I've recently had to downsize my shop and ended up getting rid of my knee mill. Was only really using it to drill the occasional gas port on an AR barrel and figured I could do that with a milling attachment on the lathe. I thought there were more options available for this, but it appears that that's only the case for the tiny lathes like the Sherline and the Taig. Wondering if anyone has rigged something up on a lager lathe like a PM1236 or similar? What milling slide did you use and how did you attach it to the slide? Thinking that attaching the angle bracket to a plate on the cross slide is probably the easiest thing...

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Milling Slide for Large Lathe?

- Thread starter kombayotch

- Start date

I am interested in this response. I use a Bridgeport and LaBlonde lathe. My stupid - Didn't know you could "mill" on a lathe.

Couldn't you put the barrel in something like a boring bar holder held in the steady rest ? Drill chuck in the three jaw feed with the Z axis ? Up and down would be the tough adjustment but it could be done .

Another option ....

Another option ....

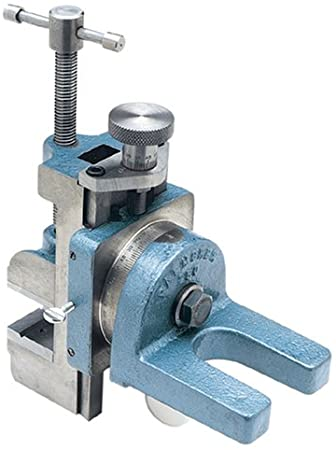

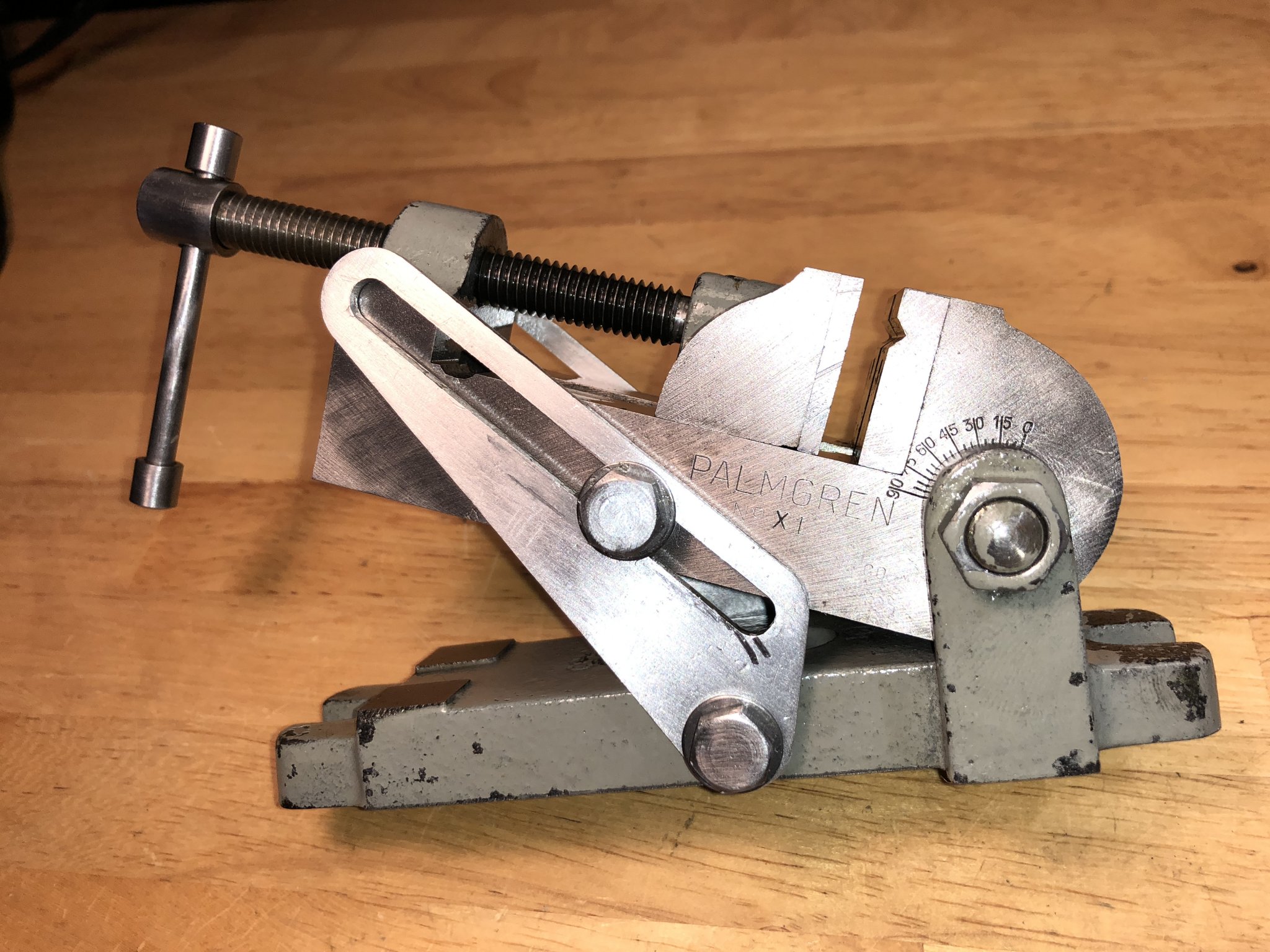

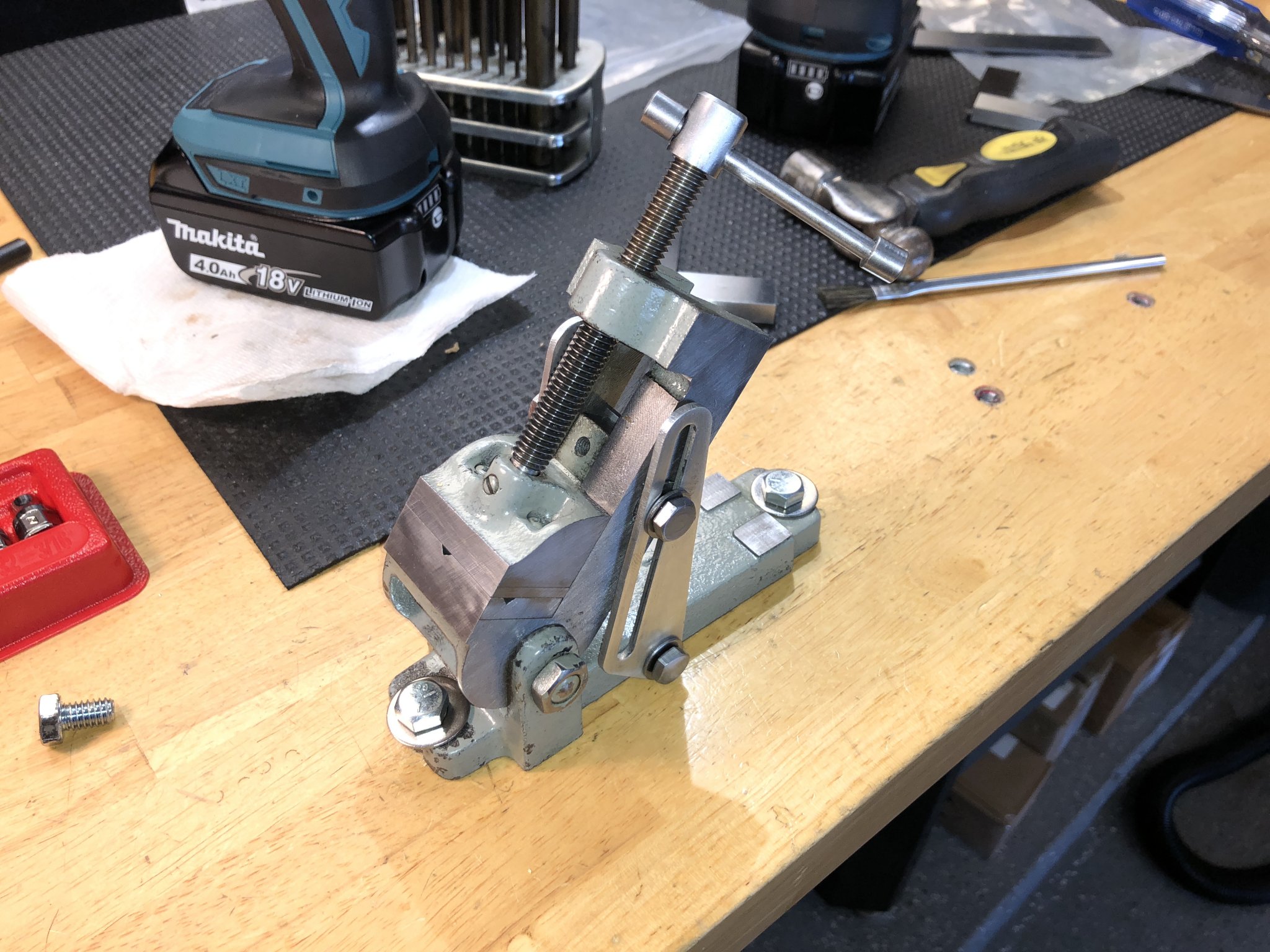

Old School style Palmgren milling attachment for lathe.

Would only recommend if you absolutely couldn't access a mill. For small parts and small metal removal it could do what you want.

They used to have different versions of this scaled to different size lathes.

./

Would only recommend if you absolutely couldn't access a mill. For small parts and small metal removal it could do what you want.

They used to have different versions of this scaled to different size lathes.

./

The Palmgren milling attachments show up often on ebay. Should have got one years ago just because but have never really needed.

I understand you can use them if you go slow, small and close. Every machinist I have talked to thinks they are a joke. You are adding stresses that mills are designed to handle but lathes are not. Good luck all the same. I would be curious to read any success stories on them.

I believe the OP wants to drill gas ports in barrels that wouldnt stress a lathe too much if at all.

Yes, if I needed a mill, I would have just kept the knee mill.

Drilling new.Are you modifying an existing port or drilling new ?

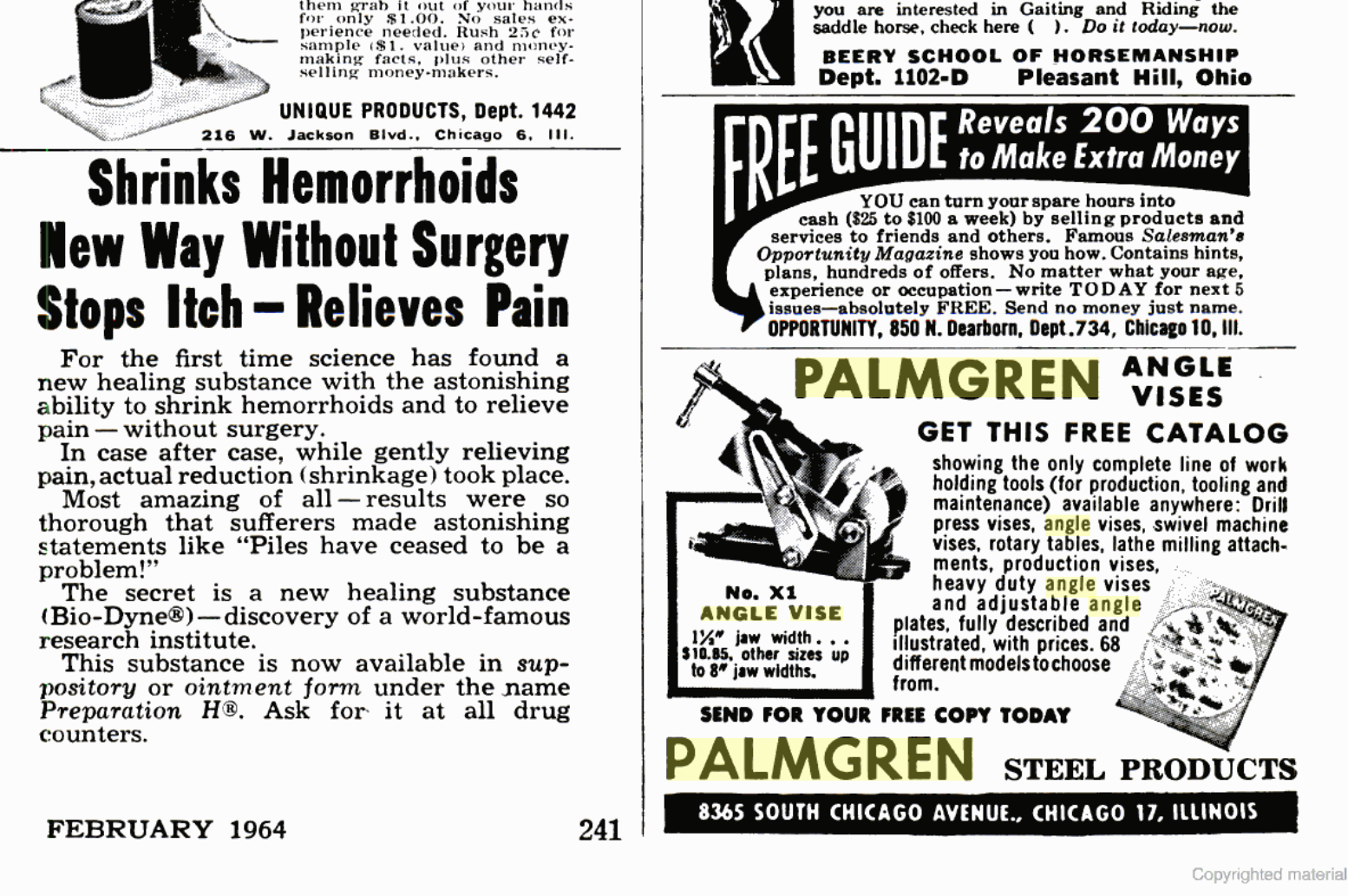

I found this 1964 Palmgren angle vise on ebay a few years ago. Cleaned it up and it has been a favorite bench top small vise. I use it with

fabricated thin lead vise jaw inserts that are quite handy to secure small gun parts. Apologies in advance for accompanying hemorrhoid solution advertisement.

fabricated thin lead vise jaw inserts that are quite handy to secure small gun parts. Apologies in advance for accompanying hemorrhoid solution advertisement.

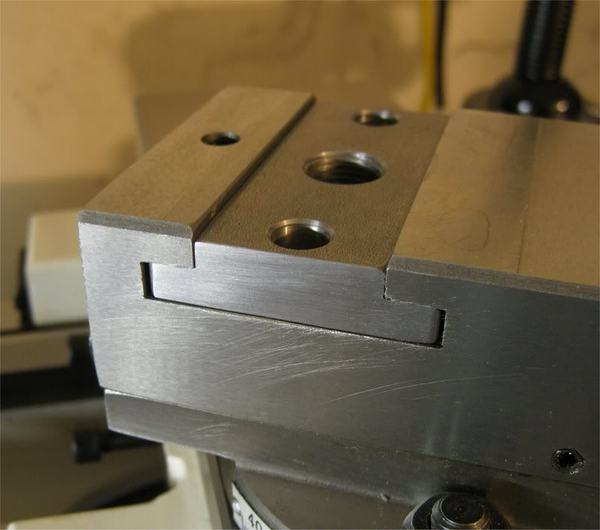

Actually sold one like that with the mill. I need the Z axis travel though, so it needs to have a leadscrew like the ones above.

Haven't owned or used a milling attachment on a lathe, but I don't see it as being well suited for drilling precision holes.

Maybe add an X/Y table to your drill press? I'm thinking it would be much easier to indicate the workpiece with that setup.

Essentially the same as using a mill; you're drilling (and not milling)- no side load on the spindle.

Maybe add an X/Y table to your drill press? I'm thinking it would be much easier to indicate the workpiece with that setup.

Essentially the same as using a mill; you're drilling (and not milling)- no side load on the spindle.

Similar threads

- Replies

- 20

- Views

- 2K

- Replies

- 35

- Views

- 7K

- Replies

- 142

- Views

- 17K

- Replies

- 20

- Views

- 5K