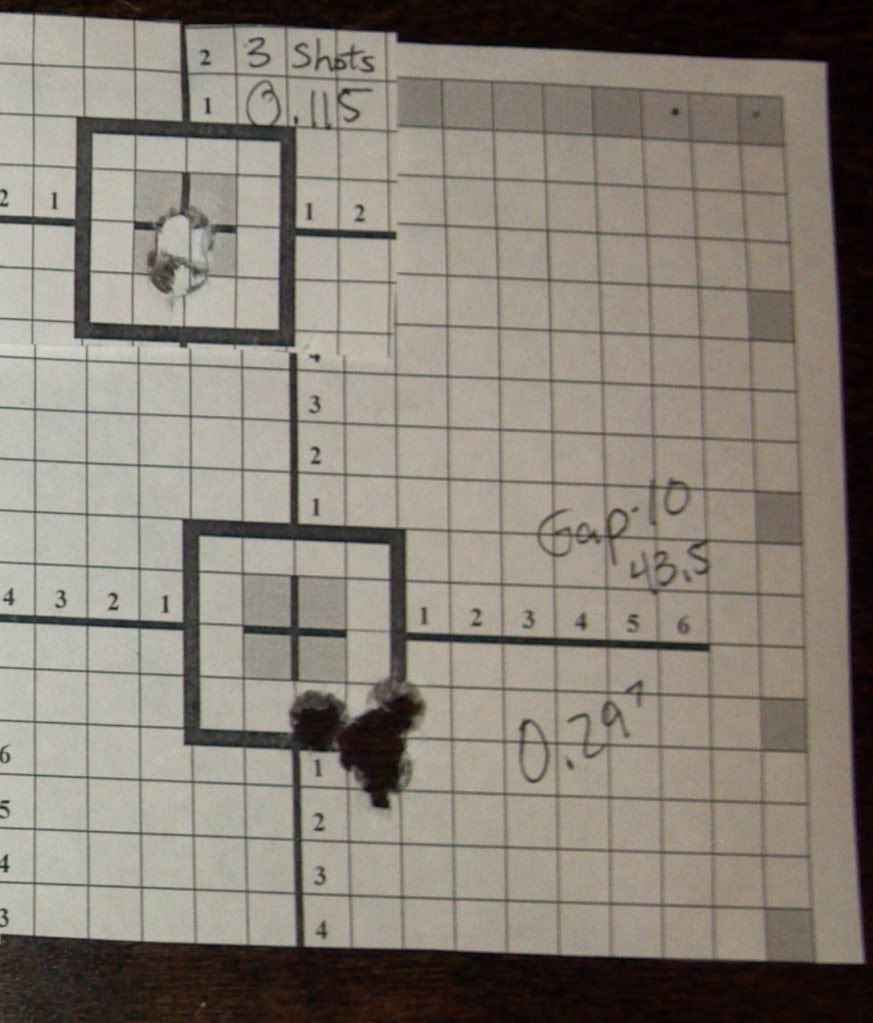

I originally started a thread in the reloading section about the results of my ladder test with some of my reloads, but it sort of turned into a thread about issues I've been having with pierced primers and my 308 GAP-10.

Original thread here:

http://www.snipershide.com/shooting/showthread.php?t=178699

To re-cap my first 100 rounds through the rifle where all factory FGMM 175gr SMK's. Of those rounds about 50 percent of them experienced pierced primers. I switched over to a different lot of FGMM, and although I've experenced no pierced primers, I do have heavy cratering of the primer. The few reloads that I have tried have all experienced a mix of heavy cratering and pierced primers. All the heat and blow back from the pierced primers have left my firing pin a pitted mess. When I talked to GAP last week they said it sounded like an ammo issue.

Two weeks ago I sent the remaining lot of FGMM that I had originally experienced all the pierced primers with back to ATK/Federal ammo. Which have been awesome to deal with by the way. Today I got the results back from Federal. Of the 5 boxes I sent back to them, all the ammo tested perfect with and average pressure of 58,834psi with spec of 60,000psi. All cases were within tollerance as well. Their opinion was that my rifle has headspace issues.

The rifle functions fine until I have a pierced primer, after which every round there after experiences a pierced primer. I have to dis-assembly the bolt carrier to find the little piece of primer brass caught in the firing pin area of the bolt, to get the rifle to function normally again.

So my question is, where do I turn from here? Send it back to GAP? Send the bolt to Gre-tan for a bushing job and custom firing pin? I could use a little advice here.

Thank, Powereng

Original thread here:

http://www.snipershide.com/shooting/showthread.php?t=178699

To re-cap my first 100 rounds through the rifle where all factory FGMM 175gr SMK's. Of those rounds about 50 percent of them experienced pierced primers. I switched over to a different lot of FGMM, and although I've experenced no pierced primers, I do have heavy cratering of the primer. The few reloads that I have tried have all experienced a mix of heavy cratering and pierced primers. All the heat and blow back from the pierced primers have left my firing pin a pitted mess. When I talked to GAP last week they said it sounded like an ammo issue.

Two weeks ago I sent the remaining lot of FGMM that I had originally experienced all the pierced primers with back to ATK/Federal ammo. Which have been awesome to deal with by the way. Today I got the results back from Federal. Of the 5 boxes I sent back to them, all the ammo tested perfect with and average pressure of 58,834psi with spec of 60,000psi. All cases were within tollerance as well. Their opinion was that my rifle has headspace issues.

The rifle functions fine until I have a pierced primer, after which every round there after experiences a pierced primer. I have to dis-assembly the bolt carrier to find the little piece of primer brass caught in the firing pin area of the bolt, to get the rifle to function normally again.

So my question is, where do I turn from here? Send it back to GAP? Send the bolt to Gre-tan for a bushing job and custom firing pin? I could use a little advice here.

Thank, Powereng