making sure your shouldering it the same, not flinching - all done properly can produce good results with the worst of triggers installed.

i think it's your cheek weld / eye alignment with the optic. equipment seems to be good, it just small rough edges in form that can be corrected. i've found for me "kissing" the stock in the same manner just like using a kisser button on archery equipment has really got me more consistant.

try 5 white pages, 5 1" spots 1 shot per page. scope on 10 or 12X. concentrate on trigger squeeze directly rearward, cheek weld, gripping pressure, follow through, breathing, not flinching.

or just 5 blank printer papers, no spots, aim center on the first round, then try to hit that hole with the next 5 on each paper.

stack the papers at the end of session, betchya see most of the hits clover leafing within 1" of each other.