This one is a present for someone close to me. As a teen, I spent my summers working on a big grain farm in North Dakota. The owner is more of a Dad to me than mine ever was. He has a birthday coming up and I felt the urge to try and say thank you.

I chambered it in 6.5mm Creed. It works, ammo is easy to find, relatively affordable, and the accuracy/easy-to-shoot behavior of the cartridge fits well for something like this. He's now in his mid-70s but still sharp as a tack.

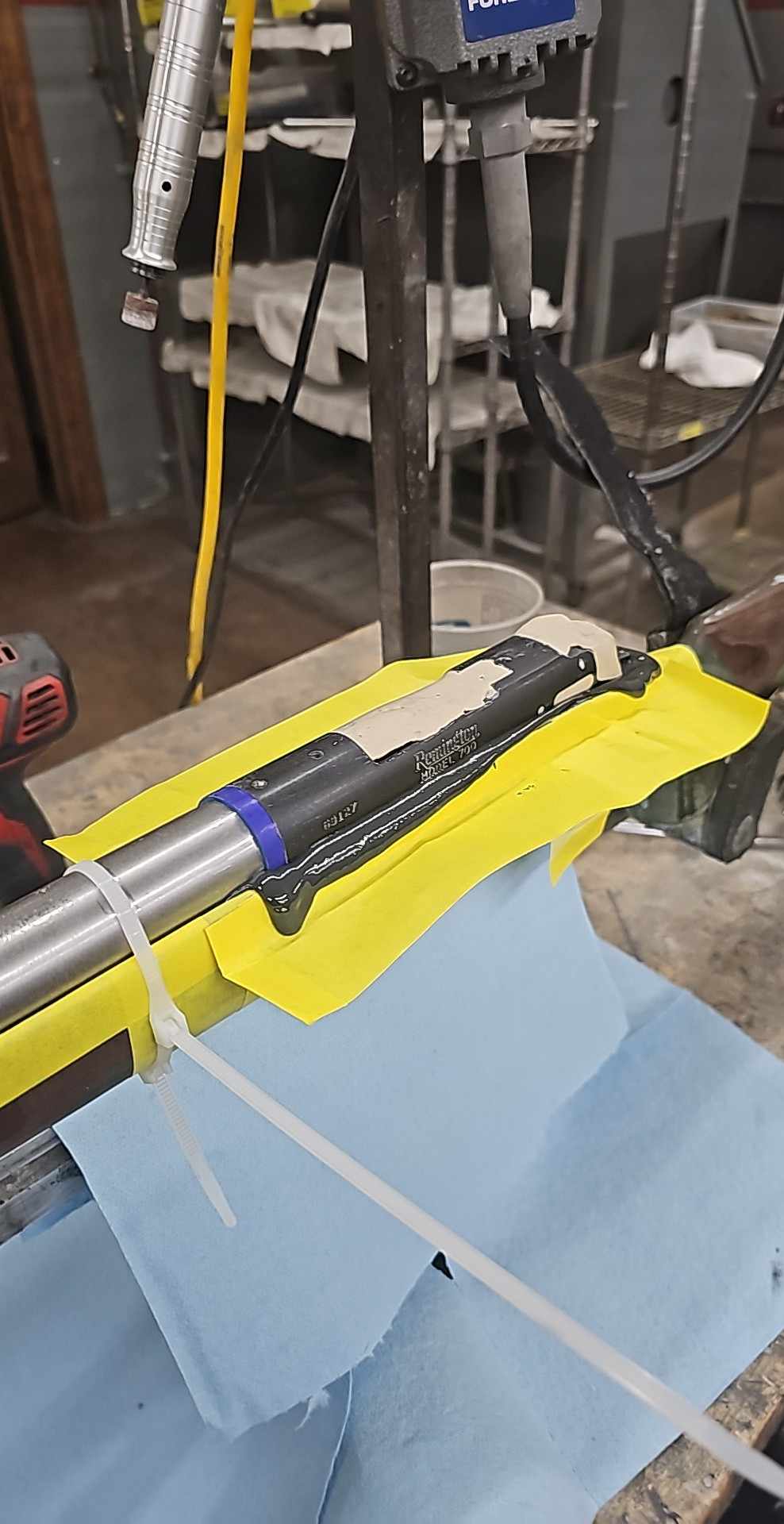

Around ten years ago a WY Highway Patrolman stopped by to have some work done. He had a 5-digit SN M700. Some quick negotiations rewarded me with his action. It's been in my safe ever since so I decided to put it to work for this. Once I started, I noticed the cocking cam at the back of the bolt needed a lot of work. At some point in its life, somebody messed with it and it didn't go well. I rolled the dice a little for the fix and it worked far better than I had ever expected. I stitched it up with some air-hardening filler rod and a TIG torch. Turned it back down and noticed a couple of small pits where I'd missed a few spots. Silicon bronze filler rod is a pet favorite of mine for stuff like this. I call it "machinist's bondo" as it's great for patching up small inclusions. The best part is, that you don't have to melt the substrate to use it. Just get it hot and dab the rod at the flame kernel on the torch. It'll melt and adhere to the part without any drama. The photos show a few small traces of goldish-colored stuff. That's the S.B. filler.

Cutting the cam feature again was pretty simple. A 4th axis on the mill makes quick work of it.

With that fixed, tuning up the receiver came next. The 5-axis process we've had for a few years now makes this pretty simple. In addition, I did the base holes, added a side release, and set it up for the M40 A1 style base we make.

With the lugs cleaned up, I put the bolt handle back on it. I do this last so that the PE can be restored because chewing on the lugs sets everything back some.

I've always liked how a skeletonized handle looks from us so I had Kalyb here do it for me. While he was at it, I had him run our jeweling program over the bolt cylinder as well.

After all that, setting up the extractor and dual ejectors was next.

Since the Remington BR, parts are a whole lot more work to source. Shrouds were tough to find at one point, so we ran a batch ourselves. This is one of our SS shrouds that we faceted for this build.

Clip Slotting...

With the receiver/bolt work done, onto hanging a stick on it. M24 contour from K/P.

Stockwork...

I ordered a bunch of blank M40s from McMillan. I was not expecting "smear" finish flat tops, but that's what I got. Inlet the top half, bed it, then back in the machine for the cleanup followed by flipping it over to do the bottom side. I stuck the presentation pad on here and wrapped it up by sticking a couple optional pieces to it. Bipod rail and flush cup hardware. The current trend by some stock makers to gut the inlet like a fish doesn't appeal to me. I get why they do it, the web between the trigger and magwell does tend to crack pretty easily. I started pinning these a long time ago. It's been a good fix for us.

I chambered it in 6.5mm Creed. It works, ammo is easy to find, relatively affordable, and the accuracy/easy-to-shoot behavior of the cartridge fits well for something like this. He's now in his mid-70s but still sharp as a tack.

Around ten years ago a WY Highway Patrolman stopped by to have some work done. He had a 5-digit SN M700. Some quick negotiations rewarded me with his action. It's been in my safe ever since so I decided to put it to work for this. Once I started, I noticed the cocking cam at the back of the bolt needed a lot of work. At some point in its life, somebody messed with it and it didn't go well. I rolled the dice a little for the fix and it worked far better than I had ever expected. I stitched it up with some air-hardening filler rod and a TIG torch. Turned it back down and noticed a couple of small pits where I'd missed a few spots. Silicon bronze filler rod is a pet favorite of mine for stuff like this. I call it "machinist's bondo" as it's great for patching up small inclusions. The best part is, that you don't have to melt the substrate to use it. Just get it hot and dab the rod at the flame kernel on the torch. It'll melt and adhere to the part without any drama. The photos show a few small traces of goldish-colored stuff. That's the S.B. filler.

Cutting the cam feature again was pretty simple. A 4th axis on the mill makes quick work of it.

With that fixed, tuning up the receiver came next. The 5-axis process we've had for a few years now makes this pretty simple. In addition, I did the base holes, added a side release, and set it up for the M40 A1 style base we make.

With the lugs cleaned up, I put the bolt handle back on it. I do this last so that the PE can be restored because chewing on the lugs sets everything back some.

I've always liked how a skeletonized handle looks from us so I had Kalyb here do it for me. While he was at it, I had him run our jeweling program over the bolt cylinder as well.

After all that, setting up the extractor and dual ejectors was next.

Since the Remington BR, parts are a whole lot more work to source. Shrouds were tough to find at one point, so we ran a batch ourselves. This is one of our SS shrouds that we faceted for this build.

Clip Slotting...

With the receiver/bolt work done, onto hanging a stick on it. M24 contour from K/P.

Stockwork...

I ordered a bunch of blank M40s from McMillan. I was not expecting "smear" finish flat tops, but that's what I got. Inlet the top half, bed it, then back in the machine for the cleanup followed by flipping it over to do the bottom side. I stuck the presentation pad on here and wrapped it up by sticking a couple optional pieces to it. Bipod rail and flush cup hardware. The current trend by some stock makers to gut the inlet like a fish doesn't appeal to me. I get why they do it, the web between the trigger and magwell does tend to crack pretty easily. I started pinning these a long time ago. It's been a good fix for us.

Last edited: