*** Special thanks to hide member reubenski who's setup with barrel flats inspired this rabbit hole. ***

The last couple of years I've moved to a modular rifle system that uses Bighorn actions and a pile of interchangeable barrels in various chamberings and states of wear. The weak link in all of this was always the time and equipment required to swap the barrels around. Thinking about this led me to develop a system (based around a barrel vise) for quickly changing rifle barrels in the field (or at home). It came out better than I thought, and I had a batch of them made (instead of just one) because I'm certain other shooters would like the capacity it offers.

Here's a quick demo video:

To lay it out in more detail:

In order to remove or install a barrel using this method, you need to get a grip on the barrel and on the action or stock.

GRIPPING THE BARREL

This is what the Ross Vise is designed to do.

INSTALL THE VISE

Loosen the cap nuts, then slip the vise around your barrel with the square drive recesses facing the muzzle. Hand tighten the cap nuts.

TORQUE THE CAP NUTS

Tighten the nuts using a torque wrench, ratchet, or breaker bar with a 15/16 socket (a deep socket will work best), a 15/16 end wrench, or an adjustable wrench. If using a torque wrench, torquing the cap nuts to the same spec as the barrel is tightened to has always proved sufficient to remove it without slippage. The stock or chassis makes for great leverage so it is easy to get the nuts tight, we recommend you turn the rifle vertically. Avoid using the scope or scope rings for leverage.

TORQUE THE BARREL

Insert a torque wrench, ratchet, or breaker bar into one of the 1/2" square drive recesses on the face of the vise. If you desire to protect the finish of your vise, we recommend using a 3/8" drive with a 1/2" adapter, or a short 1/2" drive extension, in order to keep the wrench clear of the vise. The vise is made of anodized aluminum, and while it is durable, it will show marks if you repeatedly hit it with steel!

GRIPPING THE ACTION / STOCK

Now that we have plenty of leverage on the barrel, we need leverage on the action. Exactly how we get this will depend upon how tight your barrel is installed, what type of stock or chassis you have, and what you are comfortable with. Here's a few options:

GRIP THE STOCK - AND POP THE BARREL LOOSE

If you run a light torque value on your barrels, it is possible to remove and install the barrel using only the leverage afforded by the stock. In testing we have found 30 ft-lb to be easy to reach, and 40 ft-lb to be within reach - though no longer "easy". The exact technique used matters, place your foot at the butt of the rifle and put the grip into your calf. Many competitive shooters run torque values this light on their barrels with great success. The biggest downside that we see with running a lightly torqued barrel is you are a little bit closer to having your barrel come loose. If your barrel becomes loose during a competition or a hunt, your ability to hit your target will be compromised, severely!

