I hate rebarreling - especially if the gun is a shooter before.

I am the proud owner of a very rare lefty 40X in 308 (original barrel stamped "7.62 NATO"), it has been a shooter since I got it, but barrels are - for non-safe queen rifles - meant to be replaced.

The time came for the original to go and a new barrel. I chose a Rock barrel off a group buy a few months back. Rock's have always done right by me, why fix what ain't broken.

For the work, I took the gun to Roberts Precision outside Houston. Aaron is perfectionist in his work, and it definitely shows on the range.

I asked that he check the specs on the action, see if anything needed truing. It is a testament to Remington's efforts with the 40X series that nothing needed adjusting.

The new barrel was same contour and cut to 20 inches. The threading is almost a work of art, I almost hate to cover it with a can. Almost.

With a brand new barrel, I always start with factory ammo. That way, if I encounter a problem, it is either an ammo problem or a barrel problem, neither of which did I make. Ammo for today was 168-gr Hornady TAP, it isn't the most accurate, but is consistent.

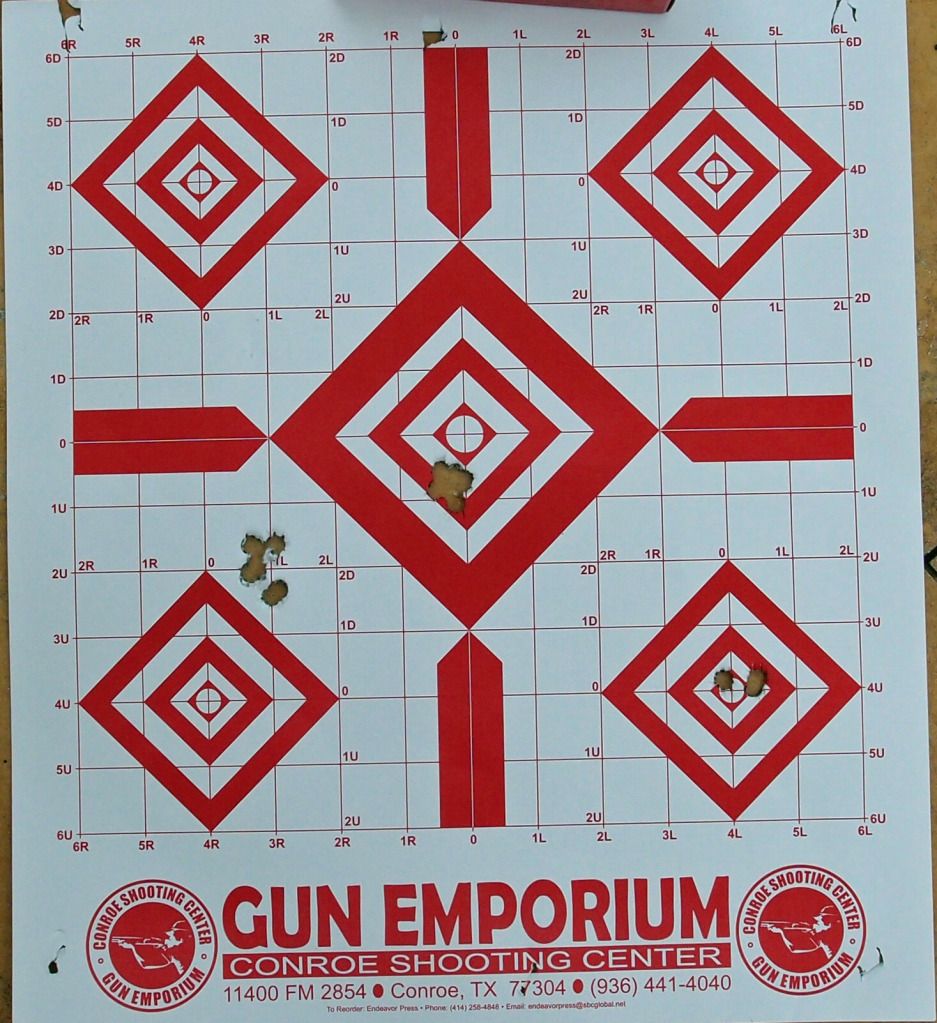

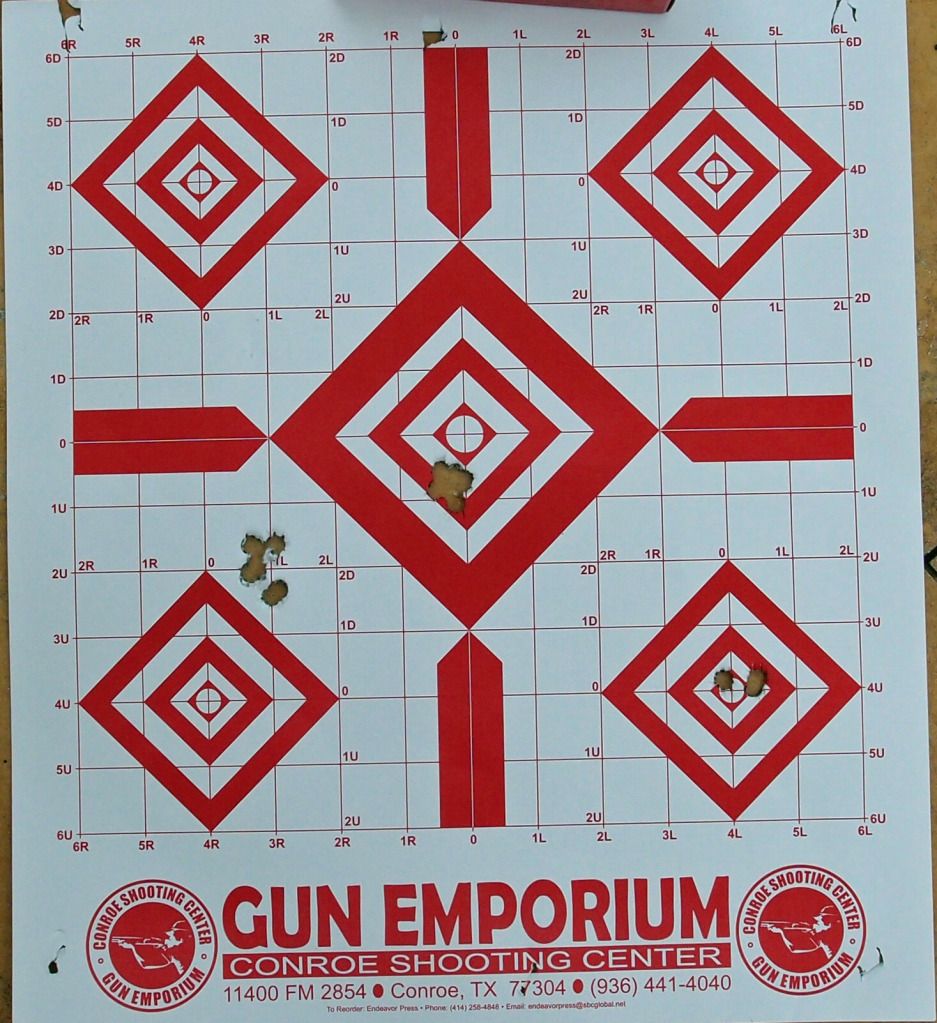

I show both targets and ammo expended as full disclosure, 20 rounds fired, 20 rounds accounted for. The target with one hole was the first round (cold, clean barrel, cold shooter) and was my first round down the new barrel.

From there, I loaded 10 rounds into the mag, and fired the lower left group on the bottom target. It was 10 shots measuring 0.818 MOA. For factory ammo, 10 rounds, I am pleased.

The middle group is 6 rounds, measuring 0.528 with an average center-to-center of .213.

All in all, exceptionally pleased with the workmanship and very happy with the barrel precision and accuracy.

Every 308 I've owned loved 44.5 grains of Varget over a 168 A-max seated 0.005 off the lands, we'll see how this barrel does with that recipe.

