I’ll be honest, I was turned away from SLA printing when I found out how brittle the materials were and have gotten lost in the world of FDM. Looks like I have some research to do and get my SLA printer fired back up. What resin should I look into?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gun related 3d printer files

- Thread starter 702lineman

- Start date

An interesting article concerning the strength of SLA models.

all3dp.com

all3dp.com

SLA Resin Strength: How Strong Is 3D Printed Resin? | All3DP

SLA resin prints aren't famous for their strength. Yet, you might be surprised at how they compare to other materials...

I’ll be honest, I was turned away from SLA printing when I found out how brittle the materials were and have gotten lost in the world of FDM. Looks like I have some research to do and get my SLA printer fired back up. What resin should I look into?

I use 3/4 PRUSA Tough Resin and 1/4 Siraya Blu. Takes away all the brittleness. Actually I've used the Blu with many different resins as an additive. Works well. I've never had really good luck with the strength between layers with FMD models. I've got a lot of functional models made with my FMD printer, but none that I would recommend for use on a firearm.

One other bit of advice, keep in mind the shrinkage of PLA models once they are cured.

Last edited:

Very interesting read! I must say, you have intrigued me and will be giving the SLA Printer a second chance.

Good luck!

I'm going to have to give the parallax nob a trySome of the useful stuff I’ve done with my 3D printer or other DIY:

