Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rifle Scopes Do you lube your 1913 rail?

- Thread starter JWG

- Start date

No, because using lubricant to increase friction is stupid.

Dude seems to be new to the site.

Sure his question may seem dumb but at least he asked it.

Perhaps he is thinking of issues of corrosion or something when whatever is attached to the rail needs to be removed.

Go easy on the boot.

No OP you need not lube the rail.

Whatever you attach to it push it forward as you tighten to ensure the recoil lug is seated against a rail lug and tourge the item to manufacturers spec.

EDIT - My bad.....been here two years. Maybe he doesnt read a lot.

Sure his question may seem dumb but at least he asked it.

Perhaps he is thinking of issues of corrosion or something when whatever is attached to the rail needs to be removed.

Go easy on the boot.

No OP you need not lube the rail.

Whatever you attach to it push it forward as you tighten to ensure the recoil lug is seated against a rail lug and tourge the item to manufacturers spec.

EDIT - My bad.....been here two years. Maybe he doesnt read a lot.

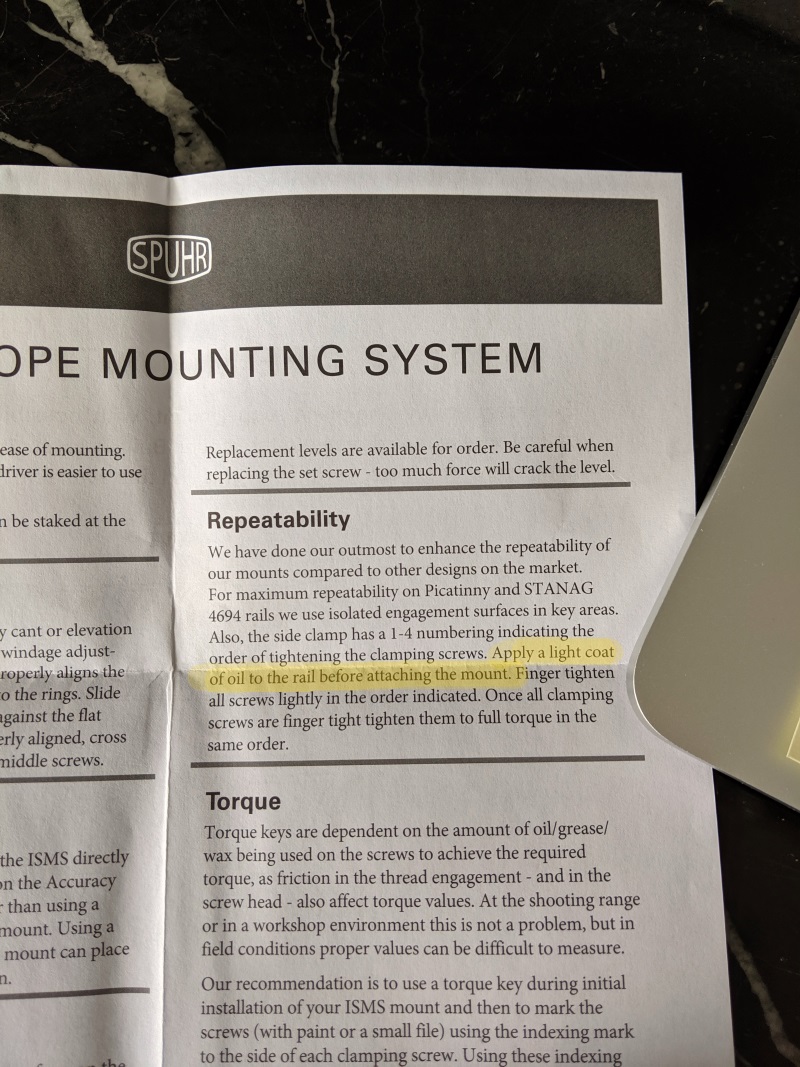

Hakan Spuhr told me to. Inquestioned him further and he reiterated this even providing a photo so language barrier wasnt a possiblity.Seriously, who put this idea in your mind?

Last edited:

That makes no sense. Oil on the rail would be a dirt magnet and how does a lubricant prevent the mount from moving around?

Is this a joke?

Is this a joke?

One has to assume that Facebook post was written on April 1?

Hakan Spuhr told me to. Inquestioned him further and he reiterated this even providing a photo so language barrier wasnt a possiblity.

I don't care if God himself told you to. It's bullshit. Or a joke and you're the butt of it.

Common sense and over 30 years of mechanical engineering expertise tell me so.

my buddy asked about this also...this was the explanation he was given basically...its not to increase friction, its to aid alignment

idk if its true or not, dont care and havent tested it...when im mounting rings i usually carefully align the rings and the clamp pieces while torquing anyways so i dont really worry about them binding

idk if its true or not, dont care and havent tested it...when im mounting rings i usually carefully align the rings and the clamp pieces while torquing anyways so i dont really worry about them binding

????

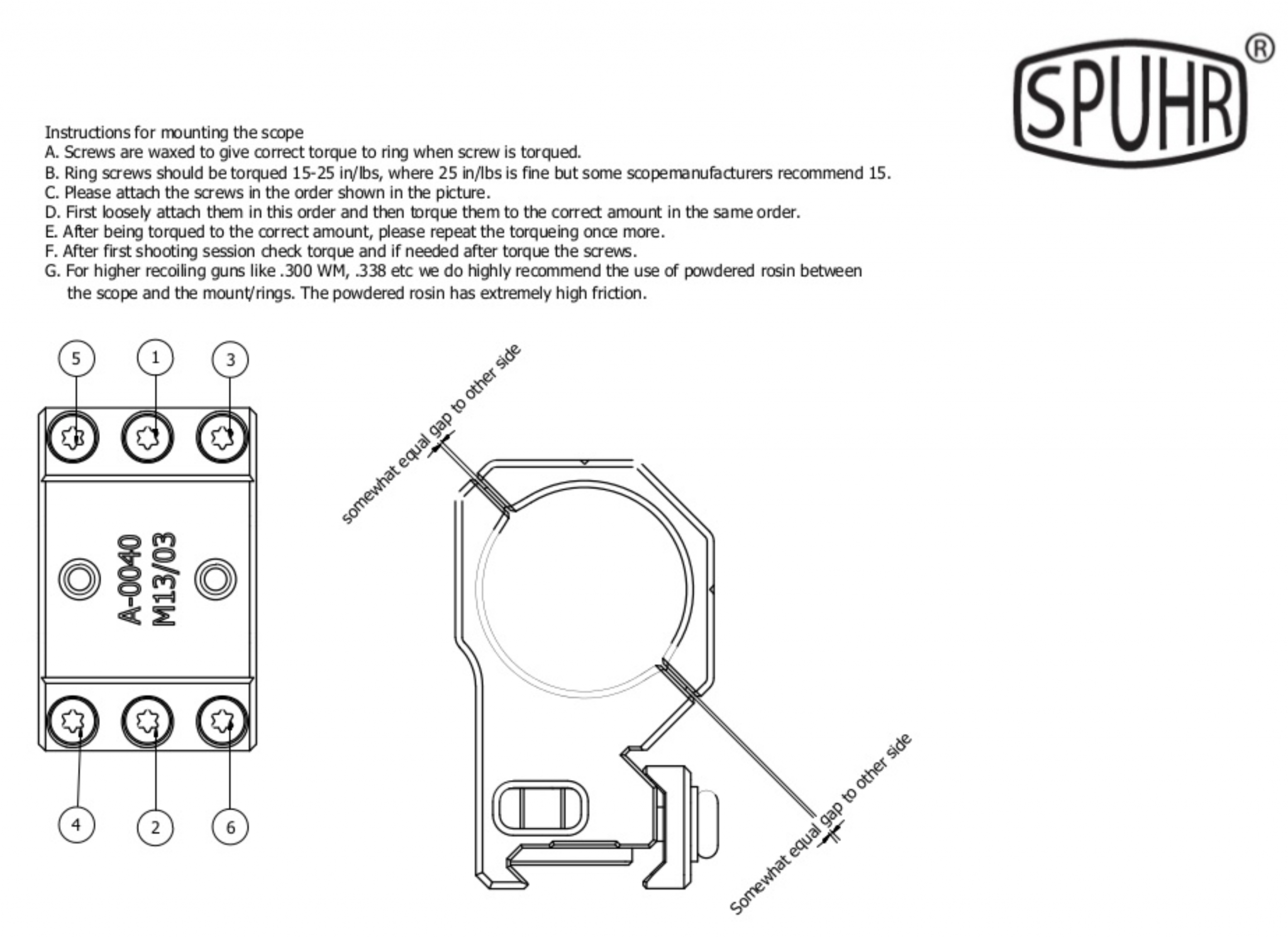

The fairly few instructions I can even find from Spuhr like this make no mention.

My rails may incidentally have a light coating of some oil as the outside of my guns is generally not totally degreased, but I also have never heard of specifically oiling pic rails, weaver rails, etc. Ever.

The fairly few instructions I can even find from Spuhr like this make no mention.

My rails may incidentally have a light coating of some oil as the outside of my guns is generally not totally degreased, but I also have never heard of specifically oiling pic rails, weaver rails, etc. Ever.

possibly the coating of oil on the rail scope interface limits the effect of surface imperfections (dirt, rough ceracote, spray painting etc) on clamping force.

it may allow the clamps to "slip by" and have the clamping force on more stable material, not just on a "peak thats grabby"

protection?:

possible rust issues with poor surface protection on action or rail

different materials will weld/rust themselves together over time. rail and mount are not "friends"

??

it may allow the clamps to "slip by" and have the clamping force on more stable material, not just on a "peak thats grabby"

protection?:

possible rust issues with poor surface protection on action or rail

different materials will weld/rust themselves together over time. rail and mount are not "friends"

??

Nopepossibly the coating of oil on the rail scope interface limits the effect of surface imperfections (dirt, rough ceracote, spray painting etc) on clamping force.

it may allow the clamps to "slip by" and have the clamping force on more stable material, not just on a "peak thats grabby"

Uh, generally if anything is added it's a thin layer of blue loctite, not oil!

Maybe I am missing something but how in hell is this actually a discussion??

Absolutely NO reason for oil on the rail.

Absolutely NO reason for oil on the rail.

'Cause Hakan Spuhr...silly!Maybe I am missing something but how in hell is this actually a discussion??

Absolutely NO reason for oil on the rail.

If John Browning told you to only clean and service the Government Model pistol loaded would that make it wise?

I have found that hitting the scope with a hammer is a much more "real world" test than to merely hit your scope with an "open hand". What kind of pussy hits their $3000 scope with an open hand?

Touché good sirWhat if it's an Anschutz 1913?

What if it's an Anschutz 1913?

HA!!Touché good sir

'Cause Hakan Spuhr...silly!

You know your right, WTF am I thinking. I should know never to think for myself. Ill get back in the flock and follow mindlessly...

I’ll go against the grain and agree with spuhr.

I actually do add lube on all mating surfaces between my rings and scope rail and have been for some time now.

There is a reason.

If something seems stupid but it works.... it’s not stupid.

Here’s my .02, If what you’re doing already works, don’t change it.

Pretty simple.

I actually do add lube on all mating surfaces between my rings and scope rail and have been for some time now.

There is a reason.

If something seems stupid but it works.... it’s not stupid.

Here’s my .02, If what you’re doing already works, don’t change it.

Pretty simple.

Last edited:

I’ve had the same conversation with Hakan regarding his testing. He first mentioned it to me 2-3 SHOT show’s ago? (only time I see him). I do lube then wipe down parts when mounting bases & rings to base now.

I can see oiling a steel rail for corrosion resistance. But what other practical purpose could it possibly serve? From the physics standpoint, how does adding lubricant to a mating surface make a metal part LESS likely to slide? Think of a semi-auto pistol: you lubricate the slide/frame mating interface (rails) to reduce friction and aid the slide’s movement, not to impede it.I’ll go against the grain and agree with spuhr.

I actually do add lube on all mating surfaces between my rings and scope rail and have been for some time now.

There is a reason.

If something seems stupid but it works.... it’s not stupid.

Here’s my .02, If what you’re doing already works, don’t change it.

Pretty simple.

How do you know that lubing your rail “works”? How do you measure the improvement?

I can see oiling a steel rail for corrosion resistance. But what other practical purpose could it possibly serve? From the physics standpoint, how does adding lubricant to a mating surface make a metal part LESS likely to slide? Think of a semi-auto pistol: you lubricate the slide/frame mating interface (rails) to reduce friction and aid the slide’s movement, not to impede it.

How do you know that lubing your rail “works”? How do you measure the improvement?

+1 I will be the first to admit I am wrong if someone can either prove to me the benefit from a retention (better clamping force, less chance of slippage) standpoint, or explain the reason why with logic as opposed to "just because it does". I do not mean to come across like a know it all or an expert, but I have a lot of first hand experience in this area as a high end specialty mechanic with almost 20 years in the field. Bolting things together so they stay put is critical to my job. I have been to countless commercial and private schools from the very basic to the most cutting edge with world leading companies and this has never come up, there are applications where you use a friction or adhesive compound for better retention but never a lubricant such as oil. I completely understand a light lube on the fasteners to reduce friction and galling which can increase clamping force but that is based on the actual rotational torque applied to the driver of the fastener (kinda of a different thing).

I have become pretty interested in this and as time allows (maybe this weekend I am going to research it). But if anyone can point me in the direction of some studies I would be greatly appreciated. If it proves to be true I WILL talk shit about myself and take back what I have said, until then I firmly stand behind my thoughts.

First is defining the problem.

The problem is not necessarily a lack of clamping force. The issue is when optic/mount is impacted (Force of an open palm hand is enough as Spuhr tested) it can move enough where the original mount alignment is slightly off due to friction points between the mount. Rails and mounts are designed to work together but they are not perfectly matched.

Increasing clamping Force is not the intention of the lubrication. The goal is to allow the mating surfaces to “free float” to some degree so it will not stick and return closer to its orientation when the optic was zeroed.

Even still adding lube doesn’t “fix” the problem but it helps.

Similar to why ARC made a recommendation for adding anti seize to the mating surfaces on the barloc. They didn’t say it would fix it, but it may help.

Again.... I’m not going as far to say every mount has this issue. Your rail to mount interface may be better than mine. Spuhr has apparently done some extensive testing and has made the recommendation using their mounts.

Now if you’re like me, I don’t particularly make it a habit to go out and smack my barrels and optics for the hell of it, so hopefully I’ll never have a problem when it really counts.

I also know that adding lube has never created a problem of losing my zero shot to shot. Ever.

I’m not a mechanical engineer, I’m just a shooter. So if the physics and science say otherwise I am also happy to admit that I’m wrong as well.

That being said I still will continue to use lube because it has improved my return to zero when taking off my optics from my rails and I’m not as concerned about the potential for poi shift if my optic gets bumped, nor has it had any negative impact on holding zero shot to shot. It may not fix it, but it helps.

The problem is not necessarily a lack of clamping force. The issue is when optic/mount is impacted (Force of an open palm hand is enough as Spuhr tested) it can move enough where the original mount alignment is slightly off due to friction points between the mount. Rails and mounts are designed to work together but they are not perfectly matched.

Increasing clamping Force is not the intention of the lubrication. The goal is to allow the mating surfaces to “free float” to some degree so it will not stick and return closer to its orientation when the optic was zeroed.

Even still adding lube doesn’t “fix” the problem but it helps.

Similar to why ARC made a recommendation for adding anti seize to the mating surfaces on the barloc. They didn’t say it would fix it, but it may help.

Again.... I’m not going as far to say every mount has this issue. Your rail to mount interface may be better than mine. Spuhr has apparently done some extensive testing and has made the recommendation using their mounts.

Now if you’re like me, I don’t particularly make it a habit to go out and smack my barrels and optics for the hell of it, so hopefully I’ll never have a problem when it really counts.

I also know that adding lube has never created a problem of losing my zero shot to shot. Ever.

I’m not a mechanical engineer, I’m just a shooter. So if the physics and science say otherwise I am also happy to admit that I’m wrong as well.

That being said I still will continue to use lube because it has improved my return to zero when taking off my optics from my rails and I’m not as concerned about the potential for poi shift if my optic gets bumped, nor has it had any negative impact on holding zero shot to shot. It may not fix it, but it helps.

Last edited:

I’ll go against the grain and agree with spuhr.

I actually do add lube on all mating surfaces between my rings and scope rail and have been for some time now.

There is a reason.

If something seems stupid but it works.... it’s not stupid.

Here’s my .02, If what you’re doing already works, don’t change it.

Pretty simple.

If that’s the reason I don’t buy it. If it’s some other secret reason do tell.

