I have a seating die doing the same thing with the mushroomed stem. I sent it back to them. They said they fixed it. 20 rounds into seating and it mushroomed again. Its smack dab in the middle of competition season. Called them on Monday and left a message. They called me back and Tuesday and said they would have to talk to the technician and give me a call back. Still nothing!! I had to buy a Hornady seating die locally that I had to modify the seating stem on but it worked way better than the Forster that wouldn't seat accurately because of the stem. Ordered a Redding competition seating die with a long VLD stem. Its not here yet but hopefully it will work for me. When it gets here I will have 3 seating dies for the 6.5CM, Forster is now a paper weight, Hornady is modified but works, and hopefully Redding will be a winner.This has been my experience as well.

The original press crushed the spent primer tube. Since redesigned. They will not send replacement parts for the original screwed up design unless I ship them the part at my expense.

Last two seating dies had out of spec seating stems. One failed on the first pull of the handle. The seating cup mushroomed on the second. Same story: send us the part at your expense and we will think about replacing it. This means my co-ax press is unusable for weeks at a time.

Complete dicks describes their customer service accurately.

Unusual in an industry known for outstanding customer service. DILLON they are not.

I have had zero problems with dies from three other suppliers for a dozen or more calibers.

Buyer beware.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Forster Micrometer Seating Die Issue

- Thread starter butlerotis

- Start date

Man yall both must have got a bad rep I got a guy sent me a free seating stem to see if it worked better before he had me send all my stuff in to them to check my issue free of charge.This has been my experience as well.

The original press crushed the spent primer tube. Since redesigned. They will not send replacement parts for the original screwed up design unless I ship them the part at my expense.

Last two seating dies had out of spec seating stems. One failed on the first pull of the handle. The seating cup mushroomed on the second. Same story: send us the part at your expense and we will think about replacing it. This means my co-ax press is unusable for weeks at a time.

Complete dicks describes their customer service accurately.

Unusual in an industry known for outstanding customer service. DILLON they are not.

I have had zero problems with dies from three other suppliers for a dozen or more calibers.

Buyer beware.

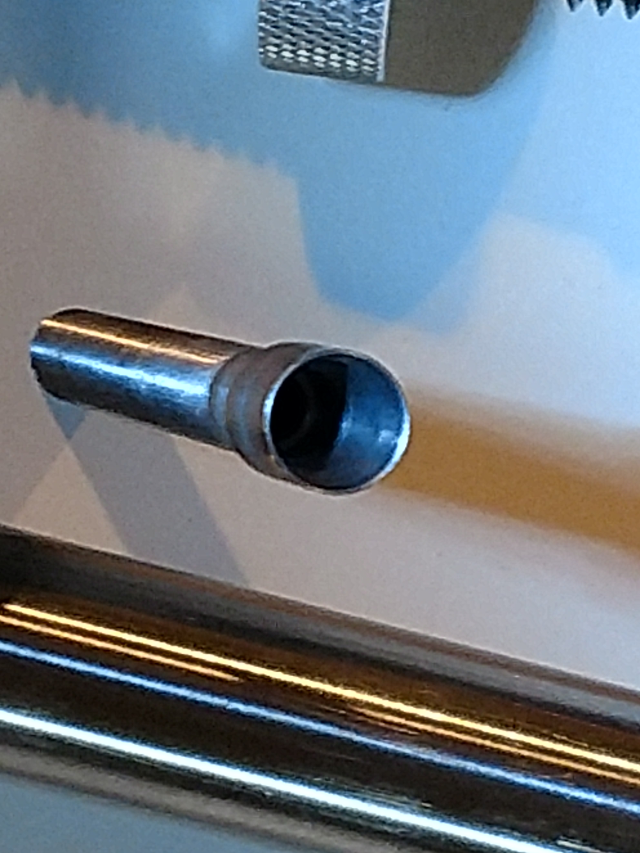

Yes you do. I had one of the older hardened stems and it cracked like yours. I purchased the new “beefier” non-hardened seating stems and it mushroomed at the mouth of the stem creating wildly different seating depths and a groove in the alignment sleeve.within 30 rounds of seating with .0015 neck tension and almost no resistance in seating. Like I said above still waiting on a call back from the beginning of the week. I have no idea what to think of Forster at this point.Just pulled mine apart to inspect and it seems like I have a split in the seating cup. Took a few pictures to try and show it.

