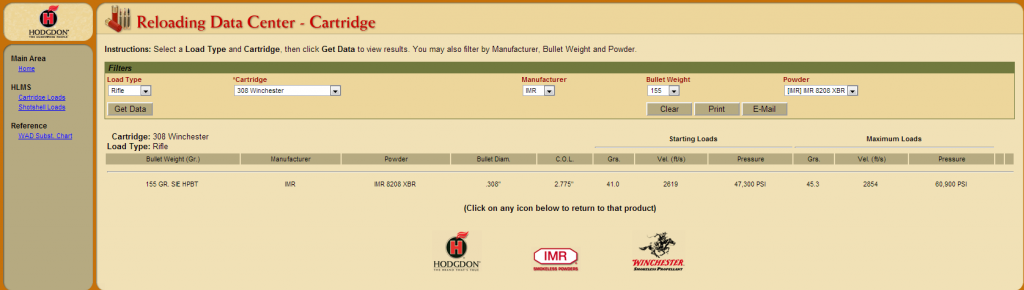

I loaded some .308 last week for a range trip with 155 Nosler Custom Comps over 48.0 gr. of 8208XBR which is 1.0 gr under max according to Hodgdon's Annual Manual. I got 3 blown primers in a row, so I quit shooting and pulled all the loads. Today I was shooting 45.0 gr. of 8208XBR and, although I am getting primer strikes, the primers are not detonating. I think I may have broken or damaged my firing pin. Has anyone ever replaced a firing pin in a Savage bolt?

Last edited: