I’m not so sure.

From the little I understand about how rings clamp upon the scope tube, it’s a particularly springy sort of clamp dynamic where the tube itself is more active in the system than, say, clamping a stainless steel block.

Sort of like clamping jello vs clamping concrete.

If you look at slow motion vids of harder hitting rifles you’ll see the scope flexing around. Add a (relatively) heavy WMLRF or possibly a

hand pressing down and I could see some pressure imparted upon the scope tube.

Pretty close to worst-case:

Another (slightly less) worst-case (lead-sled type, read the description why it’s hard on scopes):

I include this vids as they vibrate the scope/ring/rail system enough

to be seen clearly. Not suggesting that your 21 lbs 6br or 22LR does a similar amount of vibe.

I mean, besides the MBrace design, most other scope rings use just the itty-bitty threads of 4 to 6 tiny screws to stand in-between a WMLRF that’s rocking a ring cap and the scope tube.

Although to be fair, Near Alphamount rings use 8 screws up front, and the Area419 rings have a dowel pin on each ring side that might limit back/forth rocking a bit.

Perhaps most scope tubes on an 6br are strong enough for hand pressure, especially if it’s not a gorilla doing it

. I guess we don’t hear of a rash of scope failures attributed to hand pressure on diving boards. Not sure anyone would draw that inference, however, leaving the issue hidden.

However, over time with a WMLRF or spotlight up there (like the night-hunter Euros tend to do) I’m not so sure. A bunch more mechanical advantage occurring. Especially with a harder kicking caliber.

And it sounds like WMLRF are now being used more often in certain comps.

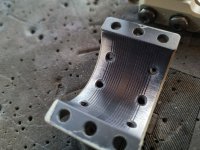

The MBrace one-piece pretty much just

eliminates that potential, uh, “joint” (for lack of a better non-engineer-guy term). At least that’s what its design appears (to me) to do.

I’ll let the engineers chime in with their much more informed opinions.

@E. Bryant @308pirate @koshkin

hawkinsprecision.com