It doesn’t make sense. If the parts don’t mate adding oil will do nothing. The peaks and valleys will have a coating of oil but in no way will that “even out” the metal. All you’re doing is reducing the friction where the metal does mate. This cannot possibly create a more stable or solid mount.

Either this is retarded or I’m retarded.

Apparently rubbing a bar of soap on a muscle cramp relieves it. No one seems to know why it works, but it does. Maybe this works, but if it does it’s not because it changes the structure of the metal or acts like floor leveler.

Exactly. it's like trying to fix potholes on the road by filling them with water.If that’s the reason I don’t buy it. If it’s some other secret reason do tell.

It doesn’t make sense. If the parts don’t mate adding oil will do nothing. The peaks and valleys will have a coating of oil but in no way will that “even out” the metal. All you’re doing is reducing the friction where the metal does mate. This cannot possibly create a more stable or solid mount.

Exactly. it's like trying to fix potholes on the road by filling them with water.

Missing the point of the lubrication. It isn’t supposed to act like a filler or leveler to improve the mating surfaces...nor is it supposed to increase friction or stability.

I'm not saying it's supposed to act as filler or increase friction - that's the opposite of what I'm saying. Lubrication decreases friction, which is the opposite of what you want when the goal is to have the part stay in place and not move.Missing the point of the lubrication. It isn’t supposed to act like a filler or leveler to improve the mating surfaces...nor is it supposed to increase friction or stability.

I'm not saying it's supposed to act as filler or increase friction - that's the opposite of what I'm saying. Lubrication decreases friction, which is the opposite of what you want when the goal is to have the part stay in place and not move.

Zero science behind my interpretation. But the way I’m understanding is, regardless, the mount is going to move some when enough force is applied.

It’s then going to try to return to the clamped position. The oil allows it to move back easier. Without the oil, it may only snap back partially.

I’d imagine we are talking extremely small measurements.

And again, no science to back up my understanding and I’m not sure if I agree or disagree with it because I’m not educated enough on the physics of it.

I have a 50 gallon drum of 5-W30 motor oil and after cleaning all my weapons, I like to give them a good long soak in the oil, then let them just hang drip/dry for a week.

Good to go.

Good to go.

The oil recommendation is in the "Repeatability" section of the instructions, which should be a clue as to the reason for it: The lubrication helps to prevent the mount from sticking as it's being tightened on the rail, so it can freely slide into the same position if it's removed and replaced.

I wonder just how terribly bad this would go if it was a dovetail mount instead? I've sheared my fair share of recoil pins off of them before, and they were perfectly torqued and dry.

I understand what you’re getting at but the thing is it’s not the solution to the problem.

If it was such a big deal (optics moving and your zero shifting from bumps) then the solution wouldn’t be to add a lubricant so the mount it can return back to it’s original position (or closer to its original position than without it) it would be to size the wedge so there’s no physical movement possible front to rear on the picatinny rail when it’s clamped down, which has been done before and since its inception hasn’t become to industry standard or norm or even been widely praised as the solution to every body’s optics moving (even though it does solve that problem).

So since it hasn’t taken off I’m going to go out on a limb and say it’s not enough of a problem to bother lubing your rail to avoid it because if it was such a big deal, the solution below exists and you’d just buy one of these if you were actually really concern about it and constantly had that problem.

So lubing the rail is garbage as far as I’m concerned.

Again...... never said it was the solution.

Also said if you don’t have a problem don’t worry about it.

I’ll keep doing what I’m doing.

Spuhr will continue to recommend what they recommend.

No hard feelings here. It really doesn’t matter to me whether or not I convince anyone. Calling it garbage is fine. There are countless others who have way more education in these matters that also agree it doesn’t hold water.

It’s not my concept, so I don’t take it personal. I learned it from someone else and have been doing it ever since. It works for me, and I have yet to see any negative effects on target.

You can't prove that it works.I’ll go against the grain and agree with spuhr.

I actually do add lube on all mating surfaces between my rings and scope rail and have been for some time now.

There is a reason.

If something seems stupid but it works.... it’s not stupid.

Here’s my .02, If what you’re doing already works, don’t change it.

Pretty simple.

Similar threads

- Replies

- 2

- Views

- 248

- Replies

- 22

- Views

- 1K

- Replies

- 0

- Views

- 309