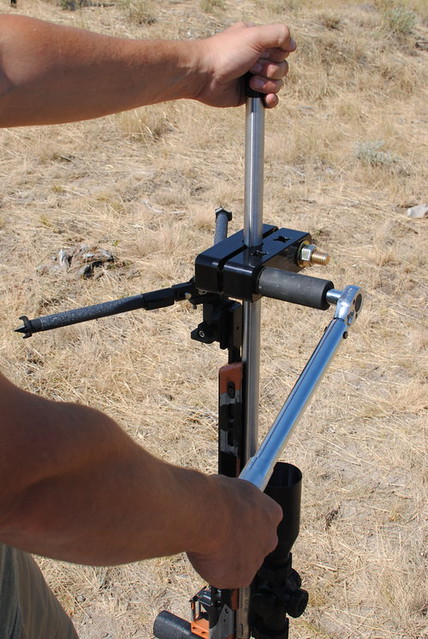

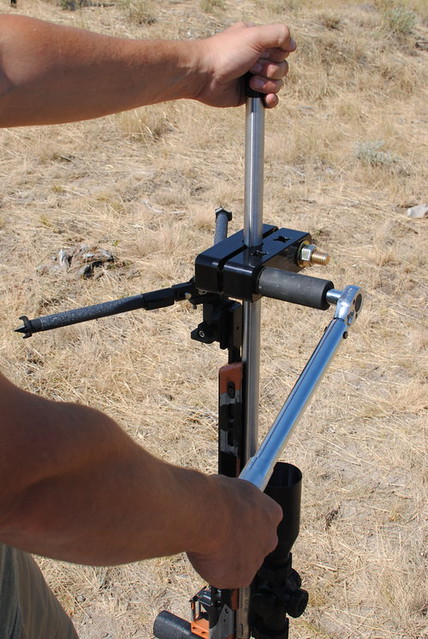

INSIDE ACTION WRENCH AND A T-HANDLE

By using an action wrench with a T-handle in combination with the vise, you are essentially exerting the same forces on your barrel and action as you would installing and removing barrels the traditional way, in a shop, with a bench mounted vise and an inside action wrench. By using a strap around the T-handle, you will keep the assembly from falling out of the rifle and save yourself a lot of frustration. This method will easily support the 80 ft-lb torque that is the recommended maximum for the vise, if you desire your barrels to be that tight. The only downsides to this method are that it requires you to own an inside action wrench for your action(s), and that it can be a little slower to set up, especially if you have an adjustable cheek piece in the way which must first be removed.

PIPE CLAMP

Using an inexpensive iron pipe clamp (my clamp came from Harbor Freight for ~ $10, and my 3/4" pipe came from the hardware store for less than that), tighten the clamp around your chassis or stock, and use the pipe as the leverage to remove and install your barrel. Add some rubber to the jaws (another $2 at the hardware store) to avoid damage to your stock or chassis. We recommend clamping around the recoil lug/front action screw juncture, and proceeding with caution! When using this method you are transferring force from the clamp to the stock - and then from the stock to the action via the action screws and any bedding surrounding the recoil lug. We have had great success with this method and have not damaged anything, but the potential is there. Be especially cautious about using this method with a lightly built wood, fiberglass, or carbon fiber stock. In our testing we used this method on a bedded rifle in a chassis - and after 100 removals and installs at 80 ft-lb the bedding was still tight and showed no signs of being worse for the wear, nor did any other components.

"MPA ROD"

For those with the popular Masterpiece Arms chassis, there is a recess behind the grip that will ALMOST take a 1 1/2" x 1/2" piece of aluminum stock (as seen in the demo video at the top of the page). I purchased a 2 foot piece that size from the local metal supply for ~ $10, and then spend about 10 minutes with a flap disc on an angle grinder rounding off the edges and taking the last two inches down from .500" to .475" so it would slip into this recess. As with the pipe clamp method, you are transferring force through your action screws and bedding, so proceed with caution. For testing purposes, I installed and removed a barrel set to 120 ft-lbs using this method with no ill effects, however I absolutely do not recommend that much torque, nor do I take responsibility if you manage to damage your stock using this technique. Additionally, if you are particular about the finish on your chassis inside this pocket, this will scratch it slightly, so proceed with that knowledge

If you're interested, there's even more detail at the site I set up: www.rossprecisionmt.com.

The last couple of years I've moved to a modular rifle system that uses Bighorn actions and a pile of interchangeable barrels in various chamberings and states of wear. The weak link in all of this was always the time and equipment required to swap the barrels around. Thinking about this led me to develop a system (based around a barrel vise) for quickly changing rifle barrels in the field (or at home). It came out better than I thought, and I had a batch of them made (instead of just one) because I'm certain other shooters would like the capacity it offers.

Here's a quick demo video:

To lay it out in more detail:

In order to remove or install a barrel using this method, you need to get a grip on the barrel and on the action or stock.

GRIPPING THE BARREL

This is what the Ross Vise is designed to do.

INSTALL THE VISE

Loosen the cap nuts, then slip the vise around your barrel with the square drive recesses facing the muzzle. Hand tighten the cap nuts.

