Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

The Shot You’ll Never Forget Giveaway - Enter To Win A Barrel From Rifle Barrel Blanks!

Tell us about the best or most memorable shot you’ve ever taken. Contest ends June 13th and remember: subscribe for a better chance of winning!

Join contest Subscribe

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sidearms & Scatterguns Red Dot Dilemma

- Thread starter NFAJohn

- Start date

