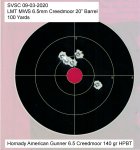

I installed a new LMT 20” 6.5mm Creedmoor barrel on my LMT MWS and took it out to the range today. No malfunctions, but I noticed groves being cut in the case necks. These are appearing on the extractor side of the case. I am guessing these are coming from the inside of the barrel extension on the extractor side. The bolt has duel extractors and I believe the extracted fired cases are being pulled hard against the inside of the barrel extension and there must be sharp edges cutting into the necks. Has anyone seen this before? I am wondering if the cases are not suitable for reloading. I have not noticed this on cases ejected from my 308 MWS.

NOTE: I did cycle several unfired cartridges through the rifle. No marks were left. On the bullets or cases.

Ammo: Hornady American Gunner 6.5 Creedmoor 140 gr HPBT

I measured ten random cases with a RCBS Case Gauge

Measurements Before Firing

Four at +0.001

Three at 0.000

One at -0.001

Two at -0.002

Three at -0.003

Measurements After Firing

Four at +0.005

Four at +0.007

Two at +0.008

I don’t have a No Go gauge for 6.5 mm Creedmoor and I am wondering if +0.007 and above is heading in the No Go area.

NOTE: I did cycle several unfired cartridges through the rifle. No marks were left. On the bullets or cases.

Ammo: Hornady American Gunner 6.5 Creedmoor 140 gr HPBT

I measured ten random cases with a RCBS Case Gauge

Measurements Before Firing

Four at +0.001

Three at 0.000

One at -0.001

Two at -0.002

Three at -0.003

Measurements After Firing

Four at +0.005

Four at +0.007

Two at +0.008

I don’t have a No Go gauge for 6.5 mm Creedmoor and I am wondering if +0.007 and above is heading in the No Go area.