TORQUE THE CAP NUTS

Tighten the nuts using a torque wrench, ratchet, or breaker bar with a 15/16 socket (a deep socket will work best), a 15/16 end wrench, or an adjustable wrench. If using a torque wrench, torquing the cap nuts to the same spec as the barrel is tightened to has always proved sufficient to remove it without slippage. The stock or chassis makes for great leverage so it is easy to get the nuts tight, we recommend you turn the rifle vertically. Avoid using the scope or scope rings for leverage.

TORQUE THE BARREL

Insert a torque wrench, ratchet, or breaker bar into one of the 1/2" square drive recesses on the face of the vise. If you desire to protect the finish of your vise, we recommend using a 3/8" drive with a 1/2" adapter, or a short 1/2" drive extension, in order to keep the wrench clear of the vise. The vise is made of anodized aluminum, and while it is durable, it will show marks if you repeatedly hit it with steel!

GRIPPING THE ACTION / STOCK

Now that we have plenty of leverage on the barrel, we need leverage on the action. Exactly how we get this will depend upon how tight your barrel is installed, what type of stock or chassis you have, and what you are comfortable with. Here's a few options:

GRIP THE STOCK - AND POP THE BARREL LOOSE

If you run a light torque value on your barrels, it is possible to remove and install the barrel using only the leverage afforded by the stock. In testing we have found 30 ft-lb to be easy to reach, and 40 ft-lb to be within reach - though no longer "easy". The exact technique used matters, place your foot at the butt of the rifle and put the grip into your calf. Many competitive shooters run torque values this light on their barrels with great success. The biggest downside that we see with running a lightly torqued barrel is you are a little bit closer to having your barrel come loose. If your barrel becomes loose during a competition or a hunt, your ability to hit your target will be compromised, severely!

INSIDE ACTION WRENCH AND A T-HANDLE

By using an action wrench with a T-handle in combination with the vise, you are essentially exerting the same forces on your barrel and action as you would installing and removing barrels the traditional way, in a shop, with a bench mounted vise and an inside action wrench. By using a strap around the T-handle, you will keep the assembly from falling out of the rifle and save yourself a lot of frustration. This method will easily support the 80 ft-lb torque that is the recommended maximum for the vise, if you desire your barrels to be that tight. The only downsides to this method are that it requires you to own an inside action wrench for your action(s), and that it can be a little slower to set up, especially if you have an adjustable cheek piece in the way which must first be removed.

PIPE CLAMP

Using an inexpensive iron pipe clamp (my clamp came from Harbor Freight for ~ $10, and my 3/4" pipe came from the hardware store for less than that), tighten the clamp around your chassis or stock, and use the pipe as the leverage to remove and install your barrel. Add some rubber to the jaws (another $2 at the hardware store) to avoid damage to your stock or chassis. We recommend clamping around the recoil lug/front action screw juncture, and proceeding with caution! When using this method you are transferring force from the clamp to the stock - and then from the stock to the action via the action screws and any bedding surrounding the recoil lug. We have had great success with this method and have not damaged anything, but the potential is there. Be especially cautious about using this method with a lightly built wood, fiberglass, or carbon fiber stock. In our testing we used this method on a bedded rifle in a chassis - and after 100 removals and installs at 80 ft-lb the bedding was still tight and showed no signs of being worse for the wear, nor did any other components.

"MPA ROD"

For those with the popular Masterpiece Arms chassis, there is a recess behind the grip that will ALMOST take a 1 1/2" x 1/2" piece of aluminum stock (as seen in the demo video at the top of the page). I purchased a 2 foot piece that size from the local metal supply for ~ $10, and then spend about 10 minutes with a flap disc on an angle grinder rounding off the edges and taking the last two inches down from .500" to .475" so it would slip into this recess. As with the pipe clamp method, you are transferring force through your action screws and bedding, so proceed with caution. For testing purposes, I installed and removed a barrel set to 120 ft-lbs using this method with no ill effects, however I absolutely do not recommend that much torque, nor do I take responsibility if you manage to damage your stock using this technique. Additionally, if you are particular about the finish on your chassis inside this pocket, this will scratch it slightly, so proceed with that knowledge

If you're interested, there's even more detail at the site I set up: www.rossprecisionmt.com.