D

Deleted member 113831

Guest

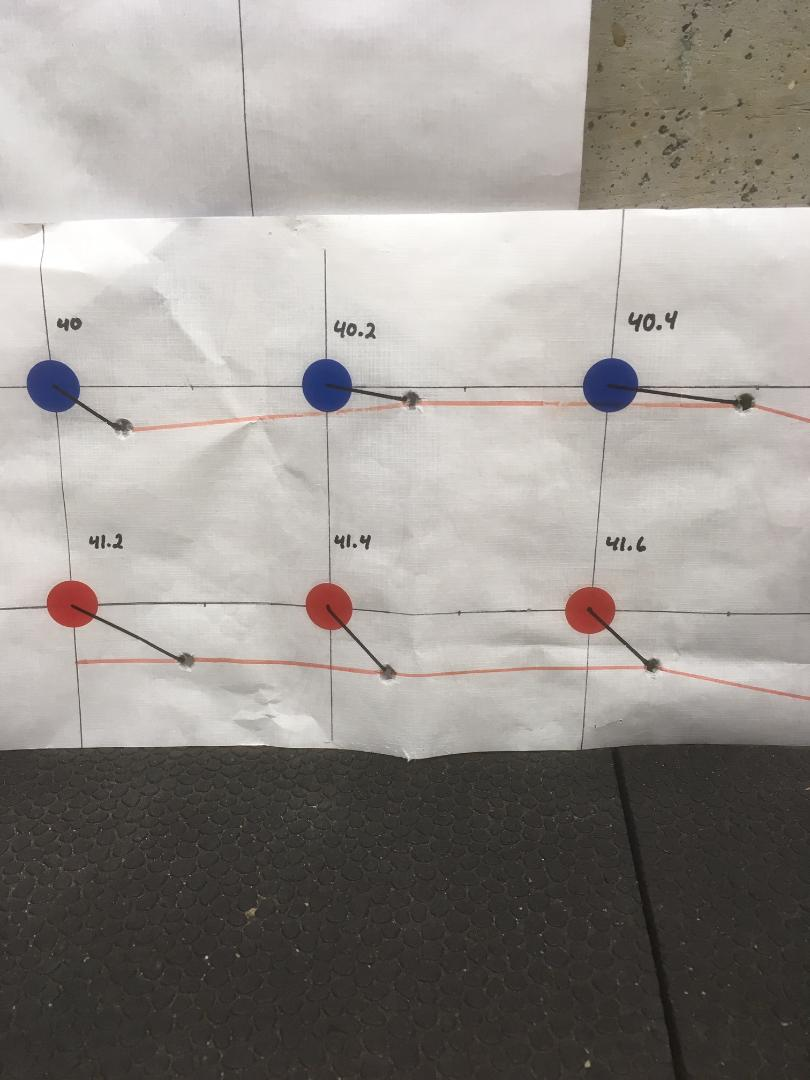

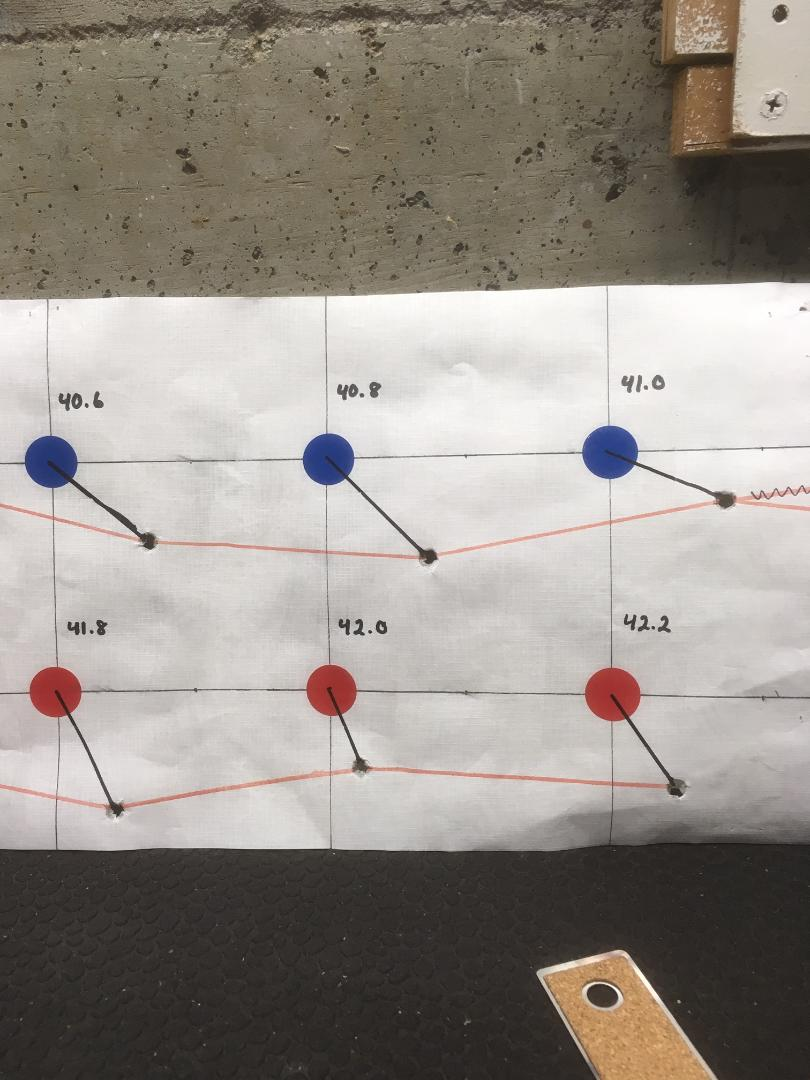

308 Winchester

175 Nosler RDF OAL 2.8"

IMR 4895 Loading from 40 grains to 42.4 grains (0.2 grain increments)

Fed 210 primer

LC brass weighing 172gr - 176.4gr

Brass is once fired, annealed, then sized, swaged, and trimmed. Not cleaned, residue in necks.

Conditions: Sunny, 1000 hrs - 1200 hrs, 50*F

Objective: Attempt to develope a load without the initial use of a chronograph at 100 yards distance.

Method: Load charges in 0.2 grain increments and look for a place where there is an apparent "flat spot" in barrel movement. This is simiar to what is done in an OCW type test, but with a single round at each charge. This is very similar to the Audette method of ladder testing, but is done at 100 yards in a horizontal orientation rather than a vertical one.

Hypothosis: The barrel will exhibit a classic sine wave pattern that will exhibit an area where the barrel movement is minimal.

175 Nosler RDF OAL 2.8"

IMR 4895 Loading from 40 grains to 42.4 grains (0.2 grain increments)

Fed 210 primer

LC brass weighing 172gr - 176.4gr

Brass is once fired, annealed, then sized, swaged, and trimmed. Not cleaned, residue in necks.

Conditions: Sunny, 1000 hrs - 1200 hrs, 50*F

Objective: Attempt to develope a load without the initial use of a chronograph at 100 yards distance.

Method: Load charges in 0.2 grain increments and look for a place where there is an apparent "flat spot" in barrel movement. This is simiar to what is done in an OCW type test, but with a single round at each charge. This is very similar to the Audette method of ladder testing, but is done at 100 yards in a horizontal orientation rather than a vertical one.

Hypothosis: The barrel will exhibit a classic sine wave pattern that will exhibit an area where the barrel movement is minimal.

Last edited by a moderator: