So I am about to take the plunge. I am a very methodical person and I tend to take things slow when starting something new. I also plan to read as much as I can in order to learn. The question is do I start with a high-end press like the Dillon 1100 because of its options, or do I aim lower. I do have tons of once-fired military brass that I have been saving to eventually do this and I know the 1100 has a built in crimp removal station. I want to make accurate and consistent ammo, however, my personal and family life give me very little time. As such, I need to be able to bang out consistent and good ammo. I am from the "buy once, cry once" camp. What do you think? Am I better off with a 750 Dillon or the 1100. I plan to reload .223, .308, 6.5 CM, and maybe 9mm. Thanks for any input.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Getting into reloading- Buy the best press I can afford, or start more slowly?

- Thread starter pnorris

- Start date

Most guys I know that are into long range shooting and reloading, it is their only hobby 'for the most part' because of how time consuming it can be going to the range and being in the reloading room. I'm single with no kids, and even then it was tough shooting PRS competitions, practicing, and reloading.

I still have all of my reloading equipment but have for the most part resided to shooting factory ammo out of a SR25 when I go long these days. Maybe when I am older and retired I will get back into it, since it is a hobby even geriatrics can do.

I still have all of my reloading equipment but have for the most part resided to shooting factory ammo out of a SR25 when I go long these days. Maybe when I am older and retired I will get back into it, since it is a hobby even geriatrics can do.

@pnorris

Foremost, please find a proficient handloader who can be a mentor in the process. It will save time, money, and frustration; especially if you opt for the Dillon 1100, which can be a real challenge to set up.

I had a 1050 for a while and sold it. Changing calibers was more trouble than it’s worth for my use. I much prefer my 550 for progressive pistol rounds. I still use a single stage press for rifle ammunition, except .223 Remington.

If you like Dillon, I would encourage a 550 instead of the 1100. Easier set up, less expensive caliber changes, and much more forgiving. Pretty darned fast too.

There are a number of ways to remove crimp. Press mounted swages or power cutters. I use a swage. It’s not a ton of trouble and only has to be done once.

Bottle neck cases need trimming. Some folks set up a trimmer on their progressive press using a separate tool head. Others use power trimmers or lathes. I like a separate trimmer. Taken together, this is why I use a basic single stage press for rifle ammunition. If I were buying a new single stage press I would probably get a T7 just for ease of set up. That said, I keep looking at the Co-Ax press to replace my single stage RCBS.

Hope this helps your decision process.

Foremost, please find a proficient handloader who can be a mentor in the process. It will save time, money, and frustration; especially if you opt for the Dillon 1100, which can be a real challenge to set up.

I had a 1050 for a while and sold it. Changing calibers was more trouble than it’s worth for my use. I much prefer my 550 for progressive pistol rounds. I still use a single stage press for rifle ammunition, except .223 Remington.

If you like Dillon, I would encourage a 550 instead of the 1100. Easier set up, less expensive caliber changes, and much more forgiving. Pretty darned fast too.

There are a number of ways to remove crimp. Press mounted swages or power cutters. I use a swage. It’s not a ton of trouble and only has to be done once.

Bottle neck cases need trimming. Some folks set up a trimmer on their progressive press using a separate tool head. Others use power trimmers or lathes. I like a separate trimmer. Taken together, this is why I use a basic single stage press for rifle ammunition. If I were buying a new single stage press I would probably get a T7 just for ease of set up. That said, I keep looking at the Co-Ax press to replace my single stage RCBS.

Hope this helps your decision process.

