Recently moved, but unfortunately, we downsized and the reloading room got axed. Has anyone managed to set up a "mobile" single-stage press? something that I could put on my desk that isn't permanently mounted, or doesn't modify the desk? I know plenty of people use arbor presses, but how are they processing brass? My other option is using a shed but the one we have is unheated and reloading in 17-degree weather doesn't exactly entice me right now.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Having trouble using the site?

Contact support

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New house, no reloading room

- Thread starter Outcome

- Start date

Mount it to 3/4 plywood x2 thickness, c-clamp to the desk/table.

I mount my presses to a bench grinder stand from harbor freight. Never liked have the press on the same work surface as my scales.

Bolts and wing nuts. Makes it easy to put on the coffee table and then remove when you’re done. Mines in the converted garage but if I move I’ll do the same thing in the living room.

(Don’t say shit about what I have playing, I’ve seen everything else)

(Don’t say shit about what I have playing, I’ve seen everything else)

Not gay porn, you are good.Bolts and wing nuts. Makes it easy to put on the coffee table and then remove when you’re done. Mines in the converted garage but if I move I’ll do the same thing in the living room.

View attachment 7564625

(Don’t say shit about what I have playing, I’ve seen everything else)

I use the Frankford Armory Platinum Reloading Stand, and an Inline Fabrication Flush Mount Quick Change Base. It's an awesome combination and the whole thing disassembles in 2 minutes and folds into a small storage space. Here are photos with the press mounted, and removed (by two wing-nuts).

I set it up in a closet. Stows completely away. I have a fold down “floor” to catch stray powder from the carpet. This is a standard bedroom clothes closet. The Lowe’s generic counter top is on a frame that is lag bolted into the studs rock solid

thats awesome!!I set it up in a closet. Stows completely away. I have a fold down “floor” to catch stray powder from the carpet. This is a standard bedroom clothes closet. The Lowe’s generic counter top is on a frame that is lag bolted into the studs rock solid View attachment 7564680View attachment 7564682View attachment 7564684

Unfortunately putting holes into the coffee table would put me in the dog house with the wife haha. The issue isn't a table, I still have my workbench from the last house, it's mostly space. Which sucks.

Have you done that? Does it work well? I like it.Mount it to 3/4 plywood x2 thickness, c-clamp to the desk/table.

Thats awesome, I love the fold-down floor.I set it up in a closet. Stows completely away. I have a fold down “floor” to catch stray powder from the carpet. This is a standard bedroom clothes closet. The Lowe’s generic counter top is on a frame that is lag bolted into the studs rock solid View attachment 7564680View attachment 7564682View attachment 7564684

Unfortunately putting holes into the coffee table would put me in the dog house with the wife haha. The issue isn't a table, I still have my workbench from the last house, it's mostly space. Which sucks.

Have you done that? Does it work well? I like it.

With the right c clamps it will work. Move to the corner, 2 in front as deep in as you can go. 1 in the rear as close to center as you can get.

Assuming normal resizing regular calibers. Imperial paste wax is your friend. Bullet seating no problem.

Some guys will take a set up like this to the range as well.

Single stage press with minimal space / mobile is all I've had for years. I do have the RCBS Rock chucker press but I have mainly used Wilson dies and an arbor press. The Rock chucker press was either bolted to a workbench or a piece of plywood that can be clamped somewhere.

RCBS hand primer, Forster case trimmer, Wilson dies, arbor press, clamps, RCBS powder thrower, digital scale, Case Prep tool, calipers, components in various other tools can be all put in a plastic tote.

years ago we were allowed to reload at the bench so we learn to carry Only what was necessary. A rawhide or weighted plastic Mallet worked great for next sizing and decapping.

RCBS hand primer, Forster case trimmer, Wilson dies, arbor press, clamps, RCBS powder thrower, digital scale, Case Prep tool, calipers, components in various other tools can be all put in a plastic tote.

years ago we were allowed to reload at the bench so we learn to carry Only what was necessary. A rawhide or weighted plastic Mallet worked great for next sizing and decapping.

Just do it and see if she notices.Unfortunately putting holes into the coffee table would put me in the dog house with the wife haha. The issue isn't a table, I still have my workbench from the last house, it's mostly space. Which sucks.

Have you done that? Does it work well? I like it.

Or just mount it to a board that you can easily c clamp down to any surface. I use to do that in the kitchen island. But the couch is comfier than then bar stools.

But if you don’t have room for the work bench then I’m not really sure how you still having it is possible? Just set it somewhere?

Still, based on the movie I think he's probably seen one up close. Just sayin'.Not gay porn, you are good.

This guy had all these pull out boxes in his truck, full mobile gunsmith type shit and reloading gear. Press bolted to the tailgate, vise on other side. He literally had everything I'd have in my garage in his truck at the range. Wanna say he had a Dillon and Forster? He was best friends with our Bde. commander so he was always at our SDM ranges (where his truck of tricks came in handy a few times!).With the right c clamps it will work. Move to the corner, 2 in front as deep in as you can go. 1 in the rear as close to center as you can get.

Assuming normal resizing regular calibers. Imperial paste wax is your friend. Bullet seating no problem.

Some guys will take a set up like this to the range as well.

I'm not sure that's how I'd wanna roll.

I've seen another setup where the guy just had a single stage bolted down and what looked like his older gear he'd bring to the range. All basic manual type gear. I think one day I may do this, his workup time for load development was literally on the spot. No wasting shit or trial and error, rinse repeat, multiple trips to the range either.

A shed --not a cheap metal one but pour a pad and build a small room. Run power and heat it with one of those electric oil heaters. You'll be fine.

I had to stop using a TV while loading, just too easy to make tiny mistakes. Too distracting. Plus I'm afraid some of them will turn me gay and I'll wind up loading in my LR while watching old chick flix too!

Just an idea, but you COULD make a heavy duty foot locker to keep everything in and have it so you can bolt the press on top. Put wheels on it and you can roll it away in the corner, put a table cloth and lamp on it and now it's furniture...

LMAO, I'm out.Still, based on the movie I think he's probably seen one up close. Just sayin'.

My first reloading bench was an old wooden ammo crate, stood on end, probably 2'x2'x3'. Mounted the press on it and put a shelf in it to store everything else.

My press is also on a bench grinder stand.I mount my presses to a bench grinder stand from harbor freight. Never liked have the press on the same work surface as my scales.

Very elegant!I set it up in a closet. Stows completely away. I have a fold down “floor” to catch stray powder from the carpet. This is a standard bedroom clothes closet. The Lowe’s generic counter top is on a frame that is lag bolted into the studs rock solid View attachment 7564680View attachment 7564682View attachment 7564684

It might as well been, it's fucking Mystic Pizza, come on Spife..

Not gay porn, you are good.

You sound awfully familiar with it!It might as well been, it's fucking Mystic Pizza, come on Spife..

Now I’m off to that Kidman-Jackman movie: Australia. So far it’s like The Proposition but less respectable.

Actually friend, I can't remember ever watching it, and if I did, I'd never tell.. Lol..You sound awfully familiar with it!

I used 2x4, 18" long to mount a lee turret press. I made this for the shooting range/camping(never did it) , then used it at the kitchen table. Works well. I mainly use it in a bench vise.With the right c clamps it will work. Move to the corner, 2 in front as deep in as you can go. 1 in the rear as close to center as you can get.

Assuming normal resizing regular calibers. Imperial paste wax is your friend. Bullet seating no problem.

Some guys will take a set up like this to the range as well.

I bought a harbor freight bench grinder stand and got two 24x24x1 pieces of plywood which I glued and screwed and together. Bolted the wood to the grinder stand and used that in the small laundry room in the apartment days. I always left the wood attached to the stand but you could always take it off and stash it somewhere for easier storage.

I just have to say, that's impressive.I set it up in a closet. Stows completely away. I have a fold down “floor” to catch stray powder from the carpet. This is a standard bedroom clothes closet. The Lowe’s generic counter top is on a frame that is lag bolted into the studs rock solid

You are a genius dude.I set it up in a closet. Stows completely away. I have a fold down “floor” to catch stray powder from the carpet. This is a standard bedroom clothes closet. The Lowe’s generic counter top is on a frame that is lag bolted into the studs rock solid View attachment 7564680View attachment 7564682View attachment 7564684

That is very impressive.

Precisionrifleblog.comYou are a genius dude.

That is very impressive.

Search "portable reloading press"

I have built 2 so far. I made a few adjustments though. I kept mine flat across the top. Used rugged structural screws instead if angle iron. Modified the cutting of one piece because of the grain direction of the wood. Cost. About $30

The prior residents of our house left behind an old water-damaged bedside table when they left. I drilled holes in the top to match my Rock Chucker, and a set of bolts and wing nuts holds it secure when in use. A pair of kettlebells in the bottom drawer keep the whole thing steady. I set it up in the dining room so I can use the table for the rest of the process. The contraption lives in the shed between uses, and the press + bolts stay in a foot locker.

Not very pretty, but it works great and cost me about $2 for the nuts and bolts.

Not very pretty, but it works great and cost me about $2 for the nuts and bolts.