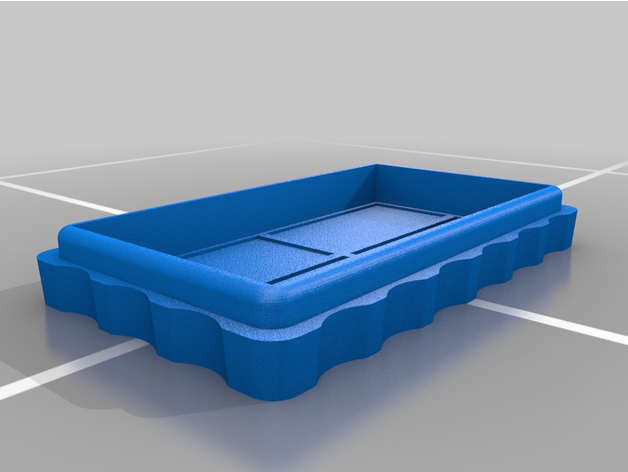

Pelican 1040 .22 LR ammo insert for Lapua/SK/Wolf racks

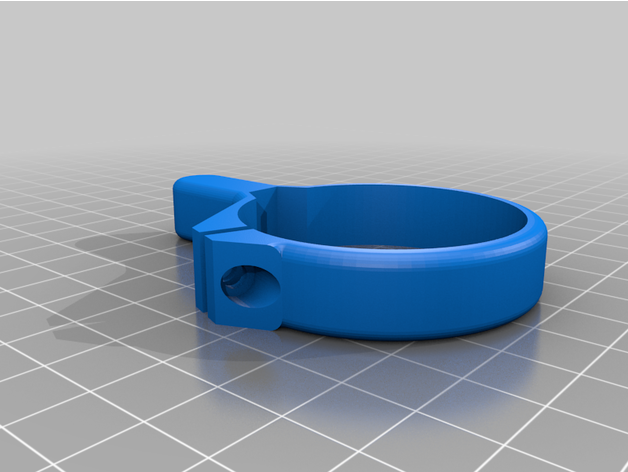

View attachment 7328874

Modified Amazon arca clamp to a 2-bolt attachment

View attachment 7328876

Ruger BX-1 2 magazine + 200 rds.22 LR Pelican 1060 insert

View attachment 7328885

View attachment 7328886

Vudoo magazine flag block with Logo

View attachment 7328889

MDT ACC bag rider

View attachment 7328891

View attachment 7328892

Vudoo Mag extension

View attachment 7328895

Tikka T1x Extended Mag release

View attachment 7328903

100 rd. .22 LR ammo insert for Agency Arms barrel case

View attachment 7328905

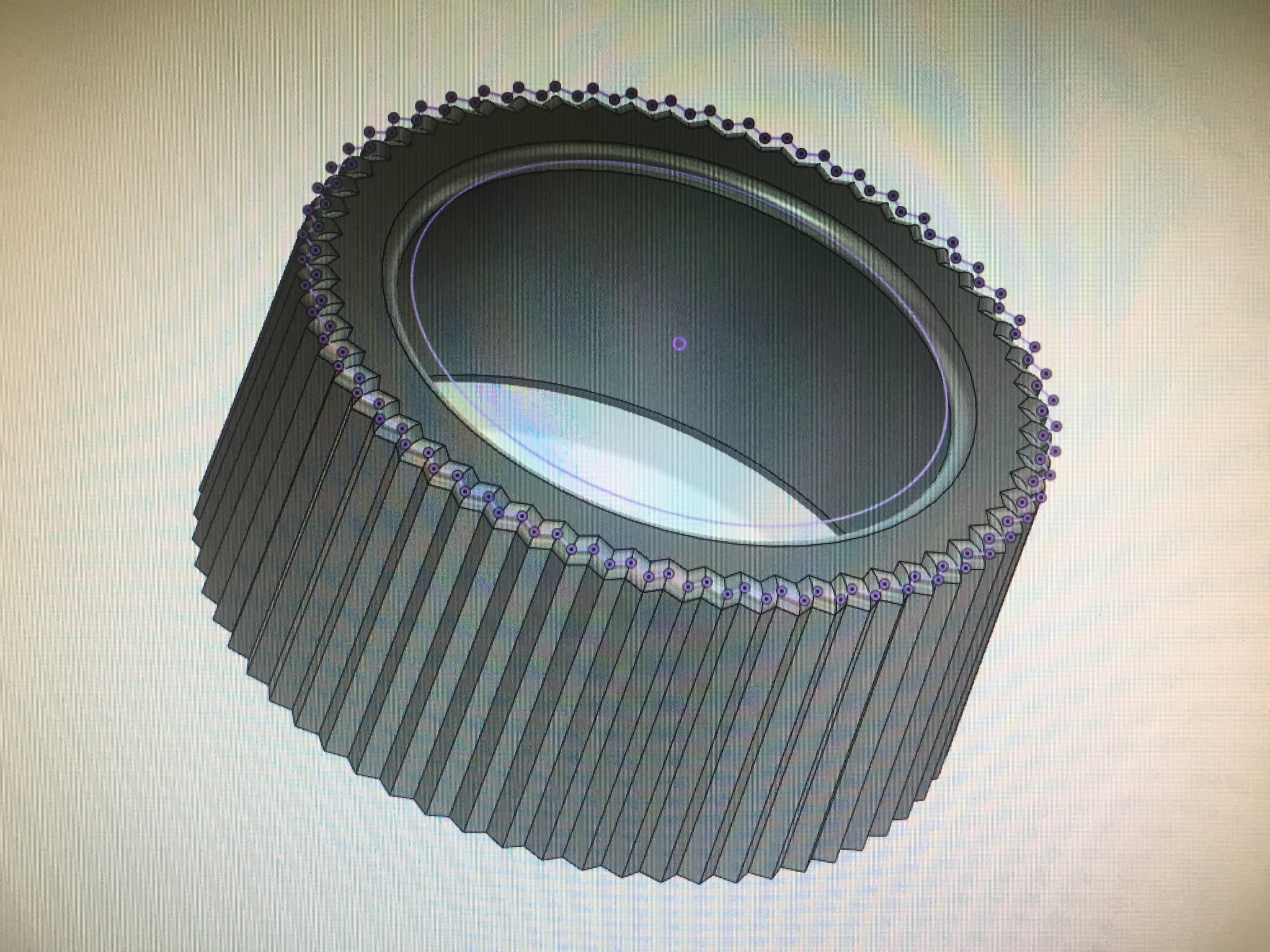

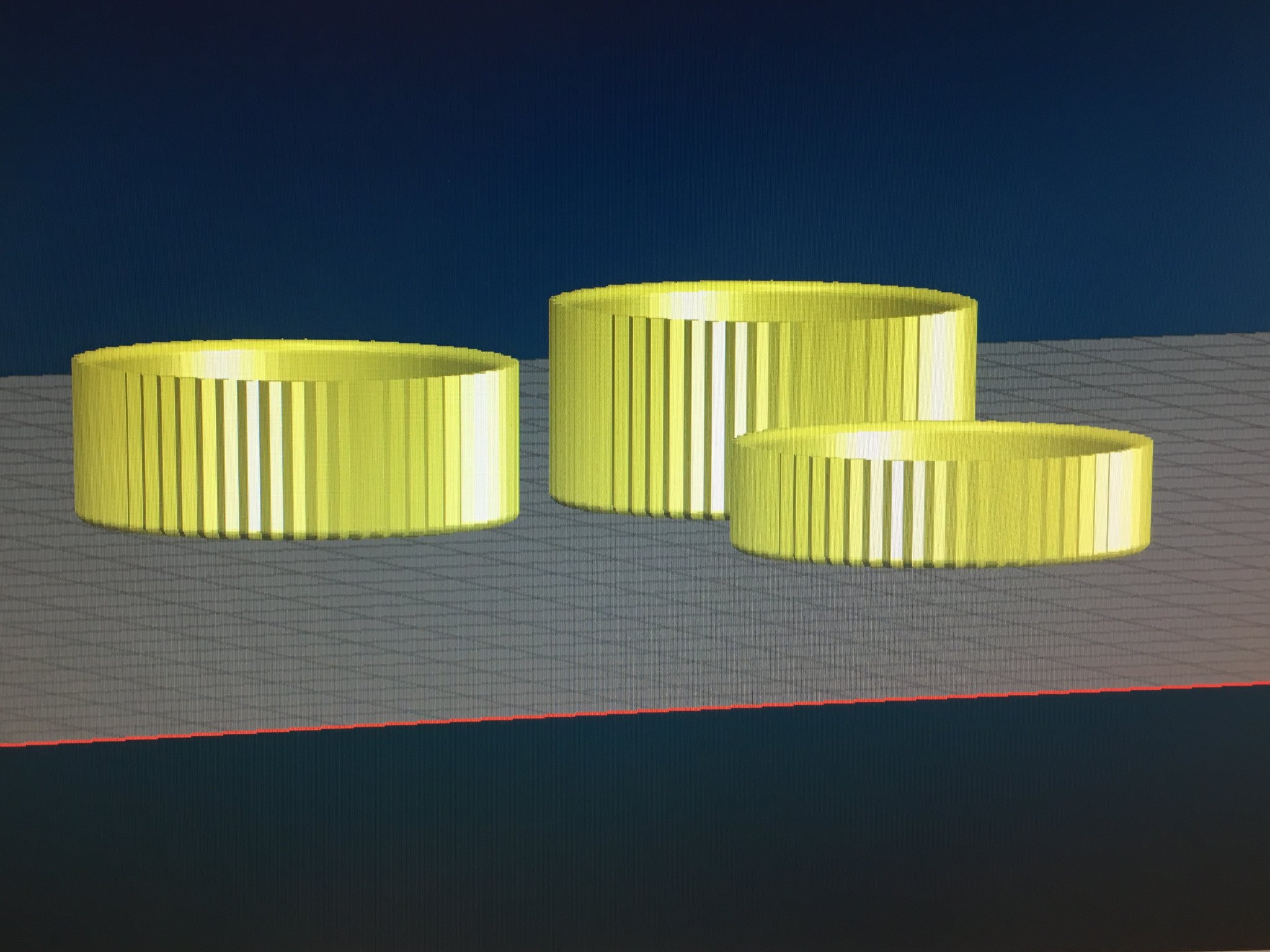

Athlon Ares BTR Parallax Knob Wheel

View attachment 7328914

View attachment 7328915View attachment 7328920

CZ 455/457 +3 mag extension

View attachment 7328916View attachment 7328917

MDT ACC/Tikka T1x Mag Sleeve

View attachment 7328918View attachment 7328919

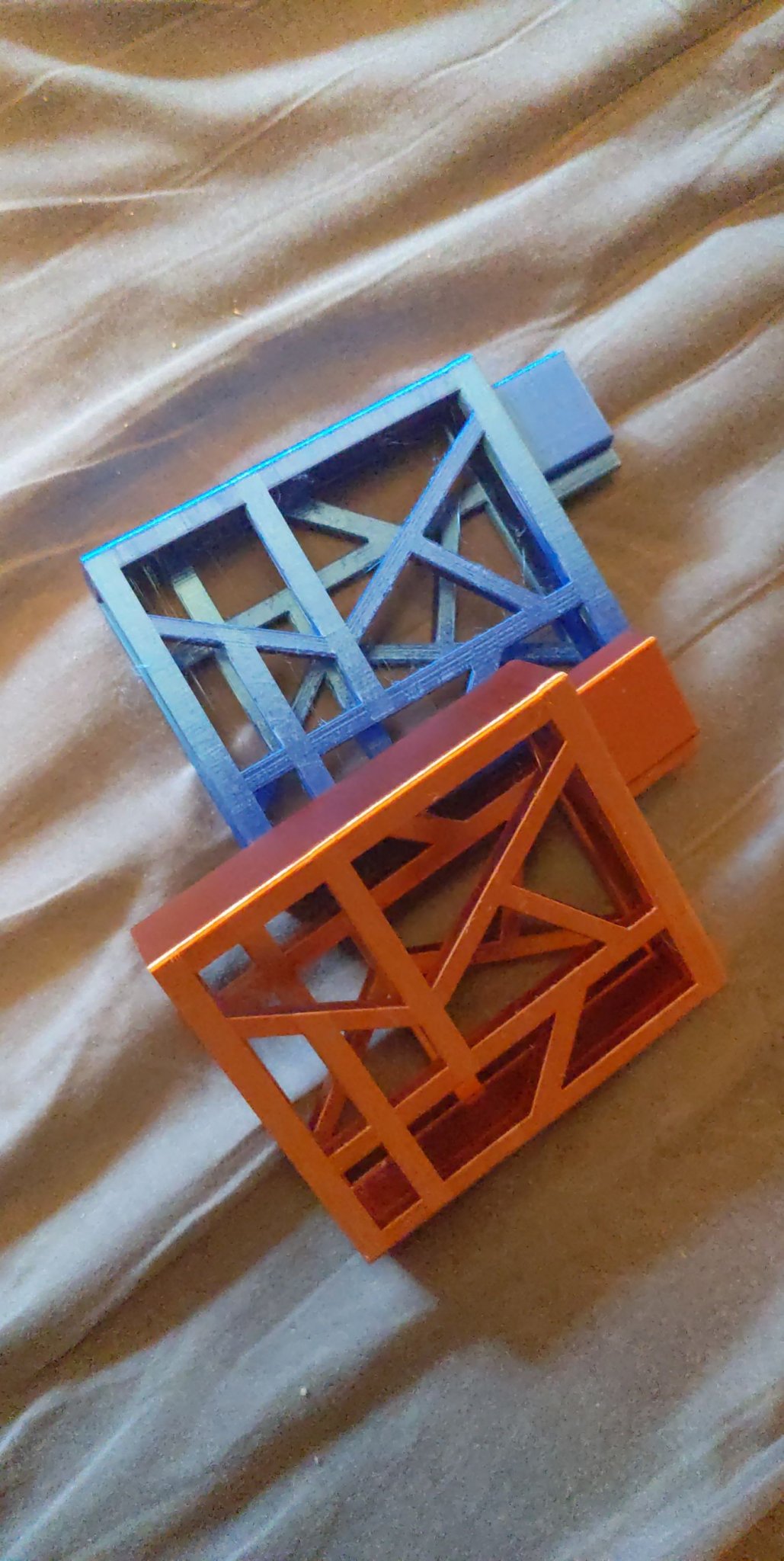

