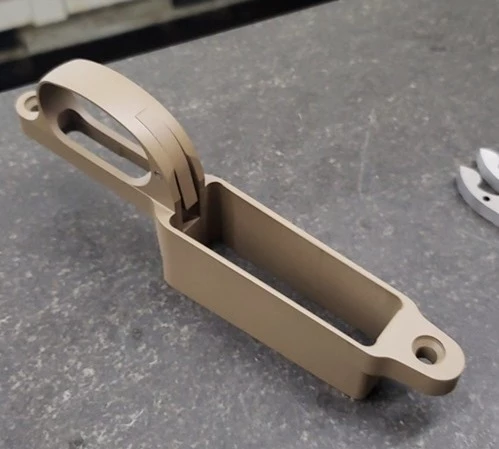

Our new HTR style DBM:

Anyone who has used or fitted a detachable magazine setup on a rifle has inevitably run into the situation where a particular brand of magazine doesn't work.

The problem is there is no standard. No hall of records where you anoint yourself in Hoppes and pay homage to gain the magic answer. We too lack this secret handshake. It's been a problem from day one and what we set out to solve with these parts.

Our solution is to offer magazine specific latch mechanisms.

The LRI DBM works properly when the action is bedded to the stock's showline edge and the floor metal is flush mounted on the bottom. (On a normal stock with a 2" height between showline and belly at the tang/showline intersection) At this installed height, the magazine will present the case at the optimum height (on a .700" dia bolt, such as a Remington M700 or the many clones/derivatives).

Determining the proper installed height:

Here at LRI, we refer to this as the "figure 8". Simply to mean the primer is tangent to the 6 o'clock position of the receiver bore.The 2 imaginary circles create an inverted figure 8.

Having this ensures the case rim/head is exposed for proper overlap on bolt nose. Its a proven rule that will consistently deliver the most reliable means of feeding cartridges. All cartridges; long, short, or fat, it doesn't matter.

The Obendorf latch design was chosen because it is elegant and simple. Our latch observes the need for firm spring pressure and we were careful to ensure it has the proper geometry to stay put during heavy recoil. Lightweight hunting rifles are the target audience for this piece (other versions to follow) so ensuring the gun doesn't "gut itself like a fish" is important.

The LRI DBM's are available in two finishes; Type III hard coat anodized and an As Machined / "In The White" version for those who wish to coat the parts to handshake with a full build.

We didn't stop there. LRI is a gunmaking business first and foremost, which means we understand the challenges that industry colleagues face. We support our products with detailed technical drawings and code for those fortunate to have CNC milling machines!

SOLID MODEL_STEP FORMAT

DRAWING_1

DRAWING_2

CNC INLETTING CODE_HAAS FORMAT

TOOL PACKAGE AND SETUP

Manufacturing:

These floor metals begin life as a 2-3/4lb piece of 6061 T651 AL bar stock. When finished they weigh a petite 3.1 ounces. The parts are 5 axis CNC machined on our Haas UMC-750 5 axis CNC mill and programmed with state of the art CAD/CAM software.

The advantage 5 axis offers is the ability to access the parts on 5 of its six sides. Doing so is powerful because tolerance stacking errors caused by moving from one fixture to another is almost completely eliminated. This goes a long way towards ensuring the parts fit the rifle stock and mating components.

The release levers are machined from 4130 Chromoly steel on our Kitamura MyCenter 3Xi 4 axis CNC milling center. The ultra rigid box way construction used by Kitamura is perfect for machining tough/abrasive tool grade steels.

Next:

A neat little lighter weight hunting rig we just wrapped up.

6lbs, 10oz.

Anyone who has used or fitted a detachable magazine setup on a rifle has inevitably run into the situation where a particular brand of magazine doesn't work.

The problem is there is no standard. No hall of records where you anoint yourself in Hoppes and pay homage to gain the magic answer. We too lack this secret handshake. It's been a problem from day one and what we set out to solve with these parts.

Our solution is to offer magazine specific latch mechanisms.

The LRI DBM works properly when the action is bedded to the stock's showline edge and the floor metal is flush mounted on the bottom. (On a normal stock with a 2" height between showline and belly at the tang/showline intersection) At this installed height, the magazine will present the case at the optimum height (on a .700" dia bolt, such as a Remington M700 or the many clones/derivatives).

Determining the proper installed height:

Here at LRI, we refer to this as the "figure 8". Simply to mean the primer is tangent to the 6 o'clock position of the receiver bore.The 2 imaginary circles create an inverted figure 8.

Having this ensures the case rim/head is exposed for proper overlap on bolt nose. Its a proven rule that will consistently deliver the most reliable means of feeding cartridges. All cartridges; long, short, or fat, it doesn't matter.

The Obendorf latch design was chosen because it is elegant and simple. Our latch observes the need for firm spring pressure and we were careful to ensure it has the proper geometry to stay put during heavy recoil. Lightweight hunting rifles are the target audience for this piece (other versions to follow) so ensuring the gun doesn't "gut itself like a fish" is important.

The LRI DBM's are available in two finishes; Type III hard coat anodized and an As Machined / "In The White" version for those who wish to coat the parts to handshake with a full build.

We didn't stop there. LRI is a gunmaking business first and foremost, which means we understand the challenges that industry colleagues face. We support our products with detailed technical drawings and code for those fortunate to have CNC milling machines!

SOLID MODEL_STEP FORMAT

DRAWING_1

DRAWING_2

CNC INLETTING CODE_HAAS FORMAT

TOOL PACKAGE AND SETUP

Manufacturing:

These floor metals begin life as a 2-3/4lb piece of 6061 T651 AL bar stock. When finished they weigh a petite 3.1 ounces. The parts are 5 axis CNC machined on our Haas UMC-750 5 axis CNC mill and programmed with state of the art CAD/CAM software.

The advantage 5 axis offers is the ability to access the parts on 5 of its six sides. Doing so is powerful because tolerance stacking errors caused by moving from one fixture to another is almost completely eliminated. This goes a long way towards ensuring the parts fit the rifle stock and mating components.

The release levers are machined from 4130 Chromoly steel on our Kitamura MyCenter 3Xi 4 axis CNC milling center. The ultra rigid box way construction used by Kitamura is perfect for machining tough/abrasive tool grade steels.

Next:

A neat little lighter weight hunting rig we just wrapped up.

6lbs, 10oz.