A Buddy of mine stopped by today while I was checking some 308's for Concentricity. He liked the way I was doing it and was pissed that he paid $90 for his after seeing mine! All I do is use my LE Wilson trimmer base and Case Trimmer holder to spin it on the base! I picked up Magnetic Base From Harbor freight and use a dial style gage! I screwed a piece of steel bar stock to my bench to attached the base to. You can move the magnetic base anywhere you want it and just flick the switch to on and it's stuck in place.

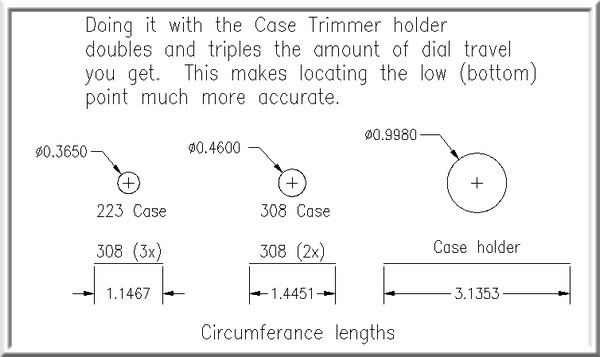

I really like doing it this way. The LE Wilson case trimmer holder holds it perfect and gives me a bigger area to turn the case. I used to have a Sinclair Concentricity gage but use this method only now!

If you currently have a Wilson trimmer this is a really good setup for checking run-outs.

Terry

<object width="425" height="350"> <param name="movie" value="http://www.youtube.com/v/oD1SFalhazg"></param> <param name="wmode" value="transparent"></param> <embed src="http://www.youtube.com/v/oD1SFalhazg" type="application/x-shockwave-flash" wmode="transparent" width="425" height="350"> </embed></object>

I really like doing it this way. The LE Wilson case trimmer holder holds it perfect and gives me a bigger area to turn the case. I used to have a Sinclair Concentricity gage but use this method only now!

If you currently have a Wilson trimmer this is a really good setup for checking run-outs.

Terry

<object width="425" height="350"> <param name="movie" value="http://www.youtube.com/v/oD1SFalhazg"></param> <param name="wmode" value="transparent"></param> <embed src="http://www.youtube.com/v/oD1SFalhazg" type="application/x-shockwave-flash" wmode="transparent" width="425" height="350"> </embed></object>