So I've wanted to test this for a while and finally got around to it. For compressed loads, the bullets can get marked/damaged pretty easily, and if seating stem doesn't fit bullet PERFECTLY, I suspected it would cause accuracy issues.

Today, I found my proof...

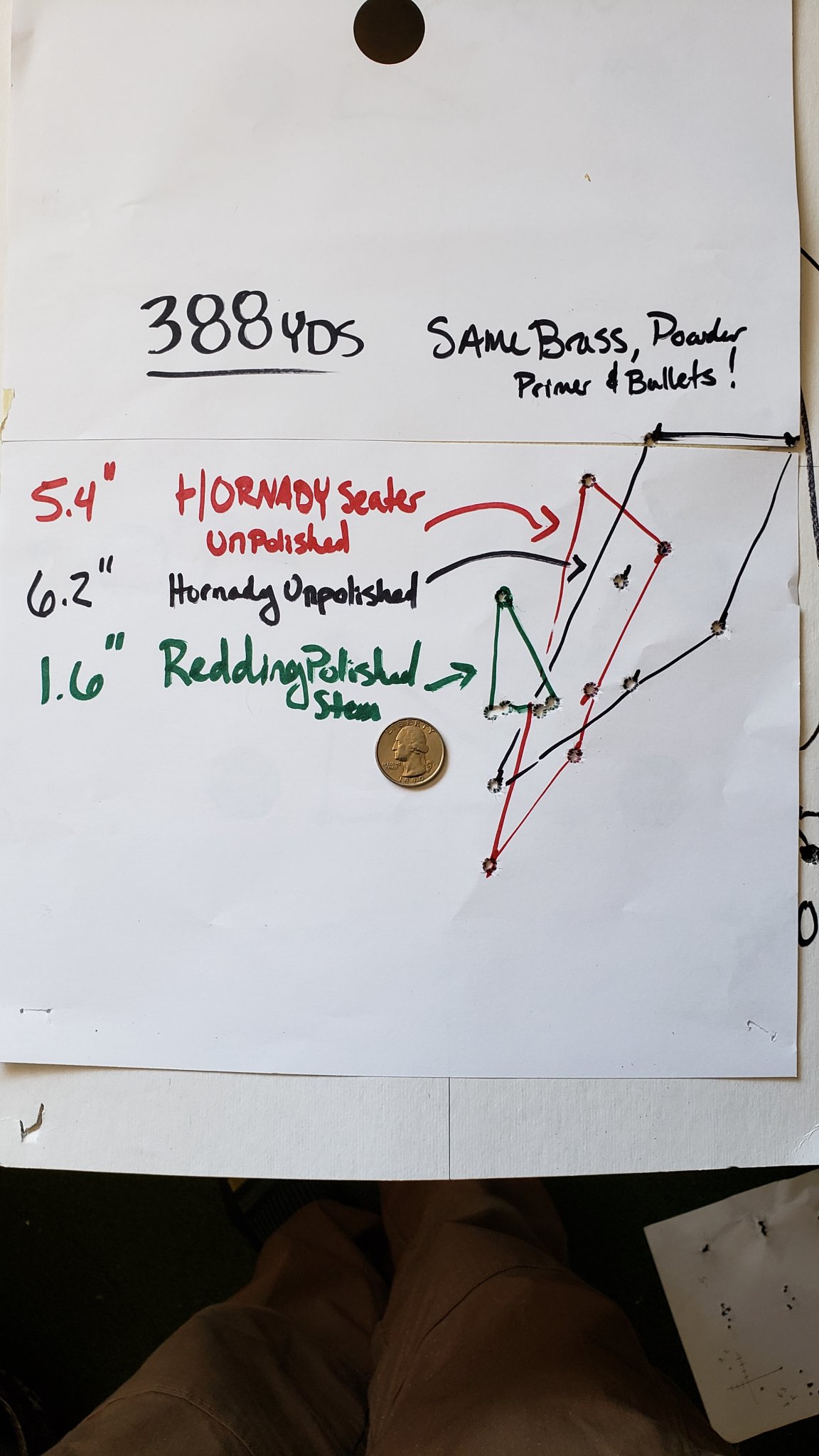

224 Valkyrie, Hornady 2nd fire brass, BR2 primers, 26.8gr H4350 seated to 2.302 OAL for all rounds. The only variables: two different seating stems/dies.

Die #1 Hornady Custom grade VLD seating stem (the bigger opening of the two stems provided in package). Unpolished, right out of the box.

Die #2 Redding seating stem ground by hand using bullet coated in valve grinding compound and finish lapped with #000 steelwool and JB2 borepaste. This has been my die for last several hundred rounds and it's been working well, but I just decided to buy a new set for giggles to test this.

5 rounds using Hornady stem (Red Sharpie)

5 rounds with Redding (Green Sharpie)

6 with Hornady stem but using pulled bullets (Black Sharpie, previously loaded, not fired and separated for use in a new load). All bullets marked with sharpie to ensure I could identify which shot was which on paper.

I shot the bullets randomly (loaded 6 rounds into mag in mixed sequence red, green, black.) Then the next 10 using same method (mixed order red, green, black). Fired rapidly (no more than 2-3 seconds between shots) and continuously between the two mags.

Shot at 388yds ; Target speaks for itself:

Color me stupified... I never thought I'd EVER see that kind of difference due to anular marks on the bullet from seating.

Conclusion: if you are shooting compressed loads or getting bad seating stem marks on loaded rounds, polish your stem until you get ZERO marks on bullets. Consistentcy should improve dramatically at distance.

Today, I found my proof...

224 Valkyrie, Hornady 2nd fire brass, BR2 primers, 26.8gr H4350 seated to 2.302 OAL for all rounds. The only variables: two different seating stems/dies.

Die #1 Hornady Custom grade VLD seating stem (the bigger opening of the two stems provided in package). Unpolished, right out of the box.

Die #2 Redding seating stem ground by hand using bullet coated in valve grinding compound and finish lapped with #000 steelwool and JB2 borepaste. This has been my die for last several hundred rounds and it's been working well, but I just decided to buy a new set for giggles to test this.

5 rounds using Hornady stem (Red Sharpie)

5 rounds with Redding (Green Sharpie)

6 with Hornady stem but using pulled bullets (Black Sharpie, previously loaded, not fired and separated for use in a new load). All bullets marked with sharpie to ensure I could identify which shot was which on paper.

I shot the bullets randomly (loaded 6 rounds into mag in mixed sequence red, green, black.) Then the next 10 using same method (mixed order red, green, black). Fired rapidly (no more than 2-3 seconds between shots) and continuously between the two mags.

Shot at 388yds ; Target speaks for itself:

Color me stupified... I never thought I'd EVER see that kind of difference due to anular marks on the bullet from seating.

Conclusion: if you are shooting compressed loads or getting bad seating stem marks on loaded rounds, polish your stem until you get ZERO marks on bullets. Consistentcy should improve dramatically at distance.