Sweet set-upI set it up in a closet. Stows completely away. I have a fold down “floor” to catch stray powder from the carpet. This is a standard bedroom clothes closet. The Lowe’s generic counter top is on a frame that is lag bolted into the studs rock solid View attachment 7564680View attachment 7564682View attachment 7564684

I converted a rolling mechanics tool chest. It lives in the garage. I just roll it out when needed. Mounted 5/4 in plywood top to the lid. Top section has powder. Drawers are full of tools, dies sets, bullets etc. The Hornady LNL (9mm, 38sp, 45 ACP)is bolted to one end. Lee plate mounted in middle for single stage de-caping and turret press for low volume pistol rounds (380, 44M 45LC). Other side has a RCBS plate, for Rock Crusher, powder measure & priming tools for rifle rounds. I got it as a scratched floor model at Harbor Freight. Works great for me.

Harrells presses mount to the bench with built in C-Clamp.

Harrells presses mount to the bench with built in C-Clamp.

Put a heater, fridge and a Lazy Boy in the shed. Just save room for the perfect reloading set up.Recently moved, but unfortunately, we downsized and the reloading room got axed. Has anyone managed to set up a "mobile" single-stage press? something that I could put on my desk that isn't permanently mounted, or doesn't modify the desk? I know plenty of people use arbor presses, but how are they processing brass? My other option is using a shed but the one we have is unheated and reloading in 17-degree weather doesn't exactly entice me right now.

Seriously, my wife knows where she ranks and it is well beneath my reloading room.

I have had lots of "perfect" wives but there can only be one perfect reloading room.

+1 for the inline fabrication system. I now have a bunch of stuff (different presses, a large vise, etc) all with mounting plates. Dan is an awesome guy. If you have anything you want to mount he will make a plate for it. And he is very responsive to a direct email. Can’t say enough good things about him and his gear.

Recently moved, but unfortunately, we downsized and the reloading room got axed. Has anyone managed to set up a "mobile" single-stage press? something that I could put on my desk that isn't permanently mounted, or doesn't modify the desk? I know plenty of people use arbor presses, but how are they processing brass? My other option is using a shed but the one we have is unheated and reloading in 17-degree weather doesn't exactly entice me right now.

Harrell's press. Precision, go anywhere and do anything... even the kitchen table.

