Re: forster coax press issue

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Clark</div><div class="ubbcode-body">

I had a problem with the springs flying when I changed jaws.

I had a problem with the shell holder jaw housing getting bent from pulling stuck cases out of the sizer die. Once it is bent with a hump in the middle, each case must be hand guided into the die. The housings are just cast steel with thin edges.

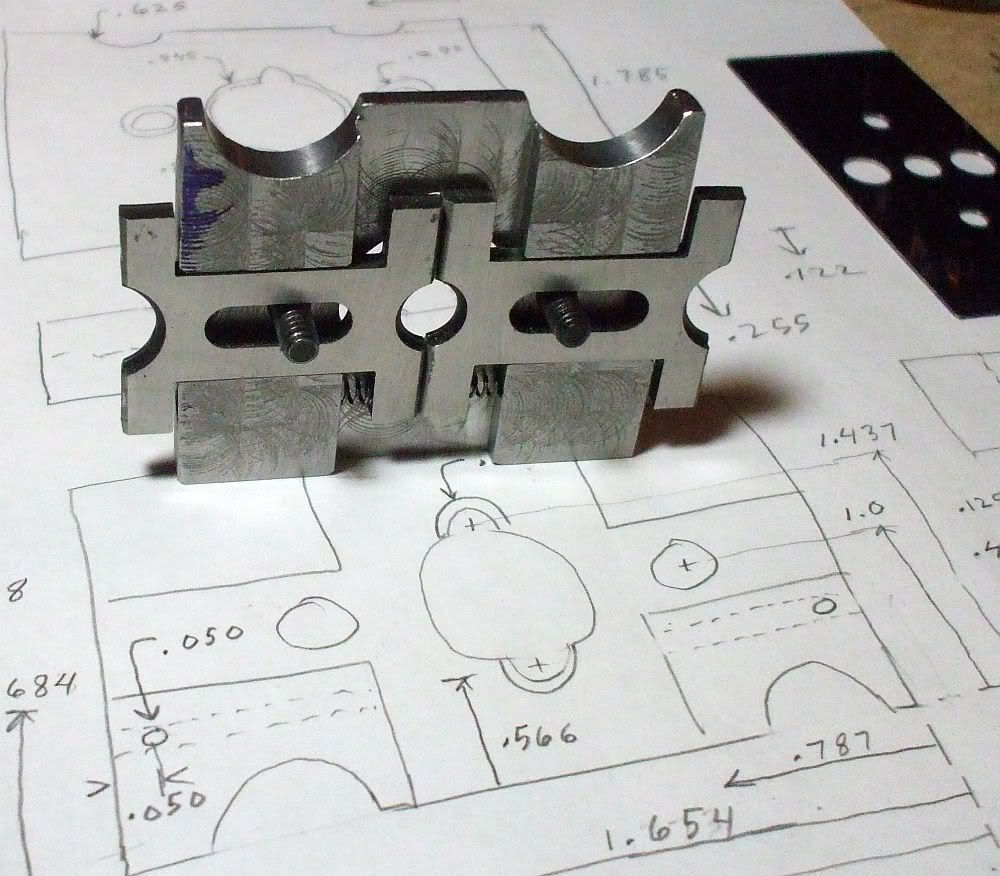

So I made some shell holder jaw housings.

Can you see how those springs are not going anywhere?

Can you see how that shell holder jaw housing is not going to bend? </div></div>

Clark I do see the advantages of that housing--very nice. It is out of my ability, contact base, to build or have built one of those. I would be VERY interested to obtain one from you. If you are willing, just shoot me a message and I'd be happy to pay you for one if you would be willing to build me one, in fact two or three, I will have another Co-ax in my room eventually, and my best friend has one!

Ron, I looked and my press DOES have the centering screw. I fooled with it some and it helped--significantly--problem is, it will not reliably extract a case that has been full length resized with that pin engaged with the jaws....

My original owners manual is not the one you provided a link to, it doesn't even mention the centering screw--??. I was able to get MUCH better results by engaging the jaws with it slightly, but the manual says it is for bullet seating only, which I get, beause having the screw holding the jaws slightly apart, will make a huge difference in the shellholders ability to grip a case firmly, which is needed for sizing operations. Without that pin engaged, the shellholder simply grips the case inconsistently, and it tilts this way and that irregularly. I took the wear plate, shellholder jaws, and shellholder housing, and placed them on a flat steel machinists plate, and they look pretty square, not perfect mind you, but pretty square. I 'lapped' the shellholder jaws and wear plate on both sides with some diamond whetstones, and they smoothed up a little bit, but by the even wear patterns from the 'lapping', I'd say they aren't bent--certainly not significantly....I'm thinking the jaw Housing is the culprit, I don't know why it would be, but it sems to be the part of the equation that I can't verify, and if anything is bent, it could be that--again I have no idea how though....I put it on the machinists plate, and can't discern a lot of 'out of square' on it, but I put a heavy steel block on top of it, hammered on top of the steel block with a rubber mallet to try and square it up--did this both sides, maybe slightly more square, but no effect on the result....at this point I am going to run it with the centering screw pin engaged and order another set of jaws and springs as well as a new housing, assuming Forster will sell them to me....

Frustrating for sure, I really love my Coax, but this is a real PITA!