Form 1 50bmg suppressor

After making my 408 can I was ready to make a can for my 50bmg. 50’s are fun to shoot but the muzzle blast is horrendous.

After seeing this video I wanted one similar in size. And decited to make it 18x3inches dia

http://www.youtube.com/watch?v=MxYpVIMYmCU

I wanted to make it out of stainless and I ordered materials from online metals.com.

I wanted to make it light as possible so I ordered the thinner wall .065 in 3inch dia.

http://www.onlinemetals.com/merchant.cfm...2&top_cat=1

and the bar material to make the baffles

http://www.onlinemetals.com/merchant.cfm...6&top_cat=1

I wanted the weight to come in at 6-7 pounds and thought the thinner wall would work and using aluminum spacers to cut the weight and provide more strength for the walls. I found some tubing that fit perfectly.

This would hold the baffles straight and make it lighter.

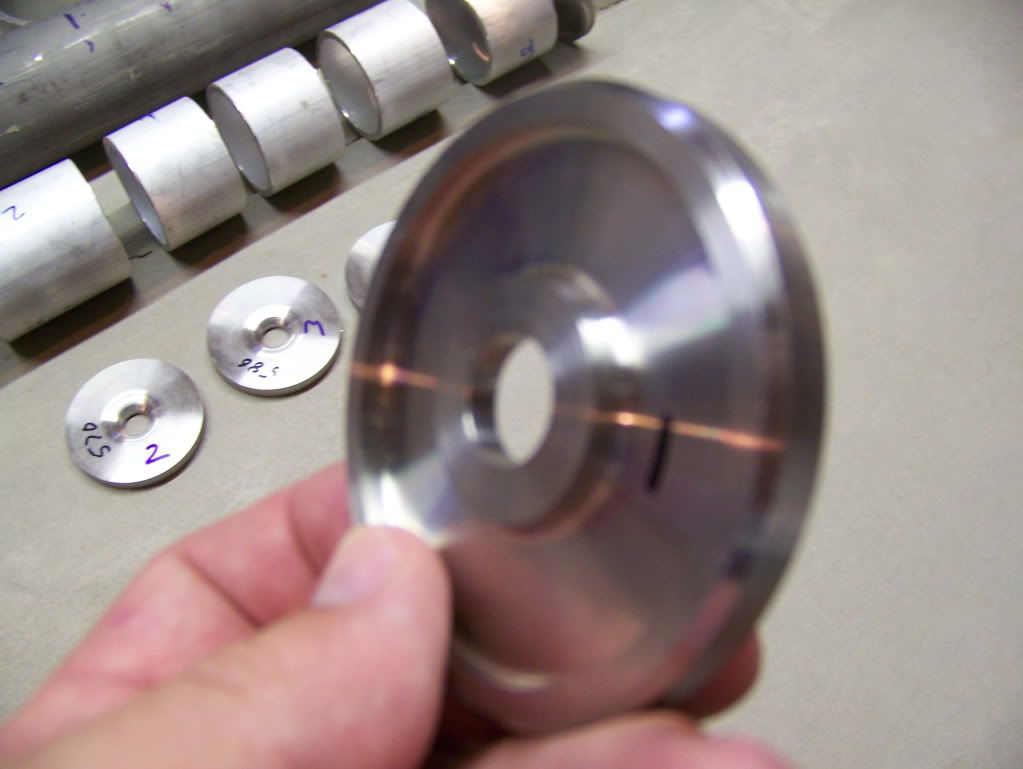

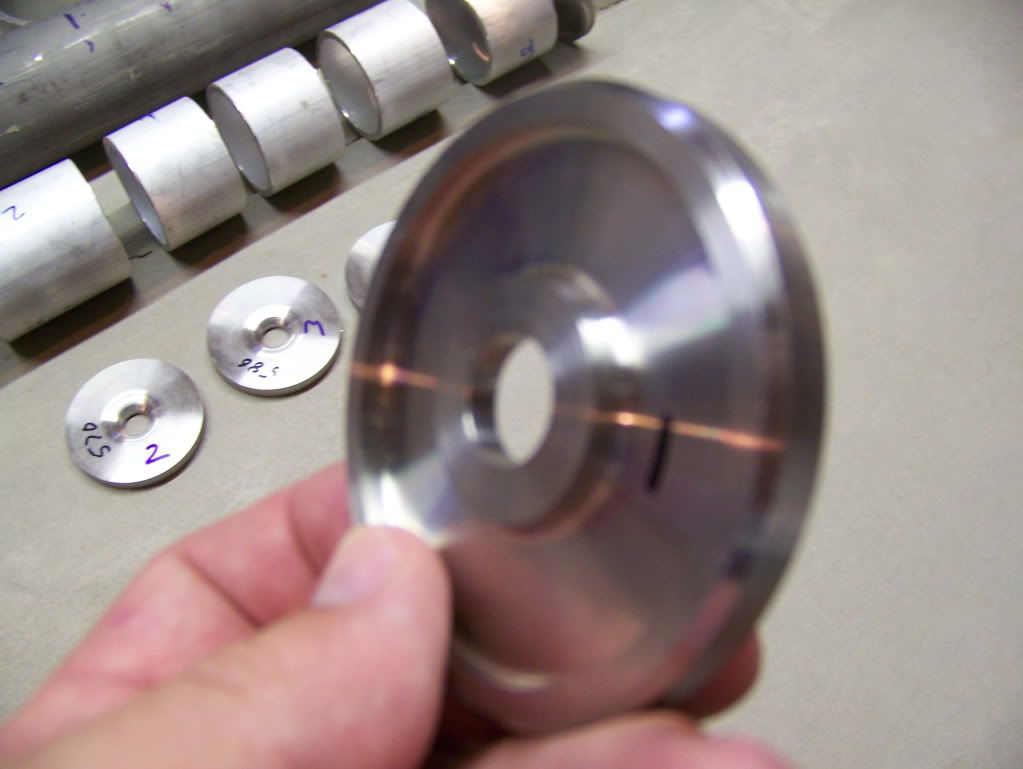

Baffles:

I went for a simple “tac16” design. 6 baffles and spacers. I thought more complicated ones would be heavier and harder to make.I originally was going to have 7 but dropped one to save weight. I back cut the holes to let the gas expand before hitting the next baffle and save weight.

I started with a .57 hole and ended with a .61 hole in the end. I “tapered” it to help avoid baffle strikes.

The baffles were simple but heavy to I turned off the “rim” of each one but the first one and it saved me half a pound in weight. The can still ended up being 8 pounds but being 18 inches long and 3 inches dia. I feel it came out pretty good.

I had a friend of mine tig weld it together:

It looked like he was working on a drive shaft not a suppressor!

It was now ready to me fired. My fired has a 55 gallon drum buried in his shop filled with sand and has rubber layers over it to set weapons so I fired a shot to see how she worked! I have to admit I was a little nervous before firing it but I was confident it would work.

http://www.youtube.com/watch?v=inhjxDfRxwA

I was pleasantly supprised with how well it sounded. Didn’t ring my hears and had a good tone. I fired a few more to make sure nothing was coming apart then drove out to on open area to see how it sounded away from the metal buildings.

http://www.youtube.com/watch?v=ATmYBmz8lx0

It was very pleasant to shoot with no muzzle blast and recoil was not bad at all.

The gun: Original Cheytac intervention (made by EDM arms) with 50bmg barrel conversion from EDM arms. (Switch barrel)

I have some more detail work to do on the can before I coat it but I’m psyched how well it came out and works. I have about 280$ into it and only about 10 hours of lathe work. The baffles were done on a CNC machine and after programmed took 7 minutes to make each. I love the fact that I made it my self and how well it works.