View attachment 6921764

View attachment 6921766View attachment 6921768

Sent an email to Forster this morning and within an hour this informative reply and said they will send a new one out to me.

There are a number of things that could have caused this issue and should prompt perhaps a few things to be checked prior the use of a new Seating Stem. The most important of which, is being sure that a bullet will pass cleanly through the bullet channel of the spring loaded silver chamber when the top of the die is removed, if not, a new stem will quickly break again. We also would need to know if this is a micrometer seater or standard bench rest seater as they are threaded differently.

1) The die has a bullet channel that is .0005" over the bullet diameter, this is one of the true advantages of the Die, however if you encounter a batch of slightly over-sized bullets that are not passing cleanly through the tight tolerance channel then the increase pressure it can damage the stem. To check this, remove the top of the die and assure that your bullets drop through the top of the silver spring loaded chamber freely.

2) If there is excessive run-out on the resized cases this can bring the case necks out of alignment with the bullet channel and increase the pressure between the stem and bullet.

3) Assure the cases do not have excessive neck tension. Often times brand new brass can have excessive neck tension and needs to be resized using an Expander Ball prior to reloading, it can also be riddled with burrs that should be removed as well. When checking the Die for accurate seating, do so with once fired resized cases, your rifle will greatly assist in being sure that all cases are uniform.

4) Avoid compressed loads, again the added pressure can cause damage.

5) Our Seating Stems are Heat Treated, which makes them very durable during the normal reloading process. If jarred severally from dropping, or excessively rough handling during the shipping process, there is potential that the stem could crack and this would allow the stem to flare out and form to the bullet profile, creating sticking and varying seating depths.

We look forward to assisting you further with this, if you decided to send this in for review, send the components to:

FORSTER PRODUCTS

310 E. Lanark Ave.

Lanark, IL 61046

Scott

FORSTER PRODUCTS

1) The die has a bullet channel that is .0005" over the bullet diameter, this is one of the true advantages of the Die, however if you encounter a batch of slightly over-sized bullets that are not passing cleanly through the tight tolerance channel then the increase pressure it can damage the stem. To check this, remove the top of the die and assure that your bullets drop through the top of the silver spring loaded chamber freely.

2) If there is excessive run-out on the resized cases this can bring the case necks out of alignment with the bullet channel and increase the pressure between the stem and bullet.

3) Assure the cases do not have excessive neck tension. Often times brand new brass can have excessive neck tension and needs to be resized using an Expander Ball prior to reloading, it can also be riddled with burrs that should be removed as well. When checking the Die for accurate seating, do so with once fired resized cases, your rifle will greatly assist in being sure that all cases are uniform.

4) Avoid compressed loads, again the added pressure can cause damage.

5) Our Seating Stems are Heat Treated, which makes them very durable during the normal reloading process. If jarred severally from dropping, or excessively rough handling during the shipping process, there is potential that the stem could crack and this would allow the stem to flare out and form to the bullet profile, creating sticking and varying seating depths.

We look forward to assisting you further with this, if you decided to send this in for review, send the components to:

FORSTER PRODUCTS

310 E. Lanark Ave.

Lanark, IL 61046

Scott

FORSTER PRODUCTS

I have a seating die doing the same thing with the mushroomed stem. I sent it back to them. They said they fixed it. 20 rounds into seating and it mushroomed again. Its smack dab in the middle of competition season. Called them on Monday and left a message. They called me back and Tuesday and said they would have to talk to the technician and give me a call back. Still nothing!! I had to buy a Hornady seating die locally that I had to modify the seating stem on but it worked way better than the Forster that wouldn't seat accurately because of the stem. Ordered a Redding competition seating die with a long VLD stem. Its not here yet but hopefully it will work for me. When it gets here I will have 3 seating dies for the 6.5CM, Forster is now a paper weight, Hornady is modified but works, and hopefully Redding will be a winner.

I have zero issues with my Redding comp seating die & the VLD stem

I did everything they are suggesting and am still having problems.

I suspect a bad batch of heat annealed seating stems.

It still annoys me that they expect a customer to spend $10 to send them their bad parts.

Very unusual to see such indifferent customer service in this industry.

I suspect a bad batch of heat annealed seating stems.

It still annoys me that they expect a customer to spend $10 to send them their bad parts.

Very unusual to see such indifferent customer service in this industry.

You crack a seating stem on a redding, you'll get the same shit. The finger will be pointed at you, compressed loads, no chamfer, etc... I am lost on dropping the packaged die during shipping, the dude probably should have omitted that little tidbit of wisdom, "yes, our seating stems are that fucking weak" lmaoI did everything they are suggesting and am still having problems.

I suspect a bad batch of heat annealed seating stems.

It still annoys me that they expect a customer to spend $10 to send them their bad parts.

Very unusual to see such indifferent customer service in this industry.

I have a seating die doing the same thing with the mushroomed stem. I sent it back to them. They said they fixed it. 20 rounds into seating and it mushroomed again. Its smack dab in the middle of competition season. Called them on Monday and left a message. They called me back and Tuesday and said they would have to talk to the technician and give me a call back. Still nothing!! I had to buy a Hornady seating die locally that I had to modify the seating stem on but it worked way better than the Forster that wouldn't seat accurately because of the stem. Ordered a Redding competition seating die with a long VLD stem. Its not here yet but hopefully it will work for me. When it gets here I will have 3 seating dies for the 6.5CM, Forster is now a paper weight, Hornady is modified but works, and hopefully Redding will be a winner.

Unless Redding have changed their seating dies they are more prone to the mushroomed seating stem than most.

I have had good luck with Forster BR seaters, but most of mine are more than a few years old. Excessive neck tension and/or compressed loads can contribute to the problem.

There can be problems with inconsistent neck wall thickness of the brass too.

I’m using Alpha brass. I admittedly had .003-.004 neck tension that cracked the first stem. The second stem mushroomed at .0015 neck tension. I’m at a loss.Unless Redding have changed their seating dies they are more prone to the mushroomed seating stem than most.

I have had good luck with Forster BR seaters, but most of mine are more than a few years old. Excessive neck tension and/or compressed loads can contribute to the problem.

There can be problems with inconsistent neck wall thickness of the brass too.

Very confusing. I've had my Forster BR seater for several years and have loaded at least two thousand rounds with it. Zero problems and awesomely low runout.

Since I hadn't cleaned the die in ages, I decided to pull it apart, clean, and oil it.

No cracks, no mushrooming.

Either Redding has suffered a serious QA/engineering problem recently or there is a setup problem.

One thing I did notice. The die chamber that the seating stem sits in has a very, very tight tolerance. To return the stem to the sleeve, I had to insert it threaded rod first. I can't understand how the stem can mushroom if it is properly positioned in the die chamber. The chamber bore itself must be very close to .309" since a .308 bullet "just" slips through it.

I'll have to play with it some more to see if I can find out when and how the stem descends below the "bore" of the die chamber into the lower part that is machined to guide the cartridge case itself. The best I can figure, that area of the die is the only place a stem could be damaged b the bullet.

Here's a link to the Forster diagram of the die:

https://www.forsterproducts.com/wp-content/uploads/Bench-Reset-Seater-Dies.png

Regardless, those of you who encountered less than helpful phone support technicians should definitely complain. There is no place for that in business.

Since I hadn't cleaned the die in ages, I decided to pull it apart, clean, and oil it.

No cracks, no mushrooming.

Either Redding has suffered a serious QA/engineering problem recently or there is a setup problem.

One thing I did notice. The die chamber that the seating stem sits in has a very, very tight tolerance. To return the stem to the sleeve, I had to insert it threaded rod first. I can't understand how the stem can mushroom if it is properly positioned in the die chamber. The chamber bore itself must be very close to .309" since a .308 bullet "just" slips through it.

I'll have to play with it some more to see if I can find out when and how the stem descends below the "bore" of the die chamber into the lower part that is machined to guide the cartridge case itself. The best I can figure, that area of the die is the only place a stem could be damaged b the bullet.

Here's a link to the Forster diagram of the die:

https://www.forsterproducts.com/wp-content/uploads/Bench-Reset-Seater-Dies.png

Regardless, those of you who encountered less than helpful phone support technicians should definitely complain. There is no place for that in business.

The Forster diagram of the die is interesting.

The problems I am having is with heavy and therefore long for caliber bullets seated longer than SAAMI COAL.

I wonder if modern, high BC, therefore long bullets also seated out to the lands don’t play well in the Forester seating die.

I agree the only way the seating stems can mushroom is if it contacts the bullet outside the bore of the die.

It’s not clear from the diagram how that could be happening with longer COAL. From memory the stem falls below the bore earlier than shown in the diagram.

Time to pull a die apart.

The problems I am having is with heavy and therefore long for caliber bullets seated longer than SAAMI COAL.

I wonder if modern, high BC, therefore long bullets also seated out to the lands don’t play well in the Forester seating die.

I agree the only way the seating stems can mushroom is if it contacts the bullet outside the bore of the die.

It’s not clear from the diagram how that could be happening with longer COAL. From memory the stem falls below the bore earlier than shown in the diagram.

Time to pull a die apart.

Interesting. I can see how shorter bullets might bring the stem out of the chamber bore, but to accommodate a longer bullet I would think the stem would be going up farther into the protective bore.

What bullet are you seating?

What bullet are you seating?

Interesting. I can see how shorter bullets might bring the stem out of the chamber bore, but to accommodate a longer bullet I would think the stem would be going up farther into the protective bore.

What bullet are you seating?

That sounds right.

My problems have been with the 147 ELD-M in 6.5 CM and the 200 LRX for .300 WM both loaded long.

Have you tried this?

Completely disassemble the die (make a note of the existing positions of the die body, seating stem rod, and micrometer if you have one).

See if a bullet in question easily passes through the chamber die bore from the stem rod side.

On my .308 seater, the Nosler Custom Competition bullet bearing surface fits into the bore almost exactly and easily slides all the way through. It's not loose or tight, just a perfect lit like a well machined bearing.

I'm just curious to see if your die chamber bore is the same.

Completely disassemble the die (make a note of the existing positions of the die body, seating stem rod, and micrometer if you have one).

See if a bullet in question easily passes through the chamber die bore from the stem rod side.

On my .308 seater, the Nosler Custom Competition bullet bearing surface fits into the bore almost exactly and easily slides all the way through. It's not loose or tight, just a perfect lit like a well machined bearing.

I'm just curious to see if your die chamber bore is the same.

Have you tried this?

Completely disassemble the die (make a note of the existing positions of the die body, seating stem rod, and micrometer if you have one).

See if a bullet in question easily passes through the chamber die bore from the stem rod side.

On my .308 seater, the Nosler Custom Competition bullet bearing surface fits into the bore almost exactly and easily slides all the way through. It's not loose or tight, just a perfect lit like a well machined bearing.

I'm just curious to see if your die chamber bore is the same.

I wouldn’t call it a perfect fit, but a bullet will slide all the way through the bore.

The mushroomed seater will not of course.

I am traveling for a few weeks, but will take a closer look when I’m back in my reloading room.

Ran 8 prepped cases through the new seating die this morning. It was nice to see the consistency even on a progressive Dillon 550 press. Forster stepped up and sent a new stem right away without requiring me to send my damaged one back. They did say I could send it if I wanted to. Great customer service over the years using their dies, honing to size and questions I've asked.

The last thread I needed to come across! Because I have been waiting since April for my Forster Micro Seating Die. Received word it is shipped and will get it in a couple days. LOL. Thanx Blowby for your post, was good to read. But, am saving the link to this thread, just_in_case.

