Inletting stocks is something I've done now for 20 or so years. Initially on a 1940's era Bridgeport knee mill. Thankfully, we've been able to usher this process from the dark ages into something a bit more present day.

Here's how it all starts. A receiver, a surface plate, a height stand, some gauges, and a CAM system.

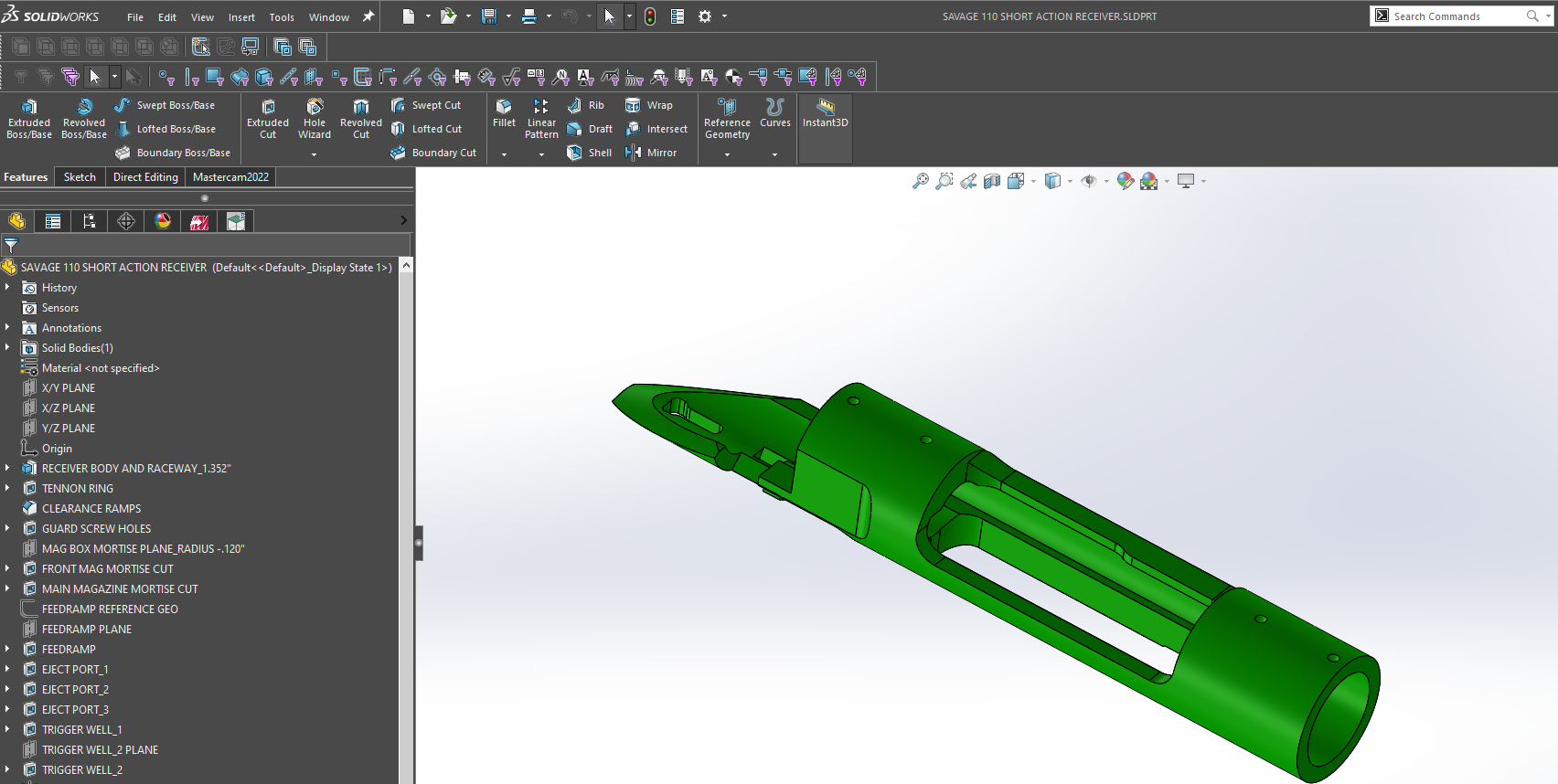

Model created:

From here I export it as a STEP file and dump it into the lap of the stock dept. Shayne will then use it to generate tool paths to chew on a stock.

Example: (not a Savage, but the process is basically the same) This is an older clip from almost 10 years ago, but it illustrates the process pretty well. Equipment and software has been updated significantly. The machine shown is a 1991 production Haas VF1. -basically, the machine Noah used to engrave the 10 commandments. I donated it to the local high school in 2016 when we replaced it. Still going today, lol.

Here's how it all starts. A receiver, a surface plate, a height stand, some gauges, and a CAM system.

Model created:

From here I export it as a STEP file and dump it into the lap of the stock dept. Shayne will then use it to generate tool paths to chew on a stock.

Example: (not a Savage, but the process is basically the same) This is an older clip from almost 10 years ago, but it illustrates the process pretty well. Equipment and software has been updated significantly. The machine shown is a 1991 production Haas VF1. -basically, the machine Noah used to engrave the 10 commandments. I donated it to the local high school in 2016 when we replaced it. Still going today, lol.