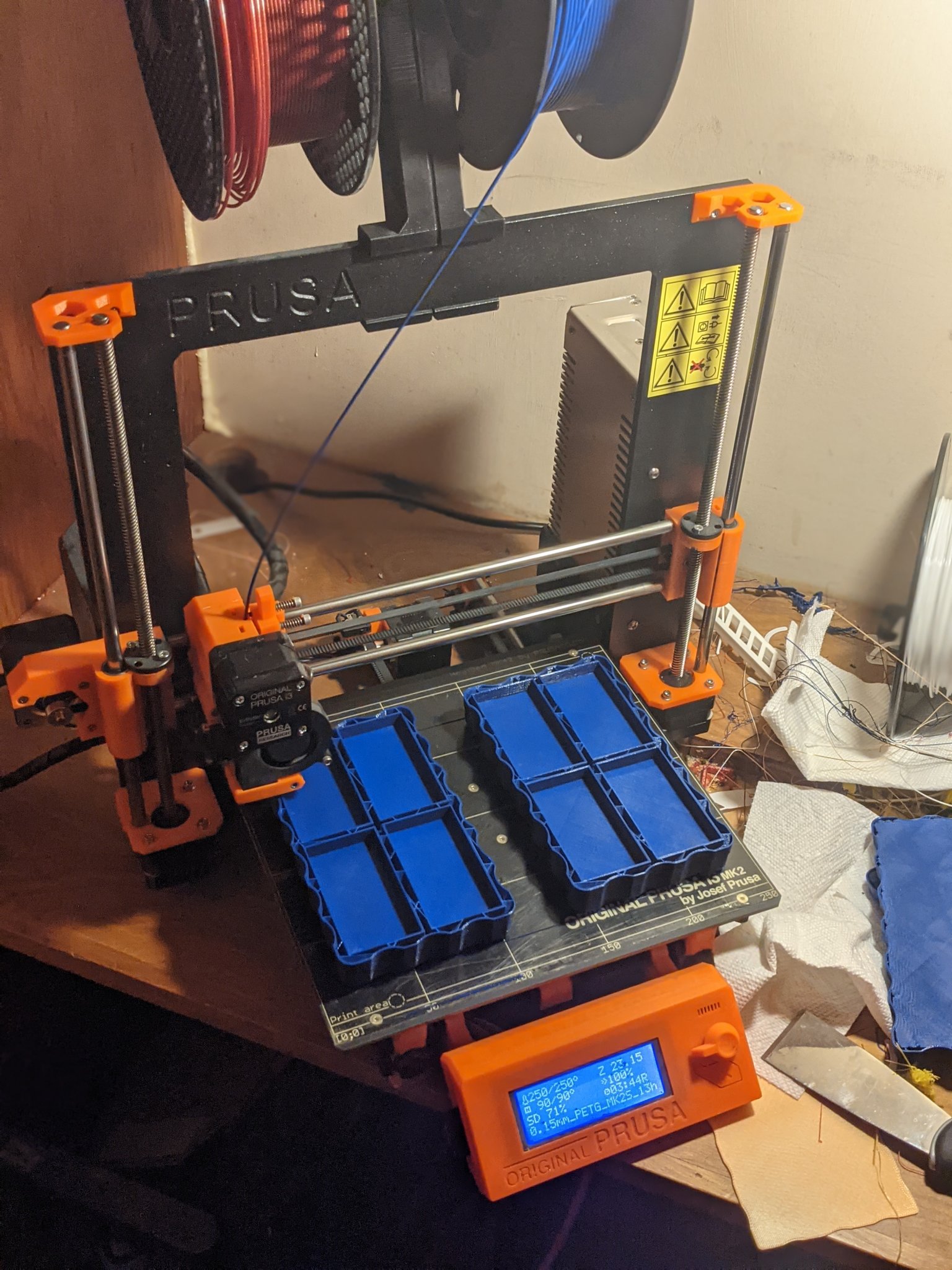

My 3D printed Vudoo/AICS Mag blocks are available again. New design that doesn't interfere with the Vudoo extraction hooks.

I'm also doing an insert for the pelican 1040 case to hold 200 rounds of 22LR. The stock case is designed around the Lapua / SK ammo racks, but I can modify it for other types if needed.

I have some pre-printed inserts available.

Ifyou want your name or customized text in it I would have to print those to order.

Colors currently available are gold, copper, silver, transparent red, solid red, navy blue, silk blue, silk Orange, and matte black. I only have a couple of each color pre-printed, if the color isn't available I can print more.

I'm also doing an insert for the pelican 1040 case to hold 200 rounds of 22LR. The stock case is designed around the Lapua / SK ammo racks, but I can modify it for other types if needed.

I have some pre-printed inserts available.

Ifyou want your name or customized text in it I would have to print those to order.