Good luck on the new die. I recommend when you get it, thoroughly disassemble and clean it. It might be a good idea to take a bullet of the appropriate caliber and test it's clearance through the upper bore of the die chamber. I believe it should be a very close tolerance, but the bullet should easily pass through the bore. If not, you've got a problem. Likewise, if the seater stem is rough, it should be polished before using. The stem should have a close tolerance in the bore, but not be hard to move.

One thought. To get an idea of how the seating stem is going to seat your bullet, you might run a handful of them through a micrometer measurement between the upper stem rim and bullet base, I believe there's just enough lip on the rod side of the stem to grab it with the micrometer. At there very least, doing this will give you an idea of where the stem hits the bullet in comparison to where your ogive comparator hits it.

Post pictures. We can build a reference library here for folks to compare with.

I'm tempted to order a new stem even though mine appears to work ok. I sure like the look of the new one Blowby posted the pic of.

One thought. To get an idea of how the seating stem is going to seat your bullet, you might run a handful of them through a micrometer measurement between the upper stem rim and bullet base, I believe there's just enough lip on the rod side of the stem to grab it with the micrometer. At there very least, doing this will give you an idea of where the stem hits the bullet in comparison to where your ogive comparator hits it.

Post pictures. We can build a reference library here for folks to compare with.

I'm tempted to order a new stem even though mine appears to work ok. I sure like the look of the new one Blowby posted the pic of.

They have stopped making the black hardened stems and are now shipping the SS looking stems. I have talked to them recently at length about this. My newest seating stem with 140 ELD’s is working better than the last one but I’m still having problems. I got the felt seating pressure down by adding NU Finish to my corn cob when tumbling as suggested by a member earlier in this thread. They seat like butter but there are still a few rounds here and there that have a slight bit more pressure. By slight I mean almost imperceptible.Good luck on the new die. I recommend when you get it, thoroughly disassemble and clean it. It might be a good idea to take a bullet of the appropriate caliber and test it's clearance through the upper bore of the die chamber. I believe it should be a very close tolerance, but the bullet should easily pass through the bore. If not, you've got a problem. Likewise, if the seater stem is rough, it should be polished before using. The stem should have a close tolerance in the bore, but not be hard to move.

One thought. To get an idea of how the seating stem is going to seat your bullet, you might run a handful of them through a micrometer measurement between the upper stem rim and bullet base, I believe there's just enough lip on the rod side of the stem to grab it with the micrometer. At there very least, doing this will give you an idea of where the stem hits the bullet in comparison to where your ogive comparator hits it.

Post pictures. We can build a reference library here for folks to compare with.

I'm tempted to order a new stem even though mine appears to work ok. I sure like the look of the new one Blowby posted the pic of.

The problem is when I first started using the new seating stem the CBOG kept drifting longer about every 20 rounds for about the first 100 rounds. I kept adjusting the micrometer to shorter lengths by several thousands every 20 rounds. At around the 100 round mark it seemed to stabilize and I was able to seat almost 100 rounds without adjusting it at all but had an ES of .003 CBOG. I believe what’s happening is that the seating stem cup is actually flexing under pressure and expanding . Hard to get consistent seating when the stem cup is flexing outward on the top of the bullet.

Freshly annealed cases, .002 neck tension, Prime brass

I’m kind of at a loss. I’ve received my Redding die and will try using that on my next batch in a couple of weeks.

They have stopped making the black hardened stems and are now shipping the SS looking stems. I have talked to them recently at length about this. My newest seating stem with 140 ELD’s is working better than the last one but I’m still having problems. I got the felt seating pressure down by adding NU Finish to my corn cob when tumbling as suggested by a member earlier in this thread. They seat like butter but there are still a few rounds here and there that have a slight bit more pressure. By slight I mean almost imperceptible.

The problem is when I first started using the new seating stem the CBOG kept drifting longer about every 20 rounds for about the first 100 rounds. I kept adjusting the micrometer to shorter lengths by several thousands every 20 rounds. At around the 100 round mark it seemed to stabilize and I was able to seat almost 100 rounds without adjusting it at all but had an ES of .003 CBOG. I believe what’s happening is that the seating stem cup is actually flexing under pressure and expanding . Hard to get consistent seating when the stem cup is flexing outward on the top of the bullet.

Freshly annealed cases, .002 neck tension, Prime brass

I’m kind of at a loss. I’ve received my Redding die and will try using that on my next batch in a couple of weeks.

That is odd. From my inspection of my die and the Forster diagram, a properly adjusted stem should ride up in down in the die chamber bore which should have a tolerance of around .001. Theoretically, since the stem sits in the chamber bore, it should not be able to flex, at least not more than the tolerance of the chamber bore. Is your stem undersize, or the chamber bore oversize? When your die is adjusted for the desired CBOG, is the stem inside or below the bore?

I recommend checking the diameter of the stem with a micrometer and measure the die chamber bore as well.

I'm looking forward to your results with the Redding die. If there's not a thread on the Redding, please start one.

Thanks.

*** I should add that all of my bullets are tumbled in ceramic beads coated with hexagonal boron nitride powder (hBN), which makes them extremely slippery.

I just inspected my die. I didn’t take it apart to mic any of the components. Yes the stem is fully inside of the die chamber when at rest and when seating. When I inspected the portion of the sleeve where the seating stem rides and the seating stem cup is actually scratching the inside of the sliding chamber thus proving the point the the stem is indeed flexing under minimal seating pressures. Even a small flex of .0005 would give you exponentially longer seating depths because the bullet is obviously cone shaped and as it slides farther down each bullet as it expands seating depths get longer.That is odd. From my inspection of my die and the Forster diagram, a properly adjusted stem should ride up in down in the die chamber bore which should have a tolerance of around .001. Theoretically, since the stem sits in the chamber bore, it should not be able to flex, at least not more than the tolerance of the chamber bore. Is your stem undersize, or the chamber bore oversize? When your die is adjusted for the desired CBOG, is the stem inside or below the bore?

I recommend checking the diameter of the stem with a micrometer and measure the die chamber bore as well.

I'm looking forward to your results with the Redding die. If there's not a thread on the Redding, please start one.

Thanks.

*** I should add that all of my bullets are tumbled in ceramic beads coated with hexagonal boron nitride powder (hBN), which makes them extremely slippery.

This is again is a new seating stem and has 250 rounds seated with it. I had an idea the other day that maybe someone could start making custom seating stems out of titanium or some other metal that would hold up. I heard that Whidden uses delron or some similar very hard plastic in the end of their seating stem to avoid this problem. Don’t know if this is true or not.

I just inspected my die. I didn’t take it apart to mic any of the components. Yes the stem is fully inside of the die chamber when at rest and when seating. When I inspected the portion of the sleeve where the seating stem rides and the seating stem cup is actually scratching the inside of the sliding chamber thus proving the point the the stem is indeed flexing under minimal seating pressures. Even a small flex of .0005 would give you exponentially longer seating depths because the bullet is obviously cone shaped and as it slides farther down each bullet as it expands seating depths get longer.

This is again is a new seating stem and has 250 rounds seated with it. I had an idea the other day that maybe someone could start making custom seating stems out of titanium or some other metal that would hold up. I heard that Whidden uses delron or some similar very hard plastic in the end of their seating stem to avoid this problem. Don’t know if this is true or not.

Fascinating. I guess I am better off polishing my old style hardened stem then. I've been pretty lucky so far reloading .308 with it. I take it by your description, you're loading .264, which is a far longer bullet.

From your description, I would be willing to bet that the bore gap between the stem and chamber are greater than .0005. I wonder if chrome electro-plating on the outside of the stem would help?

Regardless, perhaps this is a great after-market manufacturing opportunity - using a CNC to turn out improved seating stems for dies.

