That I built myself.

It started out as a 700 LTR in 308 that I bought used probably 18 years ago now. I left it stored improperly and unused for several years and the bore rusted. Not terrible, still shootable, but it was doing strange things at distance and it was time for the original 12 twist to go anyway.

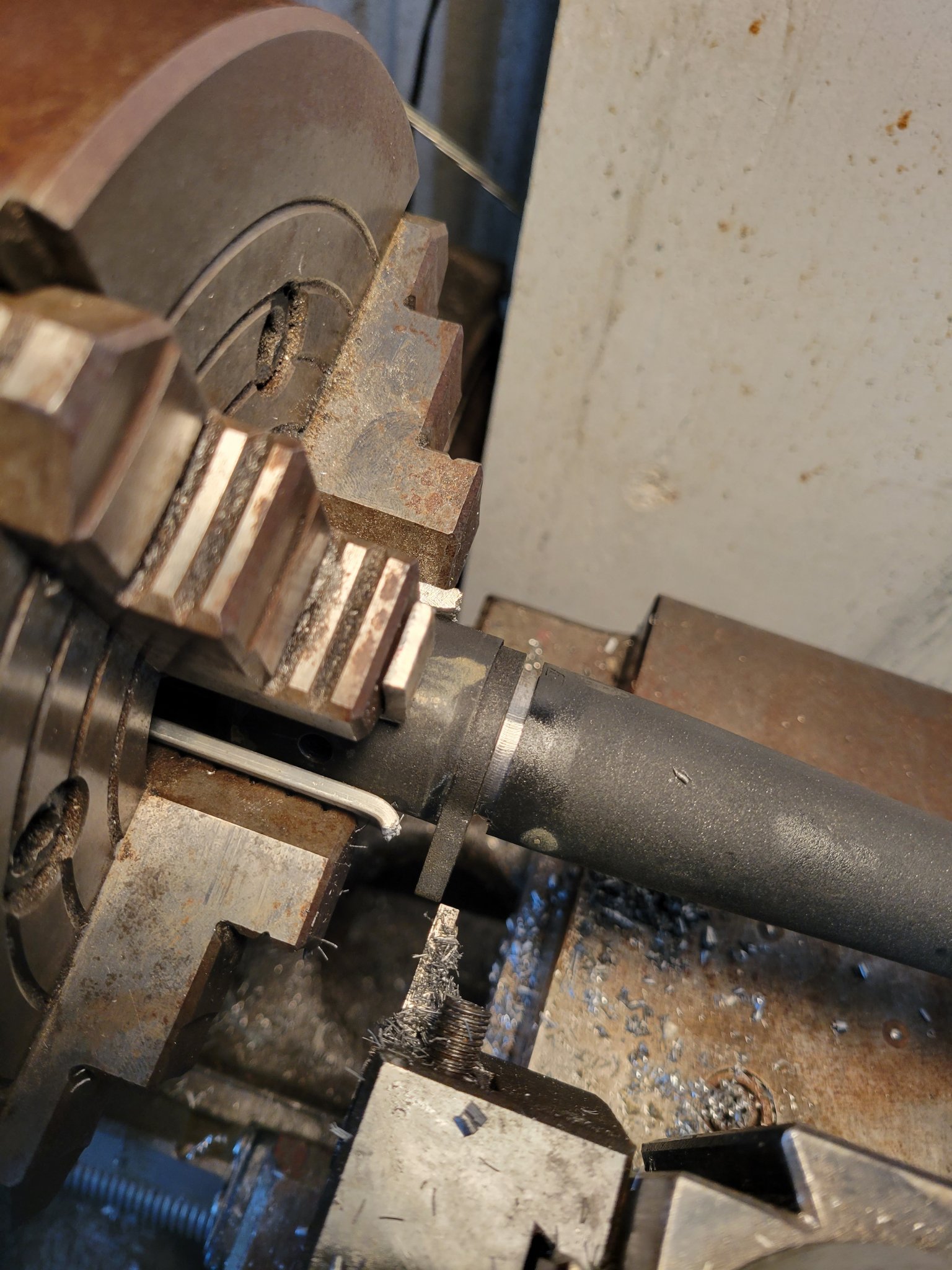

Factory tube removed.

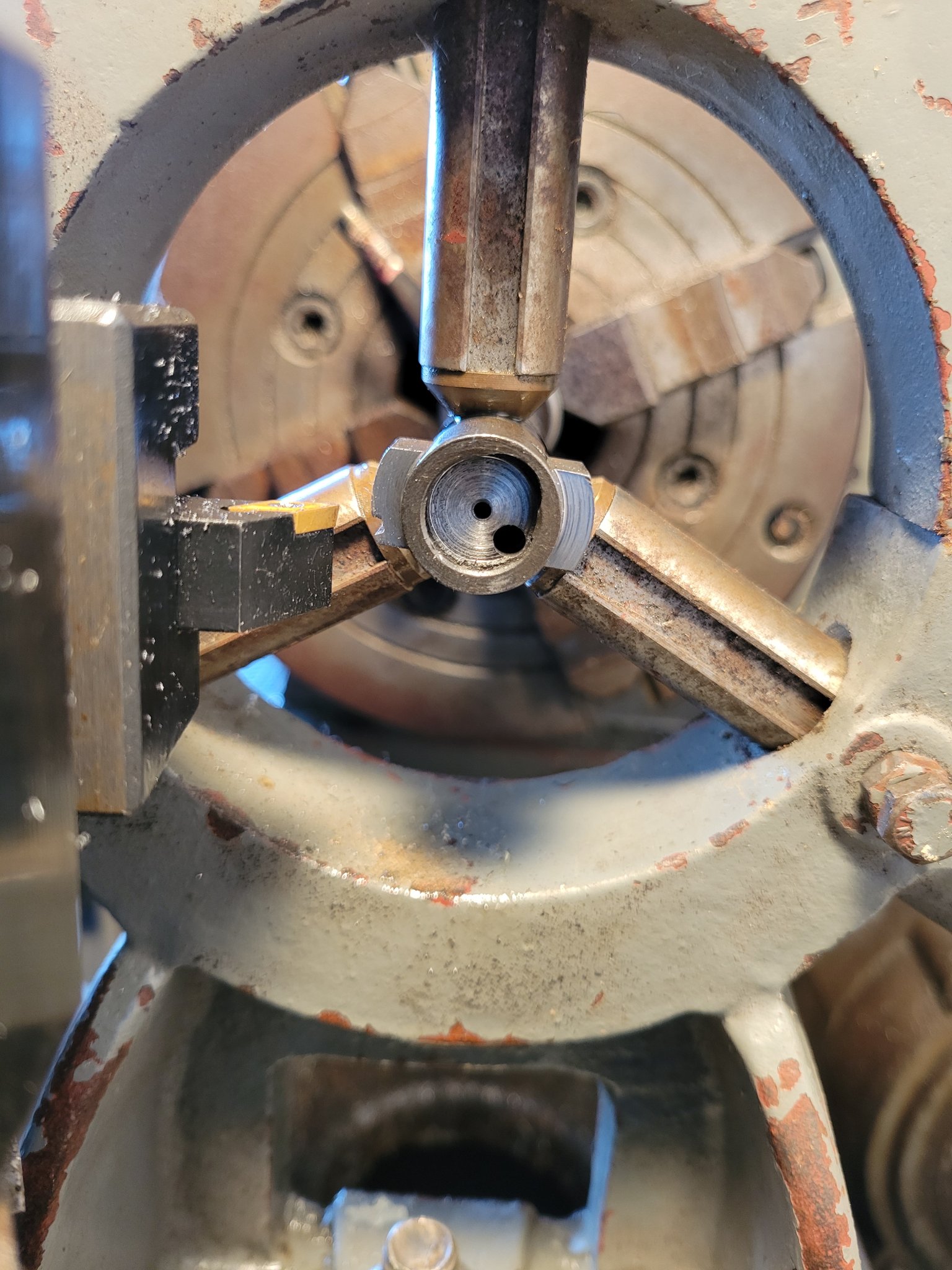

Mandrel that I made to square the reciever face. This was turned for a pretty snug fit to the bore of the reciever.

Setup and squaring the face.

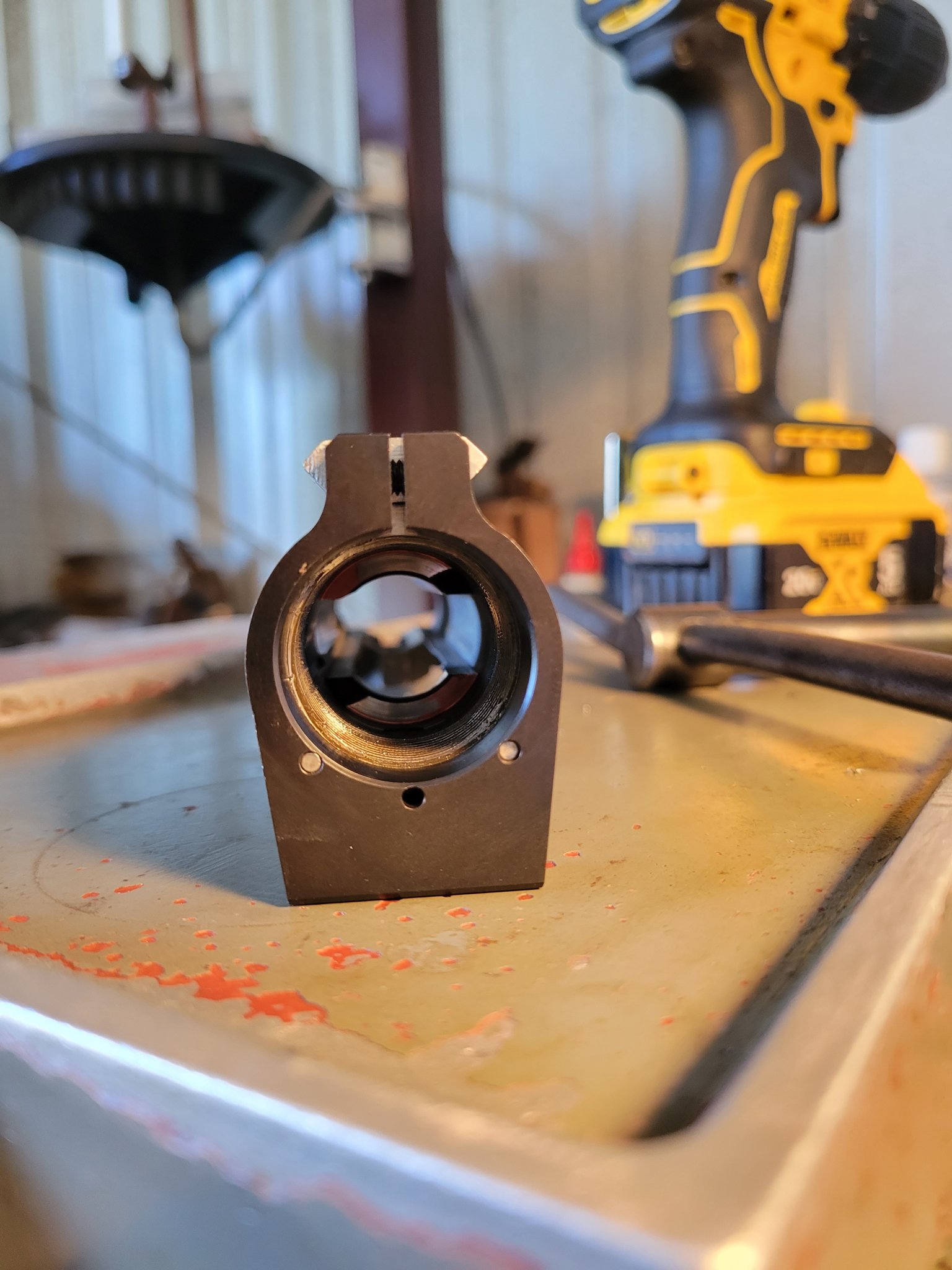

I made this to square up the lugs in the reciever. Some adhesive backed sandpaper on it. Started with 600 and finished with 1000 grit

Finished product.

WTO switchlug pinned to the reciever.

Setup and trued the bolt face.

On to the barrel. This was a used barrel that was pulled off of my 300winmag at 185 rounds. A whole other story. Barrel was still in good shape, didn't even show any fire cracking in the throat yet. Still had enough shank that I had room to part off 2" where the old chamber was.

It's a 1:9 twist lilja.

Tennon threaded, bolt nose recess finished, and a slight 29 degree bevel to aid in feeding. Ready to start chambering. I chambered it with an m852 match reamer from Manson.

Muzzle tennon threaded 5/8-24. This was an awkward setup I wasn't really fond of but it did the job. I finished this barrel at 20" and the headstock on my lathe is too long with the 4 jaw to be able to set it up with the spider on the back end.

I dialed the breech end in in the chuck and used a live center in the muzzle to turn the 5/8" major od, then set that up in the steady rest. After that was set up I cleaned up and crowned the muzzle. Failed to get a pic of that. Then I used a crown saver on the live center and cut the threads.

Then I had to re bed the action as the WTO recoil lug is much thicker than the factory lug. This is my second bedding job and it was a much better experience than my first. Lol.

I used brownells steelbed and black shoe polish for a release agent. It's what I had at the moment. There was no way I was using the stuff they include in the kit again. That was the bad experience the first time.

Now for the bad part. At some point in the chambering process, the reamer chattered ever so slightly. I never felt, or heard, anything to indicate that had happened, but apparently it did. You can kind of see it in the pictures. Looks kind of like a crown shaped. They're not really deep, but you can feel them on fired cases.

For my reamer holder I made rigid reamer holder modeled after a video I watched from ultimate reloader. It didn't come out as precise as I would have like but it was by no means a sloppy fit on the reamer.

When I tighted the set screw to hold the reamer, there was a couple thousandths movement at the tip of the reamer. So, my solution to this (instead of just ordering a reamer holder) was just just run the set screw in enough to keep the reamer from spinning. I know the hole in the holder I made was as close to center line as it could be so I didn't think it would cause a problem. Not sure if that caused the chatter or not.