The bold is the reason why several of my friends stopped reloading and now have Dillon 650s and other equipment just sitting. It's a bigger time sink than they realized.So I am about to take the plunge. I am a very methodical person and I tend to take things slow when starting something new. I also plan to read as much as I can in order to learn. The question is do I start with a high-end press like the Dillon 1100 because of its options, or do I aim lower. I do have tons of once-fired military brass that I have been saving to eventually do this and I know the 1100 has a built in crimp removal station. I want to make accurate and consistent ammo, however, my personal and family life give me very little time. As such, I need to be able to bang out consistent and good ammo. I am from the "buy once, cry once" camp. What do you think? Am I better off with a 750 Dillon or the 1100. I plan to reload .223, .308, 6.5 CM, and maybe 9mm. Thanks for any input.

If you don't have enough time to crank out a bunch of completed rounds in a single session, you can separate the tasks and spread them out over a course of several days or weeks. If you do that, how many stations do you really need if you're only doing 1 or 2 steps on any given session?

Example - Some sessions require doing it altogether such as powder charge, bullet seat and maybe crimp (taper/roll crimp for pistol calibers and straight wall cartridges). Sizing on the other hand is something that can be done by itself and then you can leave sized brass sitting on a shelf until you have time later to do other types of processing. Next is a matter of how efficient do you want to make several of the processes? Case feeders and bullet feeders save you time and make the process more efficient but have potential space or cost constraints.

Case feed + size/deprime = 1-3 stations (depending on how you want to do it, universal decapping die + neck bushing die + expander mandrel die? 3 stations. FLS die with decap and expander ball in? 1 station. insert whatever combo of steps you want to include).

If you don't want a case feed and only want to utilize a single FLS die to size/expand/decap, then do you need a progressive press for this task when a single stage will do just fine?

Case feed (feeding primed cases) + powder charge + powder check + bullet feed + bullet seat + taper crimp = 5 stations. If you don't need the crimp (for calibers that don't need crimping) then it's 4 stations, if you don't use powder check, it's 3. If you don't wish to spend money on certain items like a bullet feeder then the requirement is less stations.

If you do everything in one session, then you may benefit from a press with more die stations.

Last edited:

It's a much more enjoyable hobby when you are fighting with junk equipment.

Single stage you load by the box of bullets

Progressive you load by the #LBS of powder.

What people have said is sound. I also load in stages. Separate depriming (lee breechlock), tumble with some nufinish polish (shiny cases), and then size as needed, then drop and weigh powder, then load rounds and seat projectiles. Then crimp(if needed). Put in plastic zip lock bags(I like the looks at the range) then shoot.

Progressive you load by the #LBS of powder.

What people have said is sound. I also load in stages. Separate depriming (lee breechlock), tumble with some nufinish polish (shiny cases), and then size as needed, then drop and weigh powder, then load rounds and seat projectiles. Then crimp(if needed). Put in plastic zip lock bags(I like the looks at the range) then shoot.

All fantastic information. I used to load shotgun shells quite a bit. I haven’t done that in a while. Want to get my feet wet with reloading and something I plan on doing when I retire.

The time investment is something that I have to consider. The idea at the end of the day is that I can make more consistent ammo for cheaper than if I buy good ammo off the shelves. Is that a fallacy?

The time investment is something that I have to consider. The idea at the end of the day is that I can make more consistent ammo for cheaper than if I buy good ammo off the shelves. Is that a fallacy?

I think it’s accurate to say with rifle especially that you can make better & cheaper ammo than you can buy since you’re able to tune rounds for your gun. My 77 grain hand loads are definitely cheaper than what I see black

Hills listed for lol

Hills listed for lol

@pnorris

Factory ammunition can be quite good for most applications. For ICORE, I just buy factory ammunition. The cost premium isn’t much with today’s component prices and intermittent scarcity. Same for run and gun games.

Hand loading allows me to produce ammunition that I can’t buy off the shelf, tailored to my needs. For example, 9mm ammunition with heavy .358 diameter bullets to shoot in revolvers or 35 Remington ammunition for my woods walking rifle.

Factory ammunition can be quite good for most applications. For ICORE, I just buy factory ammunition. The cost premium isn’t much with today’s component prices and intermittent scarcity. Same for run and gun games.

