I picked up a used AIAX here on the hide that came with both a 6mm Creedmoor and 308 barrel. I decided I'd shoot the 6 Creed for the couple of 1000 yard benchrest shoots I am able to make it to this year.

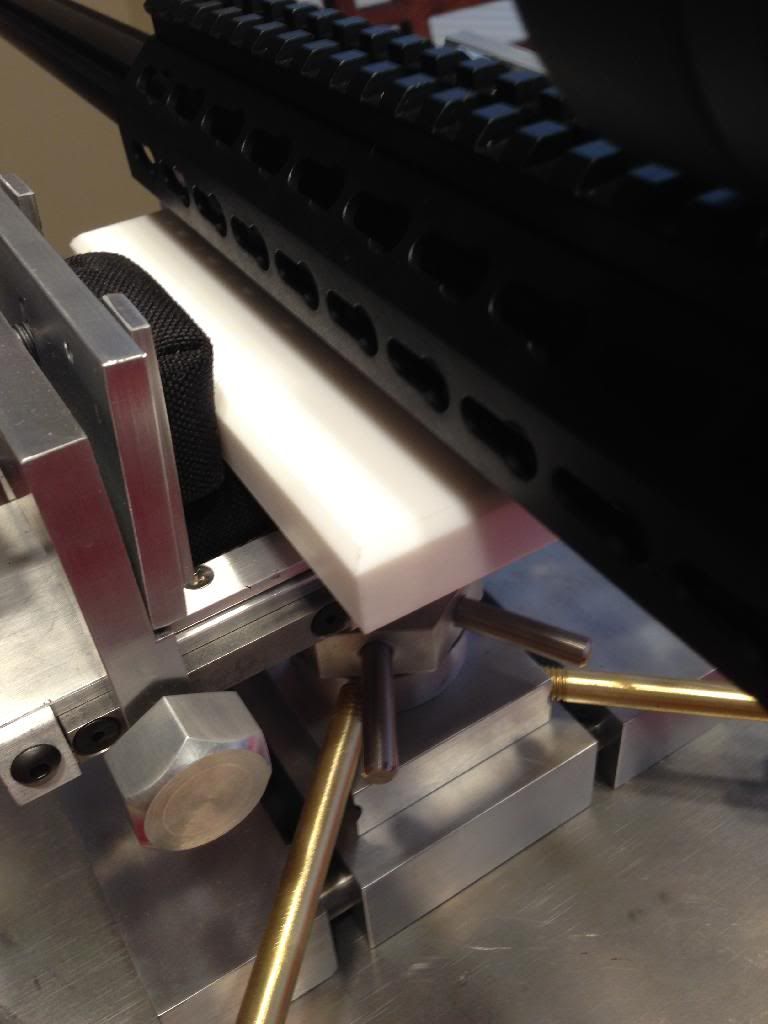

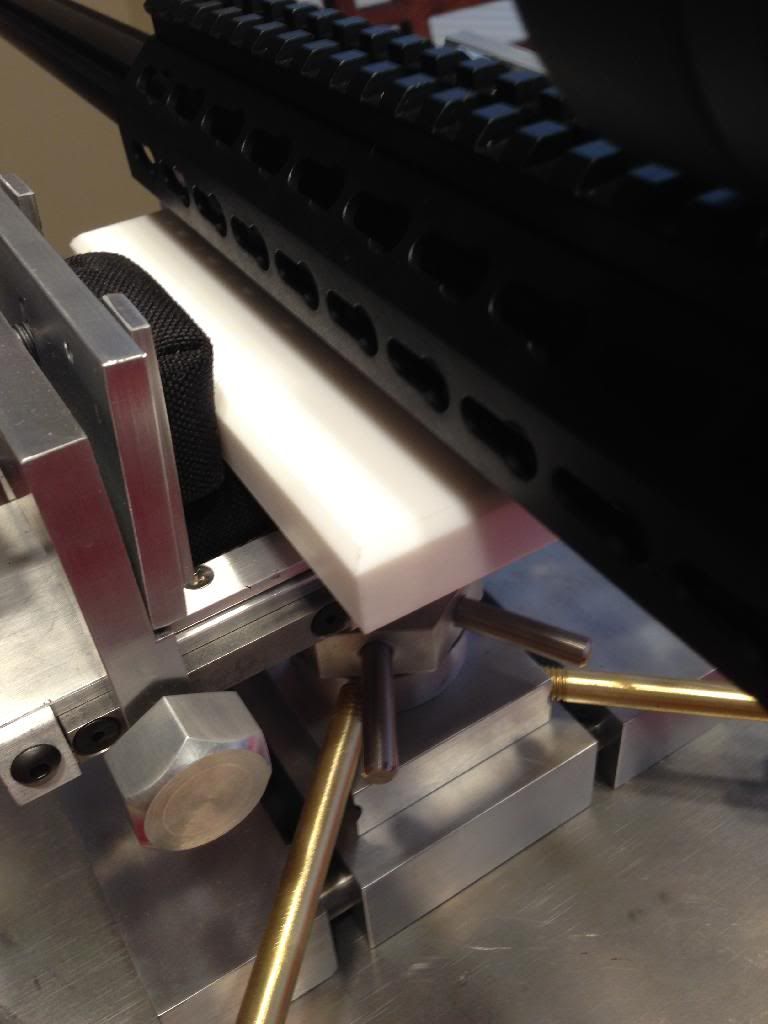

So it rides my rest properly, I built a forend skid plate and thought I'd share.

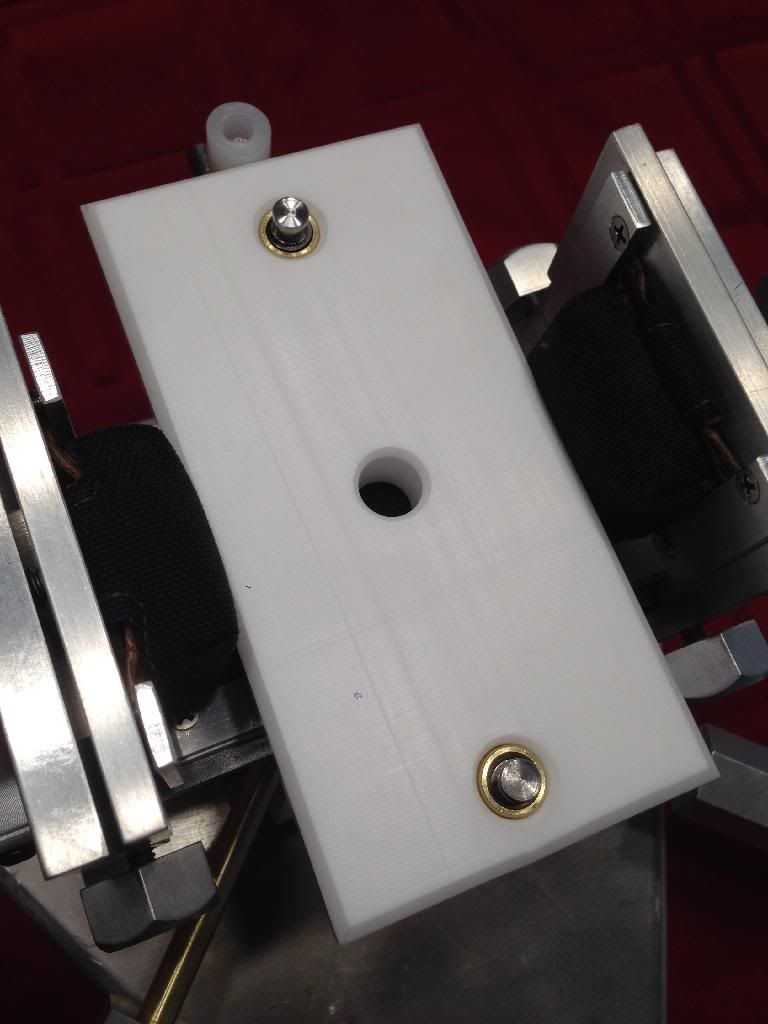

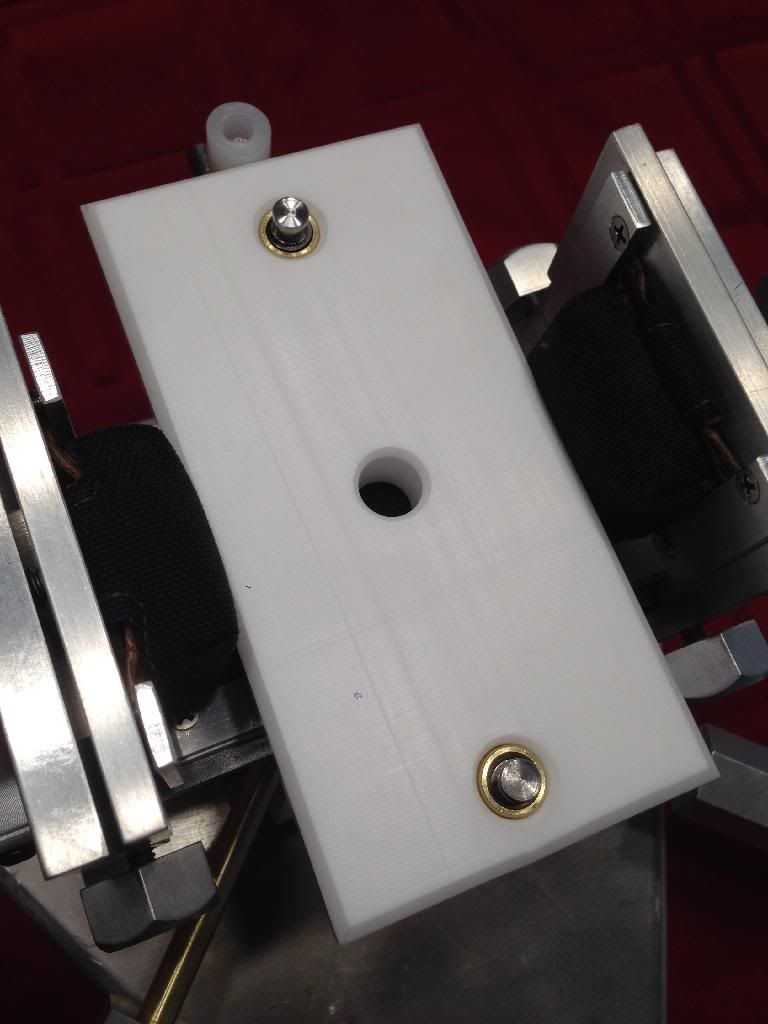

I started with a piece of 3/4" virgin PTFE teflon, I used standard woodworking tools (table saw, planer, joiner, router, etc) to get the dimensional shape I wanted or 3" x 6" ~5/8" thick.

I then proceeded to look for threaded inserts that will work with the AI supplied M8 LH attachment screws. I spent too much time looking for these and can say they don't exist.

This forced me to create my own attachement screws. I started with 3/8-16 x 1" set screws (they had the minor dimension needed for the flange) and machined them to match the AI M8 screws. The only thing that I'd change in hindsight is I'd have kept a few more threads at the top as the inserts I used don't bring threads flush to the bottom of the teflon. I do have adequate thread engagement when the skid plate is installed, but I have lots of room and wouldn't have minded using it for more engagement.

I drilled the teflon for 3 inserts to use 3 screws as attachment points, but my local fastener shop only had 2 inserts in stock. Based on what I see I'm happy with the 2 and probably won't bother getting a 3rd insert installed.

In the end, it works very well. I have a nice slick surface due to the low co-efficient of friction of the teflon and rest bag, it seems to run true and is well attached. I still need to figure out what to do with the stock so that it rides a rear bag as well as it rides the front rest. I thinking I'll use the rear butt spike hole as a mounting point for something, I'm just not sure what "something" is at this point. It will come to me over time, I need to take the skins off and see what there is to work with.

Here are a few photos of the finished project.