THis. A couple of thou difference is normal but all it takes is a little more pressure on the handle and you will seat the bullet a good bit deeper than if you used less pressure. Be methodical with your seating stroke!I think it has to be the pressure I am applying to the press because I went and tried 10 more just to be sure and went very slow and applied the same pressure on the ram and all but one bulelt came out to 2.285 base to ogive and the odd ball came out 2.2835 just a little bit shorter.

Received my Forster Ultra Micrometer Seating die a couple days ago and used it to load up some cartridges. I followed the directions and cleaned it. I also successfully test dropped the four bullets I load with down its throat and all went thru. I am sorry I did not photograph it. The seating stem was charcoal gray in color and did not appear to be SS (shiney).

The seating stem/die did not do any damage to my bullets nor the bullets damage the seating stem's mouth. I only had a little trouble getting it to work the way I expected but after some experience, trial and error, and practice it works as advertized. It seated the bullets just fine and when I wanted to I could use the micrometer feature to adjust depth. I am thankful.

I ordered the die from Optics Planet back in March, on sale for $73. Finally received it this month (July). I also ordered their FL sizing die in April which was still back ordered , so cancelled that order. I have a seating die and also bought a Forster neck bushing die from another source in the meantime.

The seating stem/die did not do any damage to my bullets nor the bullets damage the seating stem's mouth. I only had a little trouble getting it to work the way I expected but after some experience, trial and error, and practice it works as advertized. It seated the bullets just fine and when I wanted to I could use the micrometer feature to adjust depth. I am thankful.

I ordered the die from Optics Planet back in March, on sale for $73. Finally received it this month (July). I also ordered their FL sizing die in April which was still back ordered , so cancelled that order. I have a seating die and also bought a Forster neck bushing die from another source in the meantime.

Last edited:

I used my Redding Competition seating die with VLD stem yesterday. It worked very well!! I seated 60 rounds and they had a seating depth ES of .002. I just think the seating stems that Forster has switched to are not a good thing!

The die that LG65CM received had the hardened stem in it which I had good look with until it cracked and they replaced it with the non-hardened version.

The die that LG65CM received had the hardened stem in it which I had good look with until it cracked and they replaced it with the non-hardened version.

I bought Forster Ultra Micrometer seater die for 223 Rem last month. After loading about 40 rds, the ss stem sticking bullets and stem cup expanding. I load 23.4 Varget on 77 gr bullet in un annealed brass. I pulled the stem out the sleeve. I'm wondering if I can harden the stem to make it hardener or only work on annealed brasses.

Let forster know, theyll send you a new one. I bet if you look really close youll find it cracked if its popping really hard. At least mine had.I bought Forster Ultra Micrometer seater die for 223 Rem last month. After loading about 40 rds, the ss stem sticking bullets and stem cup expanding. I load 23.4 Varget on 77 gr bullet in un annealed brass. I pulled the stem out the sleeve. I'm wondering if I can harden the stem to make it hardener or only work on annealed brasses.

Thank you, spide7980. After I sent msg to them, I got this reply " it sounds as if the seater encountered some extra pressure. I would recommend sending the die into us with a couple sample cases you have resized/unprimed and a couple samples of the bullets you are using to the address"

I see their website and they have the stem about $15. I just ordered one with total about $21. I may sell it after I get the new stem. I have no interest to fix their problem. I may try L.E. Wilson or Redding instead. The store I bought from Amazon, they will charge about 20% restocking fee. It's not new problem from Forster seating die and I don't think they can fix it anyway.

I see their website and they have the stem about $15. I just ordered one with total about $21. I may sell it after I get the new stem. I have no interest to fix their problem. I may try L.E. Wilson or Redding instead. The store I bought from Amazon, they will charge about 20% restocking fee. It's not new problem from Forster seating die and I don't think they can fix it anyway.

Similar threads

- Replies

- 3

- Views

- 205

Reloading Equipment

Forster micrometer seating 6BR

- Replies

- 10

- Views

- 318

Reloading Equipment

6BR/A Dies - Forster Micrometer - Whidden FL Sizer

- Replies

- 1

- Views

- 109

- Replies

- 0

- Views

- 72