did I mention this is huge. I'm 6'7"....

After making my 408 can I was ready to make a can for my 50bmg. 50’s are fun to shoot but the muzzle blast is horrendous.

After seeing this video I wanted one similar in size. And decited to make it 18x3inches dia

http://www.youtube.com/watch?v=MxYpVIMYmCU

I wanted to make it out of stainless and I ordered materials from online metals.com.

I wanted to make it light as possible so I ordered the thinner wall .065 in 3inch dia.

http://www.onlinemetals.com/merchant.cfm...2&top_cat=1

and the bar material to make the baffles

http://www.onlinemetals.com/merchant.cfm...6&top_cat=1

I wanted the weight to come in at 6-7 pounds and thought the thinner wall would work and using aluminum spacers to cut the weight and provide more strength for the walls. I found some tubing that fit perfectly.

This would hold the baffles straight and make it lighter.

Baffles:

I went for a simple “tac16” design. 6 baffles and spacers. I thought more complicated ones would be heavier and harder to make.I originally was going to have 7 but dropped one to save weight. I back cut the holes to let the gas expand before hitting the next baffle and save weight.

I started with a .57 hole and ended with a .61 hole in the end. I “tapered” it to help avoid baffle strikes.

The baffles were simple but heavy to I turned off the “rim” of each one but the first one and it saved me half a pound in weight. The can still ended up being 8 pounds but being 18 inches long and 3 inches dia. I feel it came out pretty good.

I had a friend of mine tig weld it together:

It looked like he was working on a drive shaft not a suppressor!

It was now ready to me fired. My fired has a 55 gallon drum buried in his shop filled with sand and has rubber layers over it to set weapons so I fired a shot to see how she worked! I have to admit I was a little nervous before firing it but I was confident it would work.

http://www.youtube.com/watch?v=inhjxDfRxwA

I was pleasantly supprised with how well it sounded. Didn’t ring my hears and had a good tone. I fired a few more to make sure nothing was coming apart then drove out to on open area to see how it sounded away from the metal buildings.

http://www.youtube.com/watch?v=ATmYBmz8lx0

It was very pleasant to shoot with no muzzle blast and recoil was not bad at all.

The gun: Original Cheytac intervention (made by EDM arms) with 50bmg barrel conversion from EDM arms. (Switch barrel)

I have some more detail work to do on the can before I coat it but I’m psyched how well it came out and works. I have about 280$ into it and only about 10 hours of lathe work. The baffles were done on a CNC machine and after programmed took 7 minutes to make each. I love the fact that I made it my self and how well it works.

did I mention this is huge. I'm 6'7"....