Perrenial question dept;

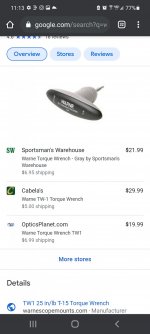

Use Loctite on ring cap and/or base screws?

Dont want permanent so red is out. Maybe blue but given the small hex/torx screws and ease of stripping the socket I think maybe not. That leaves purple.

Use Loctite on ring cap and/or base screws?

Dont want permanent so red is out. Maybe blue but given the small hex/torx screws and ease of stripping the socket I think maybe not. That leaves purple.