I have been shooting my factory Remington 700 Long Range chambered in 7mm remington magnum and I am now on my 3 firing of the same 20 cases I started with and have an problem.

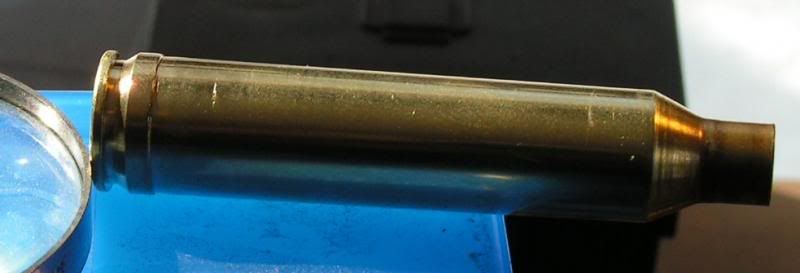

First firing, no issue... second, I had maybe a third of the cases not want to extract very easy... Third firing, every case was very hard to extract... almost like the brass was welding to the chamber wall. I am using a Redding body die to resize the case and bump the shoulder back .002-.003 and a bushing neck die to do the neck.

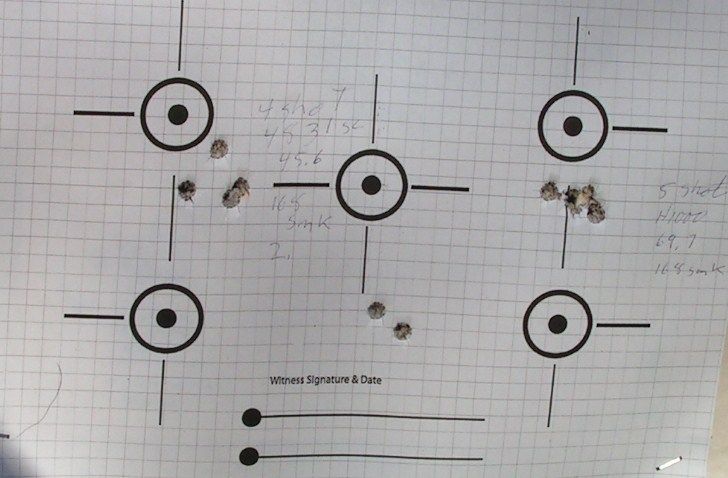

I know I am not running my load too hot as it now happens no matter what charge I use. I was doing OCW's from 68g thru 70g of H1000 with 168 smk's. Looking things over on the rifle I am not getting any help from the bolt handle in primary extraction which seems to be normal for Remington these days. (The bolt handle angle cut is not contacting the angle cut on the action- I assume that’s what smiths call primary extraction...) Brass and primers show no signs of over pressure, nor have I had to trim but a few after the first firing.

So I started to research which lead me to this, scroll down to the thrid product.

Innovative Technologies - Reloading Equipment

I have noticed that brass has been getting tighter to chamber and after reading about this Die maybe that is what is needed... But my concern is still going to be more extraction than chambering. I even thought of purchasing a headspace gauge (go and nogo) to check the barrel against and make adjustments if needed to see if that would help (since Remington likes to use .005-.006 over minimum).

Any thoughts... or better, experience with this???

First firing, no issue... second, I had maybe a third of the cases not want to extract very easy... Third firing, every case was very hard to extract... almost like the brass was welding to the chamber wall. I am using a Redding body die to resize the case and bump the shoulder back .002-.003 and a bushing neck die to do the neck.

I know I am not running my load too hot as it now happens no matter what charge I use. I was doing OCW's from 68g thru 70g of H1000 with 168 smk's. Looking things over on the rifle I am not getting any help from the bolt handle in primary extraction which seems to be normal for Remington these days. (The bolt handle angle cut is not contacting the angle cut on the action- I assume that’s what smiths call primary extraction...) Brass and primers show no signs of over pressure, nor have I had to trim but a few after the first firing.

So I started to research which lead me to this, scroll down to the thrid product.

Innovative Technologies - Reloading Equipment

I have noticed that brass has been getting tighter to chamber and after reading about this Die maybe that is what is needed... But my concern is still going to be more extraction than chambering. I even thought of purchasing a headspace gauge (go and nogo) to check the barrel against and make adjustments if needed to see if that would help (since Remington likes to use .005-.006 over minimum).

Any thoughts... or better, experience with this???

Last edited: