Re: First chamber job

Sorry, realized this was a pretty limited post information wise. The barrel is a Rock (will finish at 26"), 1:10 twist. I used the .308 Bisley reamer from PTG. I am planning on shooting the 208 HPBT bullets from Hornady through it, not sure if I will have to throat it out yet or not. A machinist or gunsmith I am not. I plan to eventually branch out and do some local smithing, but I am not ready for that yet. More of a hobbiest right now.

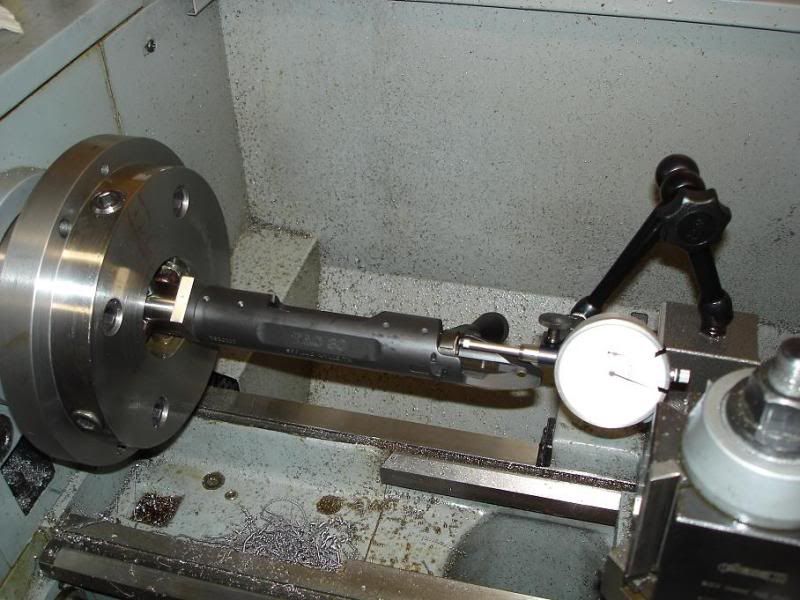

As to the hardest/scariest part, I guess for me the hardest was dialing in the chamber length of the bore to zero runout. I had to use an extension to reach my rear spindle spider, so there was more flex in the tubing than in the barrel itself. I wasn't happy with it all the way because it wasn't dead perfect. At the throat I was less than .0001", but at the end of the breech it wasn't quite that good, it was still just under .0005", but I thought it should be better. Anyway, I pre-bored that section out conentric before running the reamer in, so it won't make a difference, I was just frustrated that I wasn't able to get it nuts all the way out. The scariest part for me was the last few thou of the chamber... at that point everything else is nuts, so you sure don't want to drive it in deep and have to re-touch the shoulder, face, and bolt recess again...