So it rides my rest properly, I built a forend skid plate and thought I'd share.

I started with a piece of 3/4" virgin PTFE teflon, I used standard woodworking tools (table saw, planer, joiner, router, etc) to get the dimensional shape I wanted or 3" x 6" ~5/8" thick.

I then proceeded to look for threaded inserts that will work with the AI supplied M8 LH attachment screws. I spent too much time looking for these and can say they don't exist.

This forced me to create my own attachement screws. I started with 3/8-16 x 1" set screws (they had the minor dimension needed for the flange) and machined them to match the AI M8 screws. The only thing that I'd change in hindsight is I'd have kept a few more threads at the top as the inserts I used don't bring threads flush to the bottom of the teflon. I do have adequate thread engagement when the skid plate is installed, but I have lots of room and wouldn't have minded using it for more engagement.

I drilled the teflon for 3 inserts to use 3 screws as attachment points, but my local fastener shop only had 2 inserts in stock. Based on what I see I'm happy with the 2 and probably won't bother getting a 3rd insert installed.

In the end, it works very well. I have a nice slick surface due to the low co-efficient of friction of the teflon and rest bag, it seems to run true and is well attached. I still need to figure out what to do with the stock so that it rides a rear bag as well as it rides the front rest. I thinking I'll use the rear butt spike hole as a mounting point for something, I'm just not sure what "something" is at this point. It will come to me over time, I need to take the skins off and see what there is to work with.

Here are a few photos of the finished project.