It's okay, He welded it to the concrete. It's not going anywhere. I'd be more worried about not having the appropriate "too much" farm epoxy not put over that whole thing.Those are some nice beads, but the weld torqued the plate on the right way up. What about clamping the pieces down?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maggie’s Motivational Pic Thread v2.0 - - New Rules - See Post #1

- Thread starter Snake-Eyes

- Start date

-

- Tags

- motivational pictures

How is the body? Rust costs $$, the rest is easy to fix.

I can't be the only one who heard, Forgive me father for i have sinned.....

Is that a real app? I gotta get that if so

its WTForecast, turn off “safe” forecast and theres some really funny forecasts that are def not for kids.Is that a real app? I gotta get that if so

Let’s see yours!Congratulations, that looks like shit.

Just downloaded it. That shit is funnyits WTForecast, turn off “safe” forecast and theres some really funny forecasts that are def not for kids.

And the forecasts are just as accurate as everyone else.Just downloaded it. That shit is funny

If you have been welding since '96 you should atleast know 7018 needs clean surfaces. You should also know how to mitigate warping plates, like a temporary gusset or running 3/32 or 1/8 rod to lower heat input, or anchoring it to what it is sitting on.On an engine driven welding machine (Bobcat 250) and in a 10 mph wind.

Been welding since 1996. Have not heard "looks like shit" since that year.

You should also know that same heat destroys the concrete you just welded on. For a dirty pipe and a dirty plate it looks okish. I would rather weld low H rod outside than through dirty shit and call it a cover pass which means your 6010 root looks like garbage, because of that was a structural weld your plate with a 3/4" gap between the bearing surface and your 4" pipe means 7/8s of that bearing structure is useless; shouldve used 2x2x1/8 angle for that much support. It looks like shit. Welds look meh..

I tried to read this. I really did. All I got was “I have technical knowledge. I need to show it and to shit on someone not in the industry I am opining on.” After I figured that out the rest of it lost credibility.If you have been welding since '96 you should atleast know 7018 needs clean surfaces. You should also know how to mitigate warping plates, like a temporary gusset or running 3/32 or 1/8 rod to lower heat input, or anchoring it to what it is sitting on.

You should also know that same heat destroys the concrete you just welded on. For a dirty pipe and a dirty plate it looks okish. I would rather weld low H rod outside than through dirty shit and call it a cover pass which means your 6010 root looks like garbage, because of that was a structural weld your plate with a 3/4" gap between the bearing surface and your 4" pipe means 7/8s of that bearing structure is useless; shouldve used 2x2x1/8 angle for that much support. It looks like shit. Welds look meh..

Other than paint, should work in the Ukraine.Any welding pointers?

Thats fine. I actually have nothing to show, but that weld is like bragging on picking up one of DirtyD's girls last night. You got some yeah, but it ain't good. I am worried about this guys machine if he welds 5/32 7018 alot on a 250 Bobcat, but then its getting technical.I tried to read this. I really did. All I got was “I have technical knowledge. I need to show it and to shit on someone not in the industry I am opining on.” After I figured that out the rest of it lost credibility.

I’ll zip tie a tweco gun to my dick and show you some crispier welds than that.

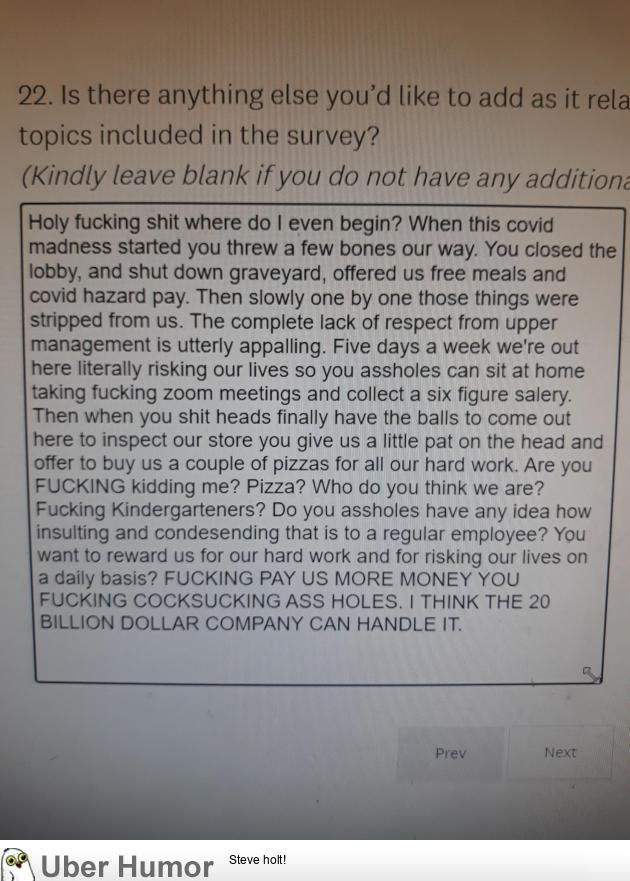

Is this real?

Please God, let this be real…

This is why we should be thinking about sending arms to the Ukrainians.

apparently its satire, but wouldnt it be fucking amazing if it happenedIs this real?

Please God, let this be real…

Can I send this to HR?

Lots of other hippie protest music to listen to. As Ronnie said, " don't need him around anyhow."

Skoda car ad

Need more car ads like this (Press unmute) | uberHumor.com

uberHumor.com: Probably the funniest site on the net...

uberhumor.com

The late "Popcorn" Sutton? I did not realize he was so "philosophical." He was considered one of the most prolific moonshiners in the community.

Similar threads

- Replies

- 0

- Views

- 41K