To me, what doesn't add up logically about using solvent is the question of whether or not its a lubricant or a stripper of lubricant. How does it make sense to end the barrel cleaning process using solvent and not with oiling the barrel? The different solvent manufacturers imply that it cleans and lubricates. Then what is the point of the bore guide? I thought this was so you don't strip lubricant in the receiver area. I noticed that bore tech eliminator doesn't evaporate and remains oily to the touch. So why do I need a bore guide? Why do I need to keep a lubricant out of the receiver?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

is solvent a lubricant? then why the bore guide?

- Thread starter Walter Haas

- Start date

The bore guide is so the cleaning rod makes minimal contact with the rifling. You want the patch/brush in the rifling but not the rod. This is obviously much more important with steel rods. Whatever solvent, oil, CLP, etc. WILL get into the receiver/breach and that’s perfectly fine unless you’re gobbing it on.

Lubricant? Oh no, I've always seen them marketed as two different substances - always ending with a very light oil coat on almost all instructions that I've read. Solvent is strictly for copper/powder residue (or lead in some cases).

The bore guide is not only to (try to) keep stuff out of the receiver and trigger group, but more importantly so the jag and rod are centerline with the bore, keeping them both from thrashing the throat/rifling.

The bore guide is not only to (try to) keep stuff out of the receiver and trigger group, but more importantly so the jag and rod are centerline with the bore, keeping them both from thrashing the throat/rifling.

That makes sense. The Bore Tech Eliminator stuff is definitely oily feeling, though. The only oil I have is FP10. Should I finish with that, then? I don't want to f*^k up my new rifle. I didn't like pushing that bronze brush through. Knowing me I've probably already scratched the sh*t out of my barrel already, and I've only fired 8 rounds since I bought it!Lubricant? Oh no, I've always seen them marketed as two different substances - always ending with a very light oil coat on almost all instructions that I've read. Solvent is strictly for copper/powder residue (or lead in some cases).

The bore guide is not only to (try to) keep stuff out of the receiver and trigger group, but more importantly so the jag and rod are centerline with the bore, keeping them both from thrashing the throat/rifling.

Yes, what they said.

Bore guide simply guides the rod down the middle of the bore to not drag it unevenly over one side of the lands.

The seal at the chamber end is just a nice luxury to help center and retain the guide in the aciton with the added benefit of keeping all the fluid going down the barrel instead of back into your action where it will only serve to get messy.

The lubrication etc isnt like it leaves a specific oil or grease per say, some chemicals can strip every last bit of everything out leaving dryass unprotected metal that more prone to easy rust etc, the "lubrication" sales pitch just lets you know that you dont have to give it an additional specific oiling to keep it from rusting in the safe.

Just wipe the eliminator out until the patches come out dry and arent sopping wet blue and black and youll be fine.

Bore guide simply guides the rod down the middle of the bore to not drag it unevenly over one side of the lands.

The seal at the chamber end is just a nice luxury to help center and retain the guide in the aciton with the added benefit of keeping all the fluid going down the barrel instead of back into your action where it will only serve to get messy.

The lubrication etc isnt like it leaves a specific oil or grease per say, some chemicals can strip every last bit of everything out leaving dryass unprotected metal that more prone to easy rust etc, the "lubrication" sales pitch just lets you know that you dont have to give it an additional specific oiling to keep it from rusting in the safe.

Just wipe the eliminator out until the patches come out dry and arent sopping wet blue and black and youll be fine.

Barrel steel hardness > bronze brush. You would wear your arm out and multiple brushes before you ever scratched the barrel with a bronze brush. The rod is more dangerous than the bronze brush on the end. Like others have mentioned. Bore guide is to keep your rod centered and not dinging up your throat/lands.

I tend to not use a brush at all unless i'm really struggling to get a carbon ring off and only clean the barrel when accuracy starts to drops off. Seems to be about 450 rnds on my 6.5 that I notice the accuracy drop off.

I tend to not use a brush at all unless i'm really struggling to get a carbon ring off and only clean the barrel when accuracy starts to drops off. Seems to be about 450 rnds on my 6.5 that I notice the accuracy drop off.

Yes, what they said.

Bore guide simply guides the rod down the middle of the bore to not drag it unevenly over one side of the lands.

The seal at the chamber end is just a nice luxury to help center and retain the guide in the aciton with the added benefit of keeping all the fluid going down the barrel instead of back into your action where it will only serve to get messy.

The lubrication etc isnt like it leaves a specific oil or grease per say, some chemicals can strip every last bit of everything out leaving dryass unprotected metal that more prone to easy rust etc, the "lubrication" sales pitch just lets you know that you dont have to give it an additional specific oiling to keep it from rusting in the safe.

Just wipe the eliminator out until the patches come out dry and arent sopping wet blue and black and youll be fine.

Barrel steel hardness > bronze brush. You would wear your arm out and multiple brushes before you ever scratched the barrel with a bronze brush. The rod is more dangerous than the bronze brush on the end. Like others have mentioned. Bore guide is to keep your rod centered and not dinging up your throat/lands.

I tend to not use a brush at all unless i'm really struggling to get a carbon ring off.

Yes, and yes...

That makes sense. The Bore Tech Eliminator stuff is definitely oily feeling, though. The only oil I have is FP10. Should I finish with that, then? I don't want to f*^k up my new rifle. I didn't like pushing that bronze brush through. Knowing me I've probably already scratched the sh*t out of my barrel already, and I've only fired 8 rounds since I bought it!

Consider the oil a neutralizing agent at the end.

Run a bore guide, only push patches/brushes from the chamber to the muzzle and you'll be fine. Clean the crown with a wooden dowel and green Scotch-Brite, good to go.

The patches are another problem. I read that my J Dewey rod can be very tight for some barrels, and when I tried to put a circular cloth patch with solvent in it hardly even wanted to go into the bore guide and then was taking a lot of force without going into the barrel after the throat. It got stuck entering the barrel. I still don't know if I needed more force, I was probably pushing 10 or 12 lbs on the rod, so I backed off and luckily the patch pulled away when I pulled the bore guide out. So I don't know if something's wrong or not.Yes, and yes...

Consider the oil a neutralizing agent at the end.

Run a bore guide, only push patches/brushes from the chamber to the muzzle and you'll be fine.

Do I need more force is or something wrong? You can't tell how much force is normal from watching a training video. And like I said in another video, I was pushing cotton rolls through the barrel with a jag before I found out they are for the chamber.

The patches are another problem. I read that my J Dewey rod can be very tight for some barrels, and when I tried to put a circular cloth patch with solvent in it hardly even wanted to go into the bore guide and then was taking a lot of force without going into the barrel after the throat. It got stuck entering the barrel. I still don't know if I needed more force, I was probably pushing 10 or 12 lbs on the rod, so I backed off and luckily the patch pulled away when I pulled the bore guide out. So I don't know if something's wrong or not.

Do I need more force is or something wrong? You can't tell how much force is normal from watching a training video. And like I said in another video, I was pushing cotton rolls through the barrel with a jag before I found out they are for the chamber.

I like them tight. Tight to the point right before the rod deflects. Shouldn't need to hammer them in there and put a bunch of body weight into the rod.

If the rod deflects then that is too tight and you need to trim the patch down.

You say that you are putting a circle patch on a rod? You mean jag?I read that my J Dewey rod can be very tight for some barrels, and when I tried to put a circular cloth patch with solvent in it hardly even wanted to go into the bore guide and then was taking a lot of force without going into the barrel after the throat.

The rod should be able to freely enter the barrel.

Some say that you shouldnt use a 22cal rod in a 30 cal barrel because it can bend and deflect that much more and to keep it a tight fit. I say screw that, Ill buy one 22 cal rod and just use it in everything I have. My point is that the rod shouldnt be what is introducing resistance.

If you meant j dewey jag, do you have the pointy style?

The pointy style you can (should) stick the properly sized circle patch in the middle and go.

Or the rounded parker hale style?

The rounded type is intended to wrap the patch around as if you were rolling a cigarette.

Personally, I use the parker hale and roll the square patch around. I bought 30 cal square patches, they are too tight in my smaller barrels but I can just cut a 1/4-1/2" off, however much is needed, to fit in the smaller caliber barrels.

Really though all you need to do is cover the brass jags that are sharp and pointy so that they dont scrape on the barrel, the patch should be what is actually making contact with the barrel. How you get to that point is different for every person depending on what they bought and what they actually needed.

Last edited:

Mine are the pointy tip, which I stabbed through a circular cloth patch. I'll try it again with a full circle. I trimmed it and then it went through. Thanks.You say that you are putting a circle patch on a rod? You mean jag?

The rod should be able to freely enter the barrel.

Some say that you shouldnt use a 22cal rod in a 30 cal barrel because it can bend and deflect that much more and to keep it a tight fit. I say screw that, Ill buy one 22 cal rod and just use it in everything I have. My point is that the rod shouldnt be what is introducing resistance.

If you meant j dewey jag, do you have the pointy style?

View attachment 7235996

The pointy style you can (should) stick the properly sized circle patch in the middle and go.

Or the rounded parker hale style?

View attachment 7236002

The rounded type is intended to wrap the patch around as if you were rolling a cigarette.

Personally, I use the parker hale and roll the square patch around. I bought 30 cal square patches, they are too tight in my smaller barrels but I can just cut a 1/4-1/2" off, however much is needed, to fit in the smaller caliber barrels.

Really though all you need to do is cover the brass jags that are sharp and pointy so that they dont scrape on the barrel, the patch should be what is actually making contact with the barrel. How you get to that point is different for every person depending on what they bought and what they actually needed.

Could/probably just be a miss match in labeleing or manufactures, what some people call a 30 call patch is smaller or larger than what someone else calls 30 cal, the difference being what those patches are going onto. If the jag cylinder is large then the larger thicker material 30 cal patch may not fit. If a jag is small then a small 30 cal patch may not have enough size to make up the difference and press against the bore and it will freely glide over the top touching nothing.Mine are the pointy tip, which I stabbed through a circular cloth patch. I'll try it again with a full circle. I trimmed it and then it went through. Thanks.

So much cleaning is voodoo that you sort of just have to figure out how to make it work like you did by cutting the circle down or wrapping it differently etc.

Like spife said. I'm still using the .22 jag that came with the rod. Dabble some sauce on a square patch and poke it in the middle. It should push through with little effort.

If it's hard. STOP. something is wrong.

I was serious about not cleaning it, you can do more harm than good.

If it's hard. STOP. something is wrong.

I was serious about not cleaning it, you can do more harm than good.

Limited cleaning works best for me. I will use a chamber mop and clean the action/bolt after each range trip to remove loose carbon but leave the barrel alone. Shooting suppressed gets dirty quick, even with my bolt rilfe. When I do need to push a patch thru the barrel I use cleaning pellets sized for that bore. Works well for me. Solvent saturated pellet, followed by dry pellets and then a final pellet with CLP if storing for awhile.

*edit. I don't use the super intense cleaning ones. If I have carbon ring I'll use a brush tip. The cotton pellets with solvent work well to remove carbon and debris.

www.brownells.com

www.brownells.com

*edit. I don't use the super intense cleaning ones. If I have carbon ring I'll use a brush tip. The cotton pellets with solvent work well to remove carbon and debris.

WEAPONS CARE SYSTEM PELLETS | Brownells

Innovative and efficient system cleans rifle and handgun barrels with a minimum of effort and mess. Slip two felt pellets on the cleaning rod adapter, apply your favorite solvent and push through the bore to rapidly scrub out dirt and fouling. Pel...

I just used the pointy jag tip with a full circular patch with fp10 on it and it was really difficult going through, like 35 lbs of force needed. I cut the patch down to where a one inch square seemed to work best, it was tight but not extremely tight. Like I said I've heard these dewey rods are too fat for a normal sized patch. Yes, its the right rod they recommend for a 308. Maybe I'll get the next size down. Thanks for all your help.

Thanks. I'm not obsessing on cleaning I was just following Steyr's break in cleaning sequence. I got so many different opinions on break in I decided to go with the manufacturers sequence recommendation to be safest. But I hear you, I'm probably not doing any good with this cleaning. Its just the basic patch wasn't even working. I think this rod is too thick for a normal sized circular patch. I'm sure my barrel is fine, but I'm not happy that it soaked in Eliminator for 24 hours.Like spife said. I'm still using the .22 jag that came with the rod. Dabble some sauce on a square patch and poke it in the middle. It should push through with little effort.

If it's hard. STOP. something is wrong.

I was serious about not cleaning it, you can do more harm than good.

Yes, logically it seems like pushing the rod through shouldn't be too tight or too loose. The middle range worked but the patch was only a 1 inch square I cut. Seems too small.Could/probably just be a miss match in labeleing or manufactures, what some people call a 30 call patch is smaller or larger than what someone else calls 30 cal, the difference being what those patches are going onto. If the jag cylinder is large then the larger thicker material 30 cal patch may not fit. If a jag is small then a small 30 cal patch may not have enough size to make up the difference and press against the bore and it will freely glide over the top touching nothing.

So much cleaning is voodoo that you sort of just have to figure out how to make it work like you did by cutting the circle down or wrapping it differently etc.

I don't think it was copper solvent, it was BoreTech Eliminator.copper solvent is not good to leave. i guess that is at least one reason.

Bore Tech Eliminator website says its safe for the barrel so I'm not going to worry about it.I don't think it was copper solvent, it was BoreTech Eliminator.

I use wipe out and patch out. It says you don’t need to oil or anything when you are done.

I let it sit for 12 hours then patch t out

I let it sit for 12 hours then patch t out

It will get gummy if pools of it are allowed to sit though. You’ll want a nice tight patch to act as an absorbent squeeze.Bore Tech Eliminator website says its safe for the barrel so I'm not going to worry about it.

If a full circle is too tough you might try sticking it 1/3 or 1/5 way off center instead of cutting. If you start one edge of the circle right before the threaded shank part comes up to its full cleaning rod thickness to the base of the point. Cutting a circle smaller takes time and that offsetting of the center could shift that excess material around where cutting isn’t required. It’s all trial and error.

Instead of a patch they make little felt pellets that you stick on the point and push instead of a traditional patch.What does that mean?

WEAPONS CARE SYSTEM PELLETS | Brownells

Innovative and efficient system cleans rifle and handgun barrels with a minimum of effort and mess. Slip two felt pellets on the cleaning rod adapter, apply your favorite solvent and push through the bore to rapidly scrub out dirt and fouling. Pel...

You can drive yourself NUTS researching barrel-cleaning regimens and philosophies. Ask me how I know. Based on your posts, I have a feeling we are quite similar in that regard. And, given what you spent on your rig, I don't blame you for being "OCD" about researching the "best" way to clean it.

I have come to the conclusion that "less is more." Some will tell you that more damage / wear is done to barrels by cleaning than by shooting. Luckily that aligns with my "lazy" attitude towards gun cleaning! It's like going to the gym... I have a hard time getting motivated! But, I LOVE shooting them!

But, I LOVE shooting them!

As such, I have not cleaned my Ruger Precision Rifle 6.5-Creedmoor very much. On average, once every 400 - 500 rounds. I don't scrub it. It's a light cleaning. BTW, I also use Boretech with Dewey rods and jags. And, get this... I've got over 3,500 rounds through the original barrel, and it's still shooting sub-MOA, and often in the 1/2-MOA range, and even down to 1/3-MOA if the planets align. And, that's with factory ammo. Supposedly 6.5 Creedmoor barrels are good for 3,000 rounds at the high end. I'm well past that! Ha!

And, that's with factory ammo. Supposedly 6.5 Creedmoor barrels are good for 3,000 rounds at the high end. I'm well past that! Ha!

I am not nearly as well-versed or experienced as many of the esteemed riflemen who have already commented. But, yeah... it shouldn't take much force at all to push your patch through. If you're having to muscle the patch through, something is wrong. And, it's not fun when you jam one hard enough to get stuck! Been there, done that.

If you have to cut the patches, that's going to get tedious VERY quickly. Just get the right patches. Or maybe try the pellets mentioned above. I haven't tried those, yet. For the jag, I prefer the kind with the point / spear on the end. I found the Parker Hale jag (the roll-on kind) to be tedious. Experiment with various patches / jags and see what works best.

Good luck and enjoy that rifle!

I have come to the conclusion that "less is more." Some will tell you that more damage / wear is done to barrels by cleaning than by shooting. Luckily that aligns with my "lazy" attitude towards gun cleaning! It's like going to the gym... I have a hard time getting motivated!

As such, I have not cleaned my Ruger Precision Rifle 6.5-Creedmoor very much. On average, once every 400 - 500 rounds. I don't scrub it. It's a light cleaning. BTW, I also use Boretech with Dewey rods and jags. And, get this... I've got over 3,500 rounds through the original barrel, and it's still shooting sub-MOA, and often in the 1/2-MOA range, and even down to 1/3-MOA if the planets align.

I am not nearly as well-versed or experienced as many of the esteemed riflemen who have already commented. But, yeah... it shouldn't take much force at all to push your patch through. If you're having to muscle the patch through, something is wrong. And, it's not fun when you jam one hard enough to get stuck! Been there, done that.

If you have to cut the patches, that's going to get tedious VERY quickly. Just get the right patches. Or maybe try the pellets mentioned above. I haven't tried those, yet. For the jag, I prefer the kind with the point / spear on the end. I found the Parker Hale jag (the roll-on kind) to be tedious. Experiment with various patches / jags and see what works best.

Good luck and enjoy that rifle!

Last edited:

Earlier reference to cleaning pellets.What does that mean?

If your not familiar with them google vfg cleaning pellets.

It was a bit off topic but I am a fan of them.

Ps. Dont over clean

You guys and your cleaning regimens...

Wet patch with BoreTech until it comes out clean. Dry patch to get the excess out. But I only clean if/when I notice accuracy starting to fall off. Otherwise, run em hard and put them away wet.

Wet patch with BoreTech until it comes out clean. Dry patch to get the excess out. But I only clean if/when I notice accuracy starting to fall off. Otherwise, run em hard and put them away wet.

Thanks! I just ordered them. Cutting custom sized patches got old real quick.For patches, you should consider the triangle patches made by Boresmith. They can be bought on amazon.com.

https://www.amazon.com/gp/product/B00Q668SCO/ref=ppx_yo_dt_b_asin_title_o06_s00?ie=UTF8&psc=1

I've found that these triangle patches work well and do not require you to side spike the patch, to prevent the patch from jamming, as described on this Bore Tech help page:

https://www.boretech.com/informationcenter/resources/side-spiking

View attachment 7239866

View attachment 7239868

one piece of information that i have never seen a answer for is the time between cleaning.

both sides of the fence:

clean like crazy

clean when groups grow

no problem with either, i do a bit of both depending on my opinion at the time

but not many speak about the duration the rifle sits idle.

for the ones who only clean when the groups open up; how many days/weeks will you let them sit.

EX if you only shoot 20 rounds a year (pure deer hunting rifle)...would you ever clean the barrel?

or would you still wait for the time you take it out and its groups open up?

would the carbon start causing problems of pitting because it absorbs moisture? (stainless barrels)

for the guys who clean down to the bare metal again, would you let it sit 2-3 months dirty/fouled and then clean it to the bore before you go out to the range next spring?

thanks

both sides of the fence:

clean like crazy

clean when groups grow

no problem with either, i do a bit of both depending on my opinion at the time

but not many speak about the duration the rifle sits idle.

for the ones who only clean when the groups open up; how many days/weeks will you let them sit.

EX if you only shoot 20 rounds a year (pure deer hunting rifle)...would you ever clean the barrel?

or would you still wait for the time you take it out and its groups open up?

would the carbon start causing problems of pitting because it absorbs moisture? (stainless barrels)

for the guys who clean down to the bare metal again, would you let it sit 2-3 months dirty/fouled and then clean it to the bore before you go out to the range next spring?

thanks

thanks for the reply but that info is what "has always been said" in one form or another.

running a few parches down the bore with not cleaning to the bare metal, its just reducing the total amount of fouling.

does the thickness of fouling have effects on the bore life itself?

if the no cleaners are true no cleaners then why touch the bore at all..until it opens up?

if the cleaners are true cleaners then its down to the bore each time..or patches every session or brush and patch?

as far as i know there is no standardized criteria/picture of a "semi fouled" barrel.

one patch with only streaks of gray?.. how tight, what material was the patch etc

just playing devils advocate here but anything between 0-100 (clean/dirty) is hearsay, unless there is data?

waiting for more input because this has perked my interest for years

thanks

running a few parches down the bore with not cleaning to the bare metal, its just reducing the total amount of fouling.

does the thickness of fouling have effects on the bore life itself?

if the no cleaners are true no cleaners then why touch the bore at all..until it opens up?

if the cleaners are true cleaners then its down to the bore each time..or patches every session or brush and patch?

as far as i know there is no standardized criteria/picture of a "semi fouled" barrel.

one patch with only streaks of gray?.. how tight, what material was the patch etc

just playing devils advocate here but anything between 0-100 (clean/dirty) is hearsay, unless there is data?

waiting for more input because this has perked my interest for years

thanks

Solvent, oil, CLP; three different things.