Colors currently available are gold, copper, silver, transparent red, solid red, navy blue, silk blue, silk Orange, and matte black. I only have a couple of each color pre-printed, if the color isn't available I can print more.

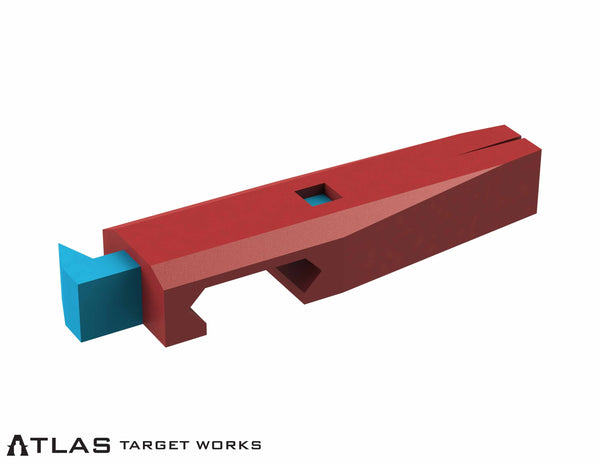

3D Printed Rimfire AICS Mag/Chamber Block (Vudoo, Bergara etc...)

1/8" Elastic Rope retains the open bolt to keep it from flopping around I print this with 3 wall layers and top/bottom and 20% infill If you print it yourself, print in the same orientation as seen in the product image Don't leave in direct sunlight in your vehicle or other hot areas. They're...

3D Printed Dope Card Holder - Printer File (.STL)

I print this with 2mm walls and top/bottom and 20% infill Print the card holder with the open end on the print bed Print the keeper with the completely flat side on the print bed

3D Printed RCBS Ram Primer Slot Block - Printer File (.STL)

After printing this improved primer catcher from over on Thingiverse.com I needed something to block slot for the priming tool. This little part keeps the primers from falling out the wrong side of the ram making sure that they end up in your primer catcher and not on the floor. I print this...

3D Printed T-Post Mount - Printer File (.STL)

If you like shooting steel with .308 or smaller and are looking for a project for your 3D printer this T-Post Mount might just be for you. You've still got to pickup some chain or our rubber straps and a carabener but all in all you can get into a mount pretty cheap. We don't have any long term...

3D Printed T-Post Wind Flag Mount - Printer File (.STL)

If you're a cheater like me and want an easy way to help read the wind then this little doohicky is for you. It easil mounts to a T-Post to hold a wind flag. Check out the video below for details on how to set it up.

Here is another article. With the proper paperwork this would be an interesting project.I’ll be honest, I was turned away from SLA printing when I found out how brittle the materials were and have gotten lost in the world of FDM. Looks like I have some research to do and get my SLA printer fired back up. What resin should I look into?

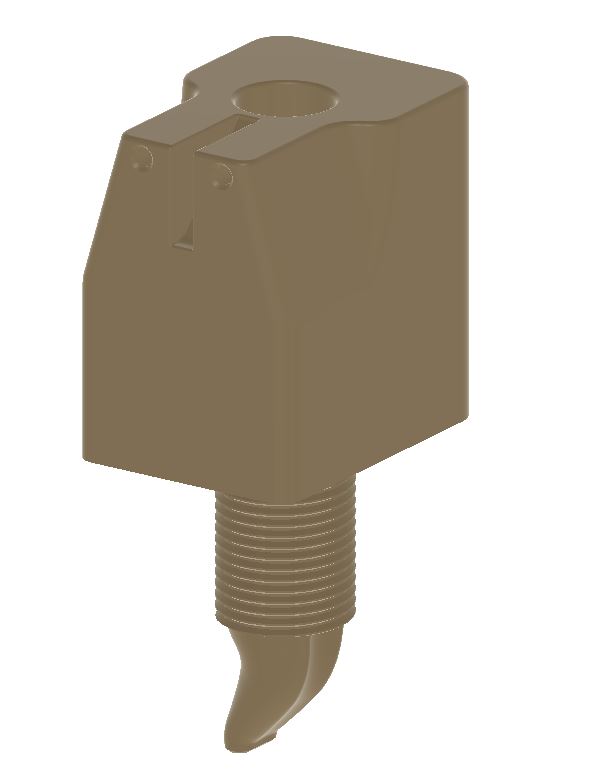

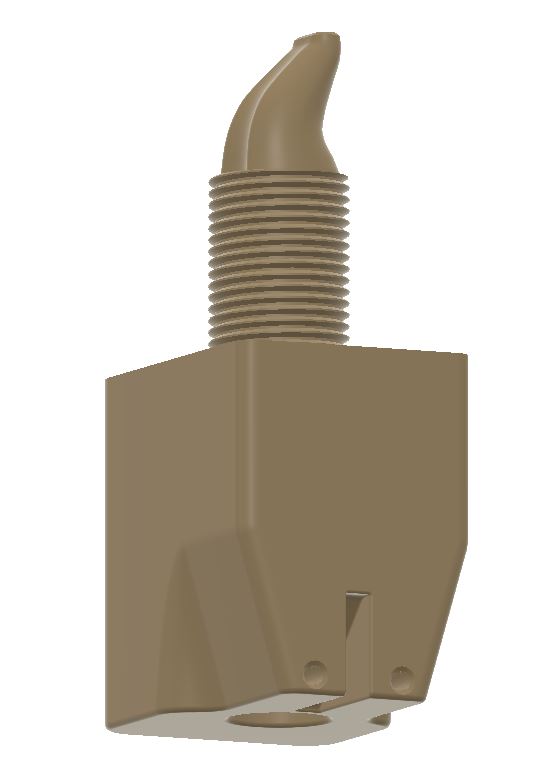

Man Makes Silencer with 3D Printer

Read: Man Makes Silencer with 3D Printer from Dave Merrill on December 11, 2024 for Recoil.

www.recoilweb.com

Same results I have achieved printing 22 suppressors out of PETG, around a 50 rnd life. 3D printing is an easy way to proof out internal geometry before going all out with machined parts for testing. The fact that all the nessaccery ATF identification can be printed right on the part instead of having to engrave the tube separately is a bonus. And yes, I am Class 3 SOT

So wondering is one of you guys could print a bullet holder insert for the harbor freight apache cases the 1800 and 2800. Would life to see with a 3D printer insert how many rounds you could get in there. If it was reasonably priced I would be in for a few for sure

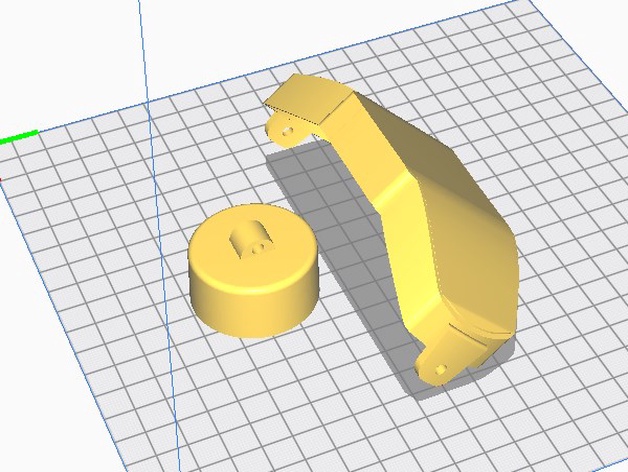

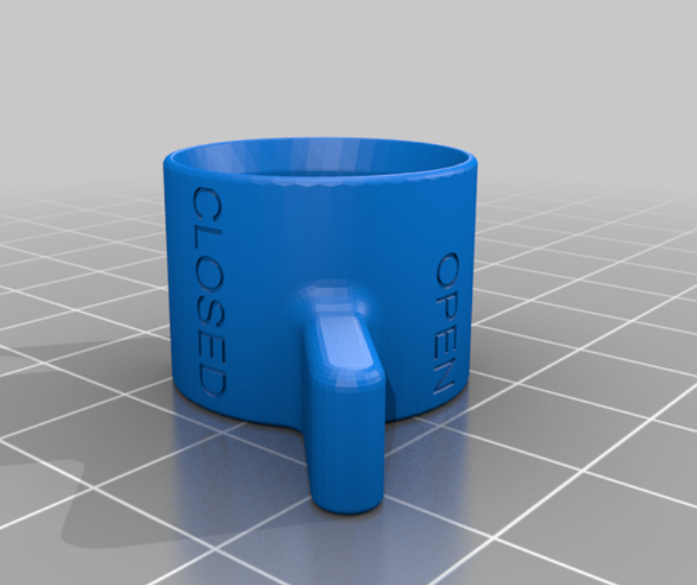

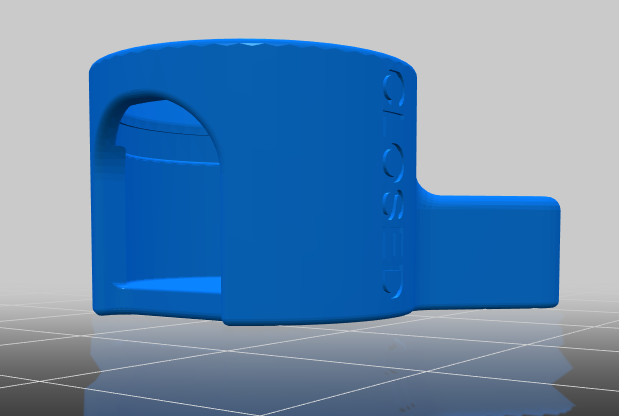

Anyone with a Frankford Arsenal Intellidropper will benefit from one of these, it's a replacement powder dump tube tap with a lever to grab hold of and open and closed indicators. You just pop the original off and push this one on. I've uploaded it to Thingiverse here: https://www.thingiverse.com/thing:4736792

That has to be the best upgrade for the FA. Can't count the times I forgot it was open.Anyone with a Frankford Arsenal Intellidropper will benefit from one of these, it's a replacement powder dump tube tap with a lever to grab hold of and open and closed indicators. You just pop the original off and push this one on. I've uploaded it to Thingiverse here: https://www.thingiverse.com/thing:4736792

View attachment 7538015 View attachment 7538017

I've only used it twice and left it open after the first time. Next job is some solid extended feet so I can fit something under it to drain the powder without having to move it and re-level it.That has to be the best upgrade for the FA. Can't count the times I forgot it was open.

Awesome thread! I do a ton of printing (and selling of gun related prints) but won't like my site here. I will link an article to a 3D printed CZ scorpion though. Currently working on printing all the parts for it, pretty pumped. All the files are available online.

AWCY's Hybrid 3D Printed Scorpion EVO - The Kommando Blog

AWCY's Hybrid 3D Printed Scorpion EVO - The Kommando Blog

Has anyone tested any ar parts besides the lower? For instance; gas block, muzzle brake, hand guard, ect.?

I'm printing a pistol blade stabilizer as I type this for grins. Wondering what other parts people have printed and how long they held up.

I'm printing a pistol blade stabilizer as I type this for grins. Wondering what other parts people have printed and how long they held up.

Has anyone tested any ar parts besides the lower? For instance; gas block, muzzle brake, hand guard, ect.?

I'm printing a pistol blade stabilizer as I type this for grins. Wondering what other parts people have printed and how long they held up.

I would never consider a gas block or a muzzle brake with hobbyist type 3d printers. My son has a printer that prints stuff that goes on Space X rockets, but you or I would never be able to afford one of them.

Are you printing metal or polymer? Can't imagine a polymer anything that sees pressure or heat (gas block, muzzle brake, etc)Has anyone tested any ar parts besides the lower? For instance; gas block, muzzle brake, hand guard, ect.?

I'm printing a pistol blade stabilizer as I type this for grins. Wondering what other parts people have printed and how long they held up.

What do you mean by cleats? Like claw feet?How about some cleats that fit an atlas bipod?

Unless they were printed in metal I don't think that would hold

Maybe not for people that abuse it. Its not an intricate fragile part. Worth a shot, they want almost $80 for a set.Unless they were printed in metal I don't think that would hold

Attachments

It’s not particularly intricate but it is a loadbearing part. 3-D printed plastic will not hold up in that position. Even the nylon and carbon fiber filament mixtures Would have difficulty with the part that was that directly loadbearing bearing

How much load is it really bearing?It’s not particularly intricate but it is a loadbearing part. 3-D printed plastic will not hold up in that position. Even the nylon and carbon fiber filament mixtures Would have difficulty with the part that was that directly loadbearing bearing

Well, depends on the rifle and the shooting position, but the weight of the rifle and a portion of your body weight.How much load is it really bearing?

I measure these things by the investment in the part in relation to it's inevitable failure. At the end of the day, you'll have 10-15 minutes of design work and $2 worth of polymer into it so why not? The difficulty would be the detent ball, which I would replace with a press fit pin to keep them from rotating.Well, depends on the rifle and the shooting position, but the weight of the rifle and a portion of your body weight.

10 to 15 minutes of design work is... optimistic. But it lasted you more than a day of actual field use, I’d be surprised.I measure these things by the investment in the part in relation to it's inevitable failure. At the end of the day, you'll have 10-15 minutes of design work and $2 worth of polymer into it so why not? The difficulty would be the detent ball, which I would replace with a press fit pin to keep them from rotating.

I can get it to you in a few hours.What's the height and diameter of the internal mounting portion?

This might come in handy for anyone with an autotrickler without the autothrow. It's a mount for a Lee perfect powder measure to the A&D lid.

https://www.thingiverse.com/thing:4762745

https://www.thingiverse.com/thing:4762745

10 to 15 minutes is realistic. For people that know what they're doing in CAD it doesn't take long. If I had the necessary dimensions its literally 5 minutes or less...10 to 15 minutes of design work is... optimistic. But it lasted you more than a day of actual field use, I’d be surprised.

You could make these last a while with the proper print orientation and printing parameters. Will the last a lifetime like steel ones? No. But no one is expecting them to.

Did you ever get this? Thought I could draw an option up.I can get it to you in a few hours.

Yeah, he pm'ed me. .4895 diameter .6 high, .090 detent centered at .4 high is what I have.Did you ever get this? Thought I could draw an option up.

Late to the party but this is the one I use the most. Load it in Fusion360 and customize to whatever you want/need for your specific scope.Anyone print a throw lever for a Vortex? Wonder if it would even be strong enough with out making it really big.

Customizable Scope Throw Lever by mvasilakis

Someone mentioned an issue they had with my last throw lever design. ( https://www.thingiverse.com/thing:3080614 ) The lever hit their bolt so to cycle a round they would need to mess with the scope. Not ideal. It got me thinking and as I learned Fusion360 (Last model was made in Rhino) I...

Pelican 1040, 22LR Ammo Storage by A-bear

Work on the beta testing is completed. You can see in the final design in the photos. The tray does not sit on the bottom of the case, leaving a little run to store the empty (flat folded) ammo cartons. The tray was designed for use with the solid cover 1040 or 1050... On the solid cover...

Wanted to protect the turret caps on this M40A5's S&B. Simple and easy.

Also Made some stackable cheek piece spacers. This prevents loosing cheek height when the screws eventually come loose and makes cheek height repeatable when you take it off for cleaning.

Also Made some stackable cheek piece spacers. This prevents loosing cheek height when the screws eventually come loose and makes cheek height repeatable when you take it off for cleaning.

Willing to share the CAD file for the spacers?Wanted to protect the turret caps on this M40A5's S&B. Simple and easy.

View attachment 7587838

View attachment 7587839

View attachment 7587840

View attachment 7587841

Also Made some stackable cheek piece spacers. This prevents loosing cheek height when the screws eventually come loose and makes cheek height repeatable when you take it off for cleaning.

View attachment 7587842

View attachment 7587843

View attachment 7587845

Absolutely! I actually have extras. If you want, you can DM me your info and I'll send you what I got. It's 6 stacks and 4 of the thin shims. For reference, I only used 4 stacks and 4 shims. So that should give you over an 1" of cheek rise. If not, I can try to send the file. I've never actually tried to send one of these files. Would that be through email? And would you need the .stl or Gcode file? Either way I'll give it a try.Willing to share the CAD file for the spacers?

Awesome, will send you a PM.Absolutely! I actually have extras. If you want, you can DM me your info and I'll send you what I got. It's 6 stacks and 4 of the thin shims. For reference, I only used 4 stacks and 4 shims. So that should give you over an 1" of cheek rise. If not, I can try to send the file. I've never actually tried to send one of these files. Would that be through email? And would you need the .stl or Gcode file? Either way I'll give it a try.

View attachment 7590731

View attachment 7590732

Similar threads

- Replies

- 21

- Views

- 646