Anyone needing smith work done in the greater Houston area, Aaron does exceptional work.

I am the proud owner of a very rare lefty 40X in 308 (original barrel stamped "7.62 NATO"), it has been a shooter since I got it, but barrels are - for non-safe queen rifles - meant to be replaced.

The time came for the original to go and a new barrel. I chose a Rock barrel off a group buy a few months back. Rock's have always done right by me, why fix what ain't broken.

For the work, I took the gun to Roberts Precision outside Houston. Aaron is perfectionist in his work, and it definitely shows on the range.

I asked that he check the specs on the action, see if anything needed truing. It is a testament to Remington's efforts with the 40X series that nothing needed adjusting.

The new barrel was same contour and cut to 20 inches. The threading is almost a work of art, I almost hate to cover it with a can. Almost.

With a brand new barrel, I always start with factory ammo. That way, if I encounter a problem, it is either an ammo problem or a barrel problem, neither of which did I make. Ammo for today was 168-gr Hornady TAP, it isn't the most accurate, but is consistent.

I show both targets and ammo expended as full disclosure, 20 rounds fired, 20 rounds accounted for. The target with one hole was the first round (cold, clean barrel, cold shooter) and was my first round down the new barrel.

From there, I loaded 10 rounds into the mag, and fired the lower left group on the bottom target. It was 10 shots measuring 0.818 MOA. For factory ammo, 10 rounds, I am pleased.

The middle group is 6 rounds, measuring 0.528 with an average center-to-center of .213.

All in all, exceptionally pleased with the workmanship and very happy with the barrel precision and accuracy.

Every 308 I've owned loved 44.5 grains of Varget over a 168 A-max seated 0.005 off the lands, we'll see how this barrel does with that recipe.

Anyone needing smith work done in the greater Houston area, Aaron does exceptional work.