Hand loading allows me to produce ammunition that I can’t buy off the shelf, tailored to my needs. For example, 9mm ammunition with heavy .358 diameter bullets to shoot in revolvers or 35 Remington ammunition for my woods walking rifle.

Ive been super happy with my lee pro 6000 reloading thousands of 9mm quickly.So I am about to take the plunge. I am a very methodical person and I tend to take things slow when starting something new. I also plan to read as much as I can in order to learn. The question is do I start with a high-end press like the Dillon 1100 because of its options, or do I aim lower. I do have tons of once-fired military brass that I have been saving to eventually do this and I know the 1100 has a built in crimp removal station. I want to make accurate and consistent ammo, however, my personal and family life give me very little time. As such, I need to be able to bang out consistent and good ammo. I am from the "buy once, cry once" camp. What do you think? Am I better off with a 750 Dillon or the 1100. I plan to reload .223, .308, 6.5 CM, and maybe 9mm. Thanks for any input.

I have not ran any 556 through it yet.

True, but for the OP, don’t confuse high quality ‘cheaper’ rounds with the total cost of reloading. Reloading is also a hobby, at various levels depending upon the approach. Net savings may be there if you shoot enough, but the real benefit is going to be the tuning of ammo to your rifle and needs.I think it’s accurate to say with rifle especially that you can make better & cheaper ammo than you can buy since you’re able to tune rounds for your gun. My 77 grain hand loads are definitely cheaper than what I see black

Hills listed for lol

I load .223, 9mm and .40 on 1050’s. .308 on a 550. Still keep a single stage and T7 in the corner for detail work. The 550 is capable of turning out match grade ammo in rifle calibers. It’s best feature is fast caliber changes and simplicity.

The T7 allows me to use gauges for precise measurements on how much shoulder set back for setting up the dies on other presses.

if you ever use a set of Dillon carbide dies in .308 and .223 you will be hooked. Don’t wait 30 years to try them.

The T7 allows me to use gauges for precise measurements on how much shoulder set back for setting up the dies on other presses.

if you ever use a set of Dillon carbide dies in .308 and .223 you will be hooked. Don’t wait 30 years to try them.

Be aware that the press is not the central tool of reloading, nor is it the most important, nor does it have the greatest affect on what you experience or the product you produce. Don't be press-focused.

Components like brass and bullets, and the dies have the biggest effect on the quality of the results.

There is more work to be done to the brass that does not involve the press than the work that does. The expense of the tools and equipment unrelated to the press is at least as great as the cost of the press if not considerably greater.

Components like brass and bullets, and the dies have the biggest effect on the quality of the results.

There is more work to be done to the brass that does not involve the press than the work that does. The expense of the tools and equipment unrelated to the press is at least as great as the cost of the press if not considerably greater.

When you learn to juggle, you start with one ball. Then two. Then three. Then four.

You need to learn what you're doing before trying to do them all at once. Buy a decent single stage press to learn on. You will always have a use for it. And if you end up hating handloading, you didn't dump a ton of money on a big machine.

I load 9 different calibers on 3 progressive presses.

(and about 47 others on my single stage)

You need to learn what you're doing before trying to do them all at once. Buy a decent single stage press to learn on. You will always have a use for it. And if you end up hating handloading, you didn't dump a ton of money on a big machine.

I load 9 different calibers on 3 progressive presses.

(and about 47 others on my single stage)

Last edited:

If you know you're gonna stick with it, the money isn't an issue, and you need volume.....just get an xl750 with an auto drive. If money is an issue then you'll need to prioritize things depending on actual budget.

Those who are under a time constraint and 'reload to shoot' are probably much better served with the latest and greatest equipment, as it generally reduces reloading time significantly.

Those who 'shoot to reload' and find the hobby of reloading relaxing do not need such equipment, and can save a lot of money by doing it the same way it was done 40 years before...and dare I day without sacrificing much, if anything in the accuracy department.