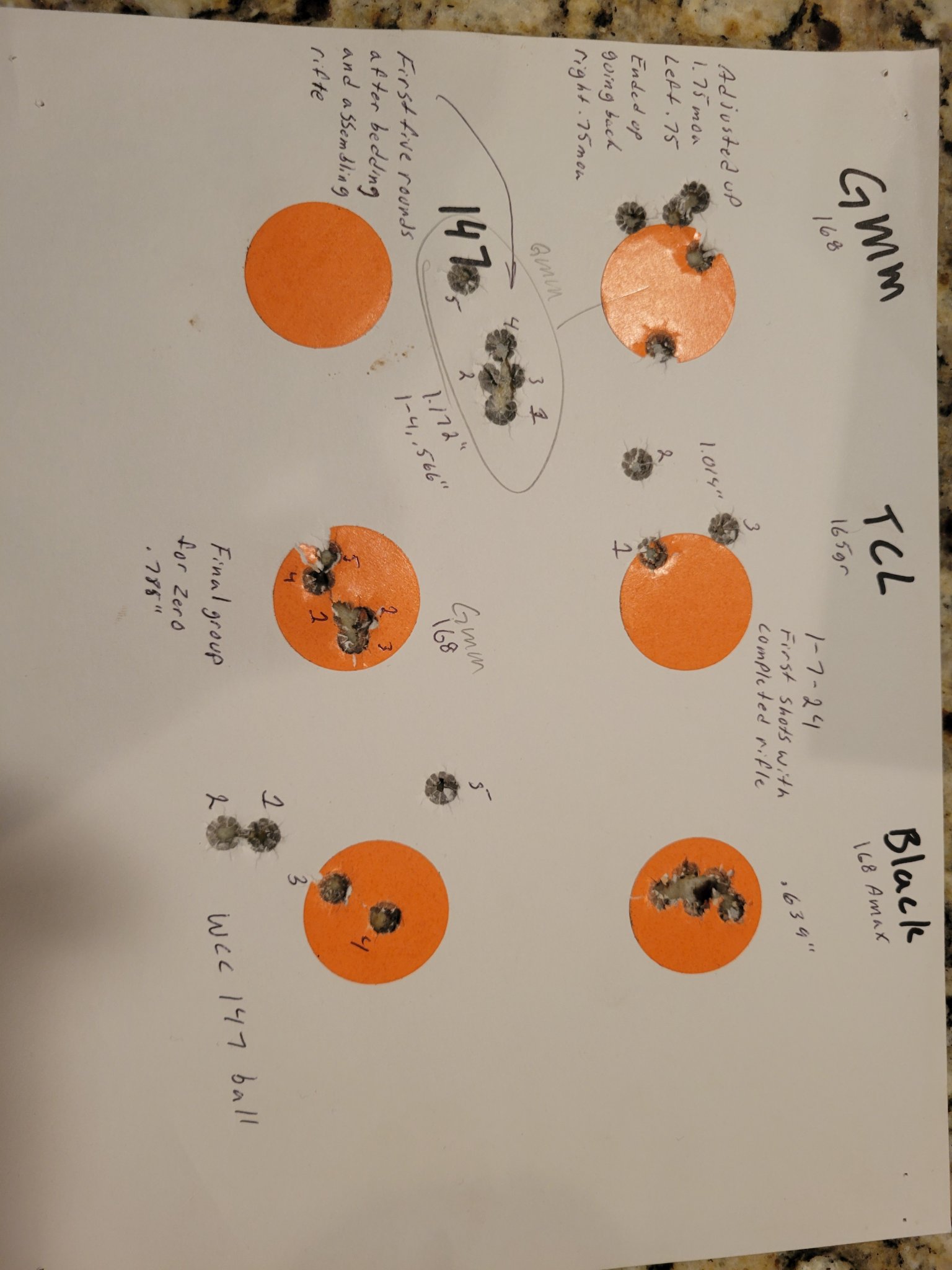

But it does shoot. Nothing hit the target sideways lol. There's a part of me that will always wonder if it could be better though. That chamber will probably bug me forever. I've thought about ordering a floating holder from Manson and setting the barrel back one thread to see if it would clean up.

It started out as a 700 LTR in 308 that I bought used probably 18 years ago now. I left it stored improperly and unused for several years and the bore rusted. Not terrible, still shootable, but it was doing strange things at distance and it was time for the original 12 twist to go anyway.

Factory tube removed.

Mandrel that I made to square the reciever face. This was turned for a pretty snug fit to the bore of the reciever.

Setup and squaring the face.

I made this to square up the lugs in the reciever. Some adhesive backed sandpaper on it. Started with 600 and finished with 1000 grit

Finished product.

WTO switchlug pinned to the reciever.

Setup and trued the bolt face.

On to the barrel. This was a used barrel that was pulled off of my 300winmag at 185 rounds. A whole other story. Barrel was still in good shape, didn't even show any fire cracking in the throat yet. Still had enough shank that I had room to part off 2" where the old chamber was.

It's a 1:9 twist lilja.

Tennon threaded, bolt nose recess finished, and a slight 29 degree bevel to aid in feeding. Ready to start chambering. I chambered it with an m852 match reamer from Manson.

Muzzle tennon threaded 5/8-24. This was an awkward setup I wasn't really fond of but it did the job. I finished this barrel at 20" and the headstock on my lathe is too long with the 4 jaw to be able to set it up with the spider on the back end.

I dialed the breech end in in the chuck and used a live center in the muzzle to turn the 5/8" major od, then set that up in the steady rest. After that was set up I cleaned up and crowned the muzzle. Failed to get a pic of that. Then I used a crown saver on the live center and cut the threads.

Then I had to re bed the action as the WTO recoil lug is much thicker than the factory lug. This is my second bedding job and it was a much better experience than my first. Lol.

I used brownells steelbed and black shoe polish for a release agent. It's what I had at the moment. There was no way I was using the stuff they include in the kit again. That was the bad experience the first time.

Now for the bad part. At some point in the chambering process, the reamer chattered ever so slightly. I never felt, or heard, anything to indicate that had happened, but apparently it did. You can kind of see it in the pictures. Looks kind of like a crown shaped. They're not really deep, but you can feel them on fired cases.

For my reamer holder I made rigid reamer holder modeled after a video I watched from ultimate reloader. It didn't come out as precise as I would have like but it was by no means a sloppy fit on the reamer.

When I tighted the set screw to hold the reamer, there was a couple thousandths movement at the tip of the reamer. So, my solution to this (instead of just ordering a reamer holder) was just just run the set screw in enough to keep the reamer from spinning. I know the hole in the holder I made was as close to center line as it could be so I didn't think it would cause a problem. Not sure if that caused the chatter or not.

But it does shoot. Nothing hit the target sideways lol. There's a part of me that will always wonder if it could be better though. That chamber will probably bug me forever. I've thought about ordering a floating holder from Manson and setting the barrel back one thread to see if it would clean up.