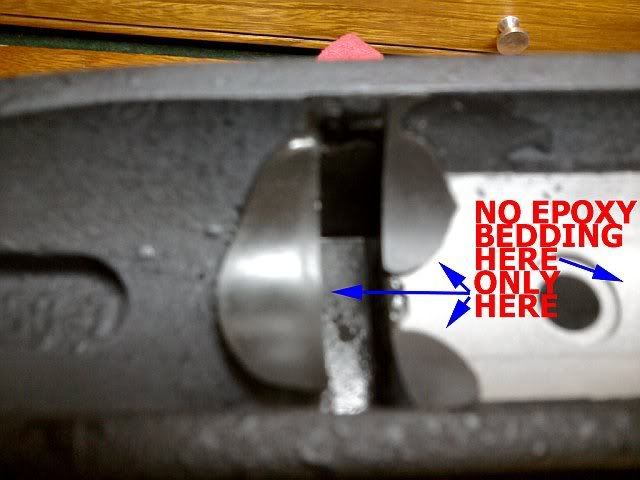

I have a GAP Remington 700 .308 with a 22" flutted barrel that I recently sent in to have fit to my Bell & Carlson Tactical Medalist stock. When I received the rifle back, I had to remove the stock and sent it in to Badger to inlet the Badger trigger guard/magazine system. When I removed the barrel, I noticed that the only "fitting" that the other shop did to the stock was apply some epoxy at the barrel lug (rather than remove material from the stock so the barrel could lay down in it). The result is that the stock is now sitting up about 1/8" above the front pillar (there is a gap between the pillar and the action), and the barrel make some contact with the stock for about 4"-5" from the barrel lug outward, then it is free floating.

So I am planning on removing the stupid epoxy and inletting the stock for the barrel (the action is inletted fine). My question is: Should the barrel be free floated ormake descent contact with the stock uniformly?

I have all the proper tools for the barrel inletting, and am planning on going VERY slowly. Any input, tips are GREATLY appreciated.

Thanks,

Ken

So I am planning on removing the stupid epoxy and inletting the stock for the barrel (the action is inletted fine). My question is: Should the barrel be free floated ormake descent contact with the stock uniformly?

I have all the proper tools for the barrel inletting, and am planning on going VERY slowly. Any input, tips are GREATLY appreciated.

Thanks,

Ken