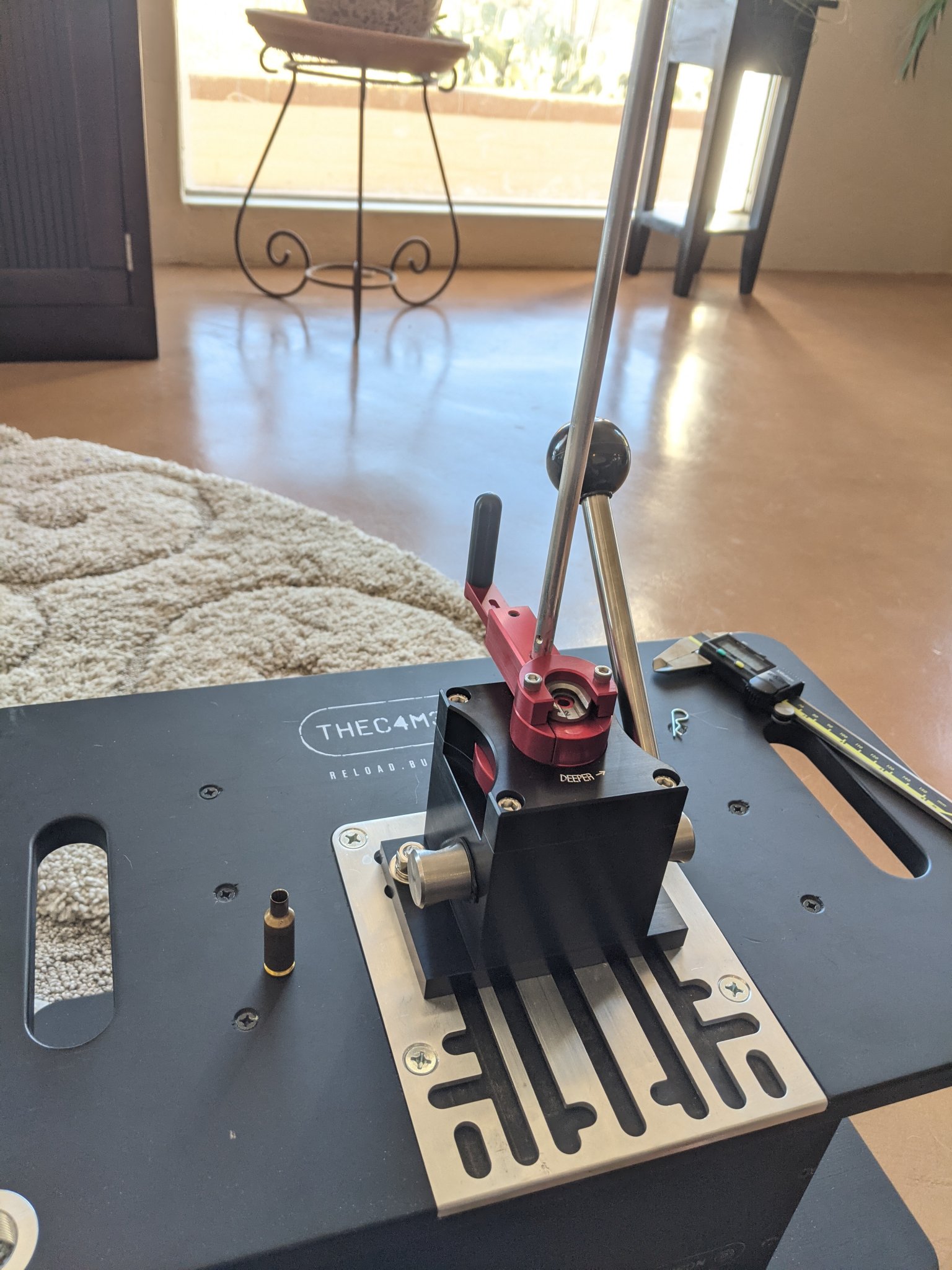

View attachment 7566429

Harrell's press. Precision, go anywhere and do anything... even the kitchen table.

I think in the long run, you get more enjoyment and use in putting heat in the shed and using that. Setting up in the house, then tearing it down over and over gets old real fast. Best of luck with it. DavidRecently moved, but unfortunately, we downsized and the reloading room got axed. Has anyone managed to set up a "mobile" single-stage press? something that I could put on my desk that isn't permanently mounted, or doesn't modify the desk? I know plenty of people use arbor presses, but how are they processing brass? My other option is using a shed but the one we have is unheated and reloading in 17-degree weather doesn't exactly entice me right now.

When I was in a similar situation, I bought a "The C4m3ron" reloading bench. It's not being made anymore, but it was a simple bench made out of wood that you would put a ~25lb bag of sand or shot on the inside to stabilize it.

I now use it for my CPS Primer, so I can prime in the living room.

However, there are some really badass solutions posted here. The closet and metal work cabinet are pretty amazing compact setups. That Harrel's compact press seems like a very elegant solution.

I now use it for my CPS Primer, so I can prime in the living room.

However, there are some really badass solutions posted here. The closet and metal work cabinet are pretty amazing compact setups. That Harrel's compact press seems like a very elegant solution.

This^^. I also run the C4m3ron with a Dillon 550 but you could make your own "H-box" type mini table and attach a press to it. It is a truly portable solution, but once you load it with a sandbag, it sucks to move. Unless you bench 275 and something about bow kills and concrete  I've used mine in the kitchen, spare bedroom and even in my camper.

I've used mine in the kitchen, spare bedroom and even in my camper.

Uh...regarding the vid selection.....there is an OFF button on that TV.....Bolts and wing nuts. Makes it easy to put on the coffee table and then remove when you’re done. Mines in the converted garage but if I move I’ll do the same thing in the living room.

View attachment 7564625

(Don’t say shit about what I have playing, I’ve seen everything else)

I have nothing to add, many great ideas already listed. I just wanted to give you my condolences for your loss.

There was a guy at the range that had a co/ax press on a pince is 2x10 about 2 1/2 foot long setting bullet length . Ask him how that was working out ? He told me that was how he sized ad seated all his ammo at home . Told wthat he had very little space in his apartment.

How do like the primer, that’s a weak link in my reloading process that I think is causing me problems shooting. Was is worth the price?When I was in a similar situation, I bought a "The C4m3ron" reloading bench. It's not being made anymore, but it was a simple bench made out of wood that you would put a ~25lb bag of sand or shot on the inside to stabilize it.

I now use it for my CPS Primer, so I can prime in the living room.

View attachment 7566538

However, there are some really badass solutions posted here. The closet and metal work cabinet are pretty amazing compact setups. That Harrel's compact press seems like a very elegant solution.

How do like the primer, that’s a weak link in my reloading process that I think is causing me problems shooting. Was is worth the price?

This primer seater is badass. After using it for the first time, I wanted to prime more brass. I've NEVER wanted to prime more brass at the end of a session before having this tool, before I couldn't wait to get done with priming.

I loaded up some rounds with different seating depths, to see if seating depth has an effect on SD/ES, I just haven't had a time to go to the range to try them out yet.

Is it worth it? I would say so, but I HATED priming before getting this tool, I was using a hand primer before this. It's really, really high quality. @orkan nailed it with this product. I actually enjoy priming now, which alone makes it worth the investment in my mind. Only you can make the decision of if a product is worth it to you or not, but it's definitely a high quality product that makes the reloading process easier, more comfortable and more precise. How much that is worth to you is something only you can decide.

I highly doubt you will regret getting one.

Similar threads

- Replies

- 17

- Views

- 783

- Replies

- 152

- Views

- 4K

- Replies

- 7

- Views

- 352