I'm a big fan of starting slow, and making sure you have all of the necessary ancillary equipment. You will make mistakes...and it is much less work to fix the last round you did, than it is to fix the last 5+ because you hammered away with a progressive.

Those who 'shoot to reload' and find the hobby of reloading relaxing do not need such equipment, and can save a lot of money by doing it the same way it was done 40 years before...and dare I day without sacrificing much, if anything in the accuracy department.

I'm a big fan of starting slow, and making sure you have all of the necessary ancillary equipment. You will make mistakes...and it is much less work to fix the last round you did, than it is to fix the last 5+ because you hammered away with a progressive.

I'd agree that if time is a high priority, reloading will likely conflict. I'd think about if reloading for all those cartridges is really needed. If you're only looking for increased accuracy, you likely won't see that with 9mm, and perhaps not .223 or 6.5 CM depending on your usage and what factory loads you could buy instead. Paring down cartridges could save you on considerable time changing over / setting up on progressives. I don't have a Dillon, but I'd go with whatever is easiest to change over, and perhaps a separate dedicated case prep station for primer pocket reaming (like the Lee APP).

I guess if money is not option but time is could do 2 dillion 550. One for small primer one for large primersI'd agree that if time is a high priority, reloading will likely conflict. I'd think about if reloading for all those cartridges is really needed. If you're only looking for increased accuracy, you likely won't see that with 9mm, and perhaps not .223 or 6.5 CM depending on your usage and what factory loads you could buy instead. Paring down cartridges could save you on considerable time changing over / setting up on progressives. I don't have a Dillon, but I'd go with whatever is easiest to change over, and perhaps a separate dedicated case prep station for primer pocket reaming (like the Lee APP).

Press is literally the LEAST important piece of reloading equipment. (I have 2 Prazipress so I'm not just justifying what I do - I got those just for bling, which is probably the most common reason for expensive presses, among those who grasp the fact that they dont' make better ammo.)

If you do opt to go with a reloading machine system just be aware your case prep becomes allot more important, you can run through hundreds of rounds before you realize something is wrong and have the fun of pulling allot of bullets. Right now it’s not even worth the effort to reload 9mm, with a decent fmj bullet it costs me about 21 cents to reload 9mm, and I can buy new 9mm ammo for about 24 cents shipped. The calibers I do enjoy reloading are 308, 300 win mag, 30/30, blackout, I can save a good deal of money and it will have a better bullet, but it’s not really high volume compared to 9mm and 223, so I’m happy with a single stage press, I have a hornady and a old rcbs.

If you are just starting out I strongly suggest buying a single stage press. I still have my rockchucker that I started with around 15 years ago. You need to learn how each step works and feels. When I jumped to the progressive press I made a lot of mistakes and I had reloaded for a few years prior. The progressive moves fast and makes it much harder to catch your mistake and mentally keep up with all the different stations.

Long term, progressive is the way to go if you shoot more than a box or 2 of ammo a month. And you could start with a progressive but only run 1 piece of brass through all the stations at a time until you understand and are comfortable.

Dont waste your money on the newest, baddest press unless you are just swimming in money. I’m using a hornady LNL ammo plant to load all my pistol and rifle ammo except my 7mm rem mag and 6.5prc. Only reason I don’t load those on there is I don’t want to buy the shell plate and QD die holders for guns that only burn a box or 2 a year at most.

Instead of spending money on baller presses. Use the money for items that will increase efficiently and speed such as an automatic powder dispenser/scale, and power case trimmer. The best purchases I have made for reloading are my giraurd trimmer and auto trickier/ingenuity precision setups. Much much faster. I didn’t notice any increase or decrease in precision from my rcbs powder dispenser and hand trimming but now I can crank out ammo faster than I can shoot it.

Long term, progressive is the way to go if you shoot more than a box or 2 of ammo a month. And you could start with a progressive but only run 1 piece of brass through all the stations at a time until you understand and are comfortable.

Dont waste your money on the newest, baddest press unless you are just swimming in money. I’m using a hornady LNL ammo plant to load all my pistol and rifle ammo except my 7mm rem mag and 6.5prc. Only reason I don’t load those on there is I don’t want to buy the shell plate and QD die holders for guns that only burn a box or 2 a year at most.

Instead of spending money on baller presses. Use the money for items that will increase efficiently and speed such as an automatic powder dispenser/scale, and power case trimmer. The best purchases I have made for reloading are my giraurd trimmer and auto trickier/ingenuity precision setups. Much much faster. I didn’t notice any increase or decrease in precision from my rcbs powder dispenser and hand trimming but now I can crank out ammo faster than I can shoot it.

How do you like your LNL ammo plant? I have a friend at work that was complaining about issues with the primer removal. Have you had issues with priming/depriming?If you are just starting out I strongly suggest buying a single stage press. I still have my rockchucker that I started with around 15 years ago. You need to learn how each step works and feels. When I jumped to the progressive press I made a lot of mistakes and I had reloaded for a few years prior. The progressive moves fast and makes it much harder to catch your mistake and mentally keep up with all the different stations.

Long term, progressive is the way to go if you shoot more than a box or 2 of ammo a month. And you could start with a progressive but only run 1 piece of brass through all the stations at a time until you understand and are comfortable.

Dont waste your money on the newest, baddest press unless you are just swimming in money. I’m using a hornady LNL ammo plant to load all my pistol and rifle ammo except my 7mm rem mag and 6.5prc. Only reason I don’t load those on there is I don’t want to buy the shell plate and QD die holders for guns that only burn a box or 2 a year at most.

Instead of spending money on baller presses. Use the money for items that will increase efficiently and speed such as an automatic powder dispenser/scale, and power case trimmer. The best purchases I have made for reloading are my giraurd trimmer and auto trickier/ingenuity precision setups. Much much faster. I didn’t notice any increase or decrease in precision from my rcbs powder dispenser and hand trimming but now I can crank out ammo faster than I can shoot it.

I have no issues with depriming or priming in general. Only issues I have had is when debris builds up In the primer slider. It’s a quick fix, just blow it out with some compressed are every once in a while.How do you like your LNL ammo plant? I have a friend at work that was complaining about issues with the primer removal. Have you had issues with priming/depriming?

I really like my press and have no reason to look for an upgrade.

Buy the best you can, reloading stuff doesn't often wear out so its usually getting upgraded just because.

A couple years ago when I started de-priming and running a mandrel in a separate step I went to a Dillon 750 and it 100% saves me a lot of time.

I manage to load enough to shoot for fun/ practice and run about 3 matches a year, I've got a family and a bunch of other hobbies, some of those hobbies have taken a hit but that's what having a family is about.

A couple years ago when I started de-priming and running a mandrel in a separate step I went to a Dillon 750 and it 100% saves me a lot of time.

I manage to load enough to shoot for fun/ practice and run about 3 matches a year, I've got a family and a bunch of other hobbies, some of those hobbies have taken a hit but that's what having a family is about.

In my opinion you can make the best ammo on a Rockchucker or a T7. Everything else just makes it faster but I don’t see a quality increase past that.

I also suggest the rockchucker. I have one my dad used in like the 80s. Not the newest and greatest, but it turns out accurate ammo.

Might be advantageous being slow when you start out. Instead of screwing up 100 pieces of brass before you realize it, maybe you’ll only screw up 10.

Might be advantageous being slow when you start out. Instead of screwing up 100 pieces of brass before you realize it, maybe you’ll only screw up 10.

Agreed but if you just want a wicked looking press that’s fine too. If you don’t buy the one you want off the hop you’ll likely end up buying something fancier down the road. (Area 419, Prazzi)In my opinion you can make the best ammo on a Rockchucker or a T7. Everything else just makes it faster but I don’t see a quality increase past that.

When I got in I bought a 550. I still have it tens of thousands of rounds later. I use it more less as a convenient single stage as much as a true progressive where I'm clanging and banging out 1k 9mm or 223 rounds at a time. Sometimes I wish it was a 750, and may get one at some point but then sometimes I'm glad its not. Such as when Im using it as a single stage Im glad it doesnt auto index. 550 has done everything I want it to do and Id absolutely steer you in that direction starting out. Loading 9mm and anything really on a single stage BLOWS. Using the 550 as a single stage while doing precision ammo, the dies stay set up on the toolhead. I was gifted an old rock chucker and the only use I have for it is as a dedicated de capping station, which I rarely do on its own but should. It may be an ignorance is bliss thing that I dont find myself lusting for a fifth station. I probably dont do enough bulk (1k+) loading that Im wishing for a case or bullet feeder. If I was wanting to do more bulk Id probably say get the 750. Ive heard the 1050/1100 is a different animal and haven't played with one so I cant say do or dont.

Using the upgrades from Creedmoor Sports with the CNC cut SS turrents does move the T7 up a notch. When you are getting no noticeable run out along with very consistent low SDs I can’t justify upgrading, though having the CNC SS turrent for each cartridge puts you in the same price range of the 419 zero. But I would have to share turrents with other cartridges. Do all the dies that work in a T7 work in a zero? Thanks…In my opinion you can make the best ammo on a Rockchucker or a T7. Everything else just makes it faster but I don’t see a quality increase past that.

I also have the Zero. The dies are all interchangeable unless you’re getting the head for the big dies on the Zero. At that point you’ve made a specific choice anyway.

And to the other above, I did exactly as you described. Rock Chucker-T7- then the Zero. I really really like my Zero but I don’t recommend it unless people are looking for that class of press.

And to the other above, I did exactly as you described. Rock Chucker-T7- then the Zero. I really really like my Zero but I don’t recommend it unless people are looking for that class of press.

I enjoy well made equipment, but have gotten to where if I can’t see a difference on target I leave it alone. With the upgrades & 5 new SS turrents I could have paid for the zero. I think it must be a pleasure to work with. If I wasn’t so old & targets looking good I’m sure I would have one. Some of these improvements are such beautiful machinery work they are like a piece of art. One beautiful piece of equipment that earns its keep is SACs top barrel vise. I use to occasionally put a cosmetic scratch on the random barrel. In two years not a single scratch. I even used the same piece of painters tape 7 times in a row without changing it.I also have the Zero. The dies are all interchangeable unless you’re getting the head for the big dies on the Zero. At that point you’ve made a specific choice anyway.

And to the other above, I did exactly as you described. Rock Chucker-T7- then the Zero. I really really like my Zero but I don’t recommend it unless people are looking for that class of press.

Congrats on the Zero!

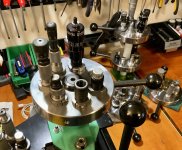

Attachments

Even with the Zero the T-7 stays full and used regularly for 260 Remington and 45 Colt.

This is the 1st time I have seen them side to side. What a different perspective! It’s a smooth gentle beast. How much are extra turrents? This is really a pic that changes my perspective. It’s absolutely awesome. I can’t afford it, but I think everyone would have one if they could. I never thought I would see these kind of changes. I starting early to mid seventies. There wasn’t an internet then. About 5-10 years later I gave reloading a break to raise my children. I’ve been back at it and seeing some awesome tool & knowledge advancement!. Congratulations & thanks again for those pics. My pics are 1 the T7 & the other is looking out the window in my reloading room. You’ll have a good night, Lynn.

Attachments

Similar threads

- Replies

- 26

- Views

- 1K

- Replies

- 21

- Views

- 429

- Replies

- 69

- Views

- 2K