Solvent: a thin, watery (sometimes foamy preparation of the same thing) solution of (usually) hydrocarbons which are capable of dissolving powder residue, and sometimes metallic jacket deposits; separating them from the bore surface.

Oil, a lubricant/preservative liquid, usually with some noticeable viscosity, that reduces friction and wear between moving parts, as well as establishing an air/moisture barrier coating, preventing corrosion on metal parts.

CLP, a blend of the above, is intended as an all-in-one "C"leaning, "L"ubricating, and "P"reservative agent.

Brushes are often misunderstood as being an abrasive agent. In the face-off against fouling deposits; they come out a distant second. The solvent does the actual heavy lifting; softening and dissolving the deposits so the brush may dislodge them, exposing more deposits for more solvent to dissolve. In reality, a bronze brush is only marginally more effective than a nylon brush.

My own preference is to employ nylon brushes, and I use them both at the beginning of a cleaning phase, to more thoroughly spread the solvent into the bore/rifling crevices; and at the end, to dislodge the dissolved crud so more solvent and patching can flush the loosened crud out of the bore.

I wipe the cleaning rod down with a shop rag each and every time it comes out of the bore. This eliminates most of the solvent borne crud, some of which is abrasive, from being reinserted into the bore on the next rod pass. When I'm about to remove the brush from the rod, I swish it in a small container of solvent dedicated for this purpose, rather than the main solvent source, to prevent solvent contamination. Solvent can attack a bronze brush, the main reason why I avoid using brass implements in my cleaning process. Brass can turn a patch green/blue just as easily as copper fouling.

I will never fire a bullet down a totally dry bore. I use a mix of alcohol and preservative oil to set the bore up for storage between shooting session, and to provide lubrication for the bullet which is being subjected to 50,000 to 60,000psi bore pressure during its passage. The alcohol allows the mix to spread thin, then evaporates.

I will run a very lightly oil moistened patch down the bore before the first shot to strip out any accumulated particles and establish a minimal oil layer against the bore. The oil can't reduce wear, because the jacket metal can't really wear the bore steel. It may, however, reduce the friction that aids in jacket metal deposition, and may help reduce jacket/carbon fouling.

If, at any part of this process, you find yourself exerting heavy effort, you're doing it wrong. Let the solvent do the work. Solvent and time are the only truly effective factors.

Metal fouling is easier to understand than 'carbon' fouling. Most of the "carbon" fouling is due to powder kernel deterrent coatings. It is added to powder kernels to deter priming spark penetration, thereby controlling kernel ignition rate.

It has been traditionally composed of graphite, which is also an electrical conductor. This provides a crucial safety factor, allowing static electrical accumulations to trickle around, balancing out charge variations between portions of the powder during shipment, when vibration could otherwise generate an explosion triggered by higher voltage electrical discharge within the powder container. I would suggest never shaking powder in the container for extended periods.

Finally, graphite is also a dry lubricant. As bore friction increases, the drag spikes bore pressure and burn rate. Graphite helps the bullet move, easing pressure spikes, and even aiding accuracy. That's why bores need a few shots before accuracy settles down. This is why I oil my bore, so the spikes can be alleviated somewhat prior to the graphite's becoming fully effective.

Moly has gained popularity. It is another dry lubricant. It has been known to complicate cleaning. I do not, for the life of me, understand why someone would wish to combine two dry lubricants in the bore. Life is complicated enough with just the graphite. Moly can be an accuracy aid. It can also be a complication in the cleaning process.

If I ever thought my bore needed more lube, I would be adding graphite to the powder in the container. At least the complications should be less.

Greg

Solvent: a thin, watery (sometimes foamy preparation of the same thing) solution of (usually) hydrocarbons which are capable of dissolving powder residue, and sometimes metallic jacket deposits; separating them from the bore surface.

Oil, a lubricant/preservative liquid, usually with some noticeable viscosity, that reduces friction and wear between moving parts, as well as establishing an air/moisture barrier coating, preventing corrosion on metal parts.

CLP, a blend of the above, is intended as an all-in-one "C"leaning, "L"ubricating, and "P"reservative agent.

Brushes are often misunderstood as being an abrasive agent. In the face-off against fouling deposits; they come out a distant second. The solvent does the actual heavy lifting; softening and dissolving the deposits so the brush may dislodge them, exposing more deposits for more solvent to dissolve. In reality, a bronze brush is only marginally more effective than a nylon brush.

My own preference is to employ nylon brushes, and I use them both at the beginning of a cleaning phase, to more thoroughly spread the solvent into the bore/rifling crevices; and at the end, to dislodge the dissolved crud so more solvent and patching can flush the loosened crud out of the bore.

I wipe the cleaning rod down with a shop rag each and every time it comes out of the bore. This eliminates most of the solvent borne crud, some of which is abrasive, from being reinserted into the bore on the next rod pass. When I'm about to remove the brush from the rod, I swish it in a small container of solvent dedicated for this purpose, rather than the main solvent source, to prevent solvent contamination. Solvent can attack a bronze brush, the main reason why I avoid using brass implements in my cleaning process. Brass can turn a patch green/blue just as easily as copper fouling.

I will never fire a bullet down a totally dry bore. I use a mix of alcohol and preservative oil to set the bore up for storage between shooting session, and to provide lubrication for the bullet which is being subjected to 50,000 to 60,000psi bore pressure during its passage. The alcohol allows the mix to spread thin, then evaporates.

I will run a very lightly oil moistened patch down the bore before the first shot to strip out any accumulated particles and establish a minimal oil layer against the bore. The oil can't reduce wear, because the jacket metal can't really wear the bore steel. It may, however, reduce the friction that aids in jacket metal deposition, and may help reduce jacket/carbon fouling.

If, at any part of this process, you find yourself exerting heavy effort, you're doing it wrong. Let the solvent do the work. Solvent and time are the only truly effective factors.

Metal fouling is easier to understand than 'carbon' fouling. Most of the "carbon" fouling is due to powder kernel deterrent coatings. It is added to powder kernels to deter priming spark penetration, thereby controlling kernel ignition rate.

It has been traditionally composed of graphite, which is also an electrical conductor. This provides a crucial safety factor, allowing static electrical accumulations to trickle around, balancing out charge variations between portions of the powder during shipment, when vibration could otherwise generate an explosion triggered by higher voltage electrical discharge within the powder container. I would suggest never shaking powder in the container for extended periods.

Finally, graphite is also a dry lubricant. As bore friction increases, the drag spikes bore pressure and burn rate. Graphite helps the bullet move, easing pressure spikes, and even aiding accuracy. That's why bores need a few shots before accuracy settles down. This is why I oil my bore, so the spikes can be alleviated somewhat prior to the graphite's becoming fully effective.

Moly has gained popularity. It is another dry lubricant. It has been known to complicate cleaning. I do not, for the life of me, understand why someone would wish to combine two dry lubricants in the bore. Life is complicated enough with just the graphite. Moly can be an accuracy aid. It can also be a complication in the cleaning process.

If I ever thought my bore needed more lube, I would be adding graphite to the powder in the container. At least the complications should be less.

Greg

Last edited:

To me, what doesn't add up logically about using solvent is the question of whether or not its a lubricant or a stripper of lubricant. How does it make sense to end the barrel cleaning process using solvent and not with oiling the barrel? The different solvent manufacturers imply that it cleans and lubricates. Then what is the point of the bore guide? I thought this was so you don't strip lubricant in the receiver area. I noticed that bore tech eliminator doesn't evaporate and remains oily to the touch. So why do I need a bore guide? Why do I need to keep a lubricant out of the receiver?

I'm sure this has been covered ad nauseam at this point, but I'm gonna answer your OP anyway because it's the internet.

First - BoreTech, KG-12, whatever product you're using on your bore should be a solvent. Hell, use Sweet's if you want (not my thing...really no need for it, even if the risk is easily mitigated). Solvents are not lubricants. Copper and carbon can be tough to remove - pick the right tool (solvent, not 3-in-1 products) for the job.

Second - as a matter of convenience, a bore guide does a nice job of keeping your solvent of choice out of your action. That means less time wiping down/neutralizing and then re-oiling your rifle's action. As stated above - proper solvents are not lube, don't use them to protect your rifle.

Moving on, you SHOULD condition your bore for storage or field use appropriately. There's no magic to it. If your bore rusts/pits/corrodes, your performance will suffer. Buying 3-in-1 products is, at best, false economy. You'll go through plenty of cleaning products - whether you buy two products every so often or one product more frequently makes not a scrap of diffrence to your theoretical bottom line. When you consider wasting time and effort with a 3-in-1 product that simply doesn't do the job as effectively...

thanks for the reply but that info is what "has always been said" in one form or another.

running a few parches down the bore with not cleaning to the bare metal, its just reducing the total amount of fouling.

does the thickness of fouling have effects on the bore life itself?

if the no cleaners are true no cleaners then why touch the bore at all..until it opens up?

if the cleaners are true cleaners then its down to the bore each time..or patches every session or brush and patch?

as far as i know there is no standardized criteria/picture of a "semi fouled" barrel.

one patch with only streaks of gray?.. how tight, what material was the patch etc

just playing devils advocate here but anything between 0-100 (clean/dirty) is hearsay, unless there is data?

waiting for more input because this has perked my interest for years

thanks

Every barrel is an individual entity. Guidelines and standard practices are just that. Often times, they yield acceptable results. However, if you want to have the right answer for your rifle and your barrel, log the fouling and bore conditions as well as the results of your cleaning just like you log the results of your shots. What is effective will become apparent.

It's worth noting that if you depend on your rifle, cleaning is a prophylactic measure - you conduct Preventative Maintenance Checks and Services (PMCS) BEFORE the problem degrades your performance. To that end, your cleaning regime can be categorized into to different types of services conducted at different intervals. The "what" and "how often" can be a recommendation, a standard practice, or something you develop.

The reason it's worth cleaning your barrel as a prophylactic is to prevent degradation of the bore. Fouling can trap moisture and/or encourage corrosion. There are a number of shooters that run stainless barrels and shoot frequently enough that this of minimal concern to them.

Every barrel is an individual entity. Guidelines and standard practices are just that. Often times, they yield acceptable results. However, if you want to have the right answer for your rifle and your barrel, log the fouling and bore conditions as well as the results of your cleaning just like you log the results of your shots. What is effective will become apparent.

It's worth noting that if you depend on your rifle, cleaning is a prophylactic measure - you conduct Preventative Maintenance Checks and Services (PMCS) BEFORE the problem degrades your performance. To that end, your cleaning regime can be categorized into to different types of services conducted at different intervals. The "what" and "how often" can be a recommendation, a standard practice, or something you develop.

The reason it's worth cleaning your barrel as a prophylactic is to prevent degradation of the bore. Fouling can trap moisture and/or encourage corrosion. There are a number of shooters that run stainless barrels and shoot frequently enough that this of minimal concern to them.

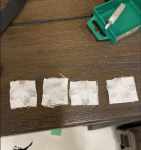

I'm starting to think I need to use a brush because I ran eight patches with Boretech Eliminator and then this mop with Eliminator(which I should have done first), yet look at this mop, its still dirty. Finally I ran four dry patches that came out as shown. I don't know if that's good enough or not.

Next time I'll do:

- mop soaked in eliminator first and let it soak a half hour

- nylon brush(do you put solvent on the brush? or would it just run off) a few times

- patches with eliminator until clean-ish

- dry patches

- Boretech Friction Guard gun oil

Also, can I pull the brush back toward the chamber and then through again? They say don't pull from muzzle to chamber but now I don't know when you're not supposed to do that.

And this is all for the bore, I still don't know when to clean the chamber. I've never cleaned the chamber and I've shot about 100 rounds since I bought the gun. That's a lot of questions, I know.

Attachments

I split the difference and do a couple pulls of a BoreSnake every 150-200 rounds or so.You are probably better off not cleaning.

I'm starting to think I need to use a brush because I ran eight patches with Boretech Eliminator and then this mop with Eliminator(which I should have done first), yet look at this mop, its still dirty. Finally I ran four dry patches that came out as shown. I don't know if that's good enough or not.

Next time I'll do:

I think I'm going to buy a second bore guide so I'm not cleaning up the bore guide when I'm trying to get into the bore, especially transitioning from solvent to oil.

- mop soaked in eliminator first and let it soak a half hour

- nylon brush(do you put solvent on the brush? or would it just run off) a few times

- patches with eliminator until clean-ish

- dry patches

- Boretech Friction Guard gun oil

Also, can I pull the brush back toward the chamber and then through again? They say don't pull from muzzle to chamber but now I don't know when you're not supposed to do that.

And this is all for the bore, I still don't know when to clean the chamber. I've never cleaned the chamber and I've shot about 100 rounds since I bought the gun. That's a lot of questions, I know.

From what I gather the reason most people clean breech to muzzle is to push everything out of the muzzle and not back into the chamber and action.

With that in mind you can work a mop or brush back and forth.

to my eyes i think you're fine...

the company i purchased my barrel from advocated never to use anything harder than a nylon brush or patches so that's what i do.

i would advocate a bore guide......mine is a simple one from Sinclair, not very expensive and seems to do the job well. it does have a small o-ring that occasionally wears and requires replacing.

I do not think that you have to clean till the patches come out looking just as clean as when they went in. Mine always show a little bit of darkness (Schmutz), probably even a bit darker than your photos illustrate.

i live in a coastal region so as a final run i always lightly oil the barrel inside and out. I'll gently wipe out the barrel prior to shooting with a dry pellet or patch.

I do favor the pellets, i do not usually find myself gravitating to the latest gimmick or toy but they seem to do a very nice job and they also seem to center the rod nicely...It seems that with the pellets and the bore guide i'm really minimizing any insult from the rod as the rod is more stable at two points.

the company i purchased my barrel from advocated never to use anything harder than a nylon brush or patches so that's what i do.

i would advocate a bore guide......mine is a simple one from Sinclair, not very expensive and seems to do the job well. it does have a small o-ring that occasionally wears and requires replacing.

I do not think that you have to clean till the patches come out looking just as clean as when they went in. Mine always show a little bit of darkness (Schmutz), probably even a bit darker than your photos illustrate.

i live in a coastal region so as a final run i always lightly oil the barrel inside and out. I'll gently wipe out the barrel prior to shooting with a dry pellet or patch.

I do favor the pellets, i do not usually find myself gravitating to the latest gimmick or toy but they seem to do a very nice job and they also seem to center the rod nicely...It seems that with the pellets and the bore guide i'm really minimizing any insult from the rod as the rod is more stable at two points.

Bartlein says clean lightly every 100 rounds, so that is what I do. Boretech seems like a good solvent and it can be used to store the firearm.

what happens if there’s a lot of oil in the bore and you forgot to run a dry patch and then you fired the rifle? my guess is the bullet would hydroplane over the oil and then the heat would burn the oil leaving more fouling than you would have had. or if there’s enough force between the copper jacket and the bore it could shove all the oil out but that seems less likely because that oil has a strong adhesion quality, it clingsto my eyes i think you're fine...

the company i purchased my barrel from advocated never to use anything harder than a nylon brush or patches so that's what i do.

i would advocate a bore guide......mine is a simple one from Sinclair, not very expensive and seems to do the job well. it does have a small o-ring that occasionally wears and requires replacing.

I do not think that you have to clean till the patches come out looking just as clean as when they went in. Mine always show a little bit of darkness (Schmutz), probably even a bit darker than your photos illustrate.

i live in a coastal region so as a final run i always lightly oil the barrel inside and out. I'll gently wipe out the barrel prior to shooting with a dry pellet or patch.

I do favor the pellets, i do not usually find myself gravitating to the latest gimmick or toy but they seem to do a very nice job and they also seem to center the rod nicely...It seems that with the pellets and the bore guide i'm really minimizing any insult from the rod as the rod is more stable at two points.

guys, you see this patch third from the left? It almost seems to say that the groove or I should say the four grooves are very wide. Why would they design the barrel like that? I mean only four of eight edges matter, right? each trench has two edges but only one edge is experiencing heavy force spinning the round.I'm starting to think I need to use a brush because I ran eight patches with Boretech Eliminator and then this mop with Eliminator(which I should have done first), yet look at this mop, its still dirty. Finally I ran four dry patches that came out as shown. I don't know if that's good enough or not.

Next time I'll do:

I think I'm going to buy a second bore guide so I'm not cleaning up the bore guide when I'm trying to get into the bore, especially transitioning from solvent to oil.

- mop soaked in eliminator first and let it soak a half hour

- nylon brush(do you put solvent on the brush? or would it just run off) a few times

- patches with eliminator until clean-ish

- dry patches

- Boretech Friction Guard gun oil

Also, can I pull the brush back toward the chamber and then through again? They say don't pull from muzzle to chamber but now I don't know when you're not supposed to do that.

And this is all for the bore, I still don't know when to clean the chamber. I've never cleaned the chamber and I've shot about 100 rounds since I bought the gun. That's a lot of questions, I know.

I wonder if on some of these copper jacketed bullets with a lead core these trenches spin the copper around the lead. maybe some manufacturers don’t realize that’s happening.

guys, you see this patch third from the left? It almost seems to say that the groove or I should say the four grooves are very wide. Why would they design the barrel like that? I mean only four of eight edges matter, right? each trench has two edges but only one edge is experiencing heavy force spinning the round.

I wonder if on some of these copper jacketed bullets with a lead core these trenches spin the copper around the lead. maybe some manufacturers don’t realize that’s happening.

LmAO

I'm pretty certain that both the barrel manufacturers and the bullet manufacturers know what they are doing. That also pertains to how the barrels and bullets react when fired.

If the copper jacket was rotating around the lead core, the bullet would disintegrate. It is true that some bullets do disintegrate after leaving the barrel when the bullet is pushed beyond its design.

There is a type of rifling that is similar to what you have described offered by Triarc Systems

TRACK™ is a proprietary rifling known as Single Edge Polygonal (SEP) available through TRIARC Systems. The primary function of this innovation is to provide an improved rifling for a gun barrel, which has a single edge area and a polygonal area separating the grooves. In essence, it is a combination of standard and polygonal rifling.This hybrid reduces any substantial deformation of the bullet due to its minimal engraving. It allows the bullet to move more symmetrically along the barrel, enabling a straighter line towards the target. Furthermore, the tighter seal of the projectile reduces forward escaping gases, and therefore, minimal loss of gas pressures. Ultimately, this design has the capabilities of shooting match grade ammunition at sub MOA accuracy.

View attachment 7271302

My bullet is going from 0 rpm to 3600rpm in a 1.3ms time period. That's incredibly high moment of inertia for two soft metals. The barrel is 1:10 twist and muzzle velocity is 3000fps. If it was 1:12 twist then the rpm would be 3000 rpm, but its faster than that by (6/5)ths, making it 3600rpm. The rifling isn't turning the lead, the copper is. Its soft metal on even softer and much heavier metal, yet I don't see from Hornady's description or graphics that there's anything besides metallurgical adhesion keeping the copper from slipping over the lead, or from keeping the lead just inside the boundary between the two from slipping. If they took before and after cross sections and examined the metal grain patterns they might be able to see if the grains are spiraling or stable. I'm not doubting their engineering, I'm just curious what is keeping the copper from moving over the lead. My guess is the copper and lead both are being smeared in a spiral pattern but to what extent I don't know.I'm pretty certain that both the barrel manufacturers and the bullet manufacturers know what they are doing. That also pertains to how the barrels and bullets react when fired.

If the copper jacket was rotating around the lead core, the bullet would disintegrate. It is true that some bullets do disintegrate after leaving the barrel when the bullet is pushed beyond its design.

There is a type of rifling that is similar to what you have described offered by Triarc Systems

TRACK™ is a proprietary rifling known as Single Edge Polygonal (SEP) available through TRIARC Systems. The primary function of this innovation is to provide an improved rifling for a gun barrel, which has a single edge area and a polygonal area separating the grooves. In essence, it is a combination of standard and polygonal rifling.This hybrid reduces any substantial deformation of the bullet due to its minimal engraving. It allows the bullet to move more symmetrically along the barrel, enabling a straighter line towards the target. Furthermore, the tighter seal of the projectile reduces forward escaping gases, and therefore, minimal loss of gas pressures. Ultimately, this design has the capabilities of shooting match grade ammunition at sub MOA accuracy.

View attachment 7271302

Similar threads

- Replies

- 0

- Views

- 60

Rifle Competition Events

Cleaning for Competitions

- Replies

- 86

- Views

- 5K

- Replies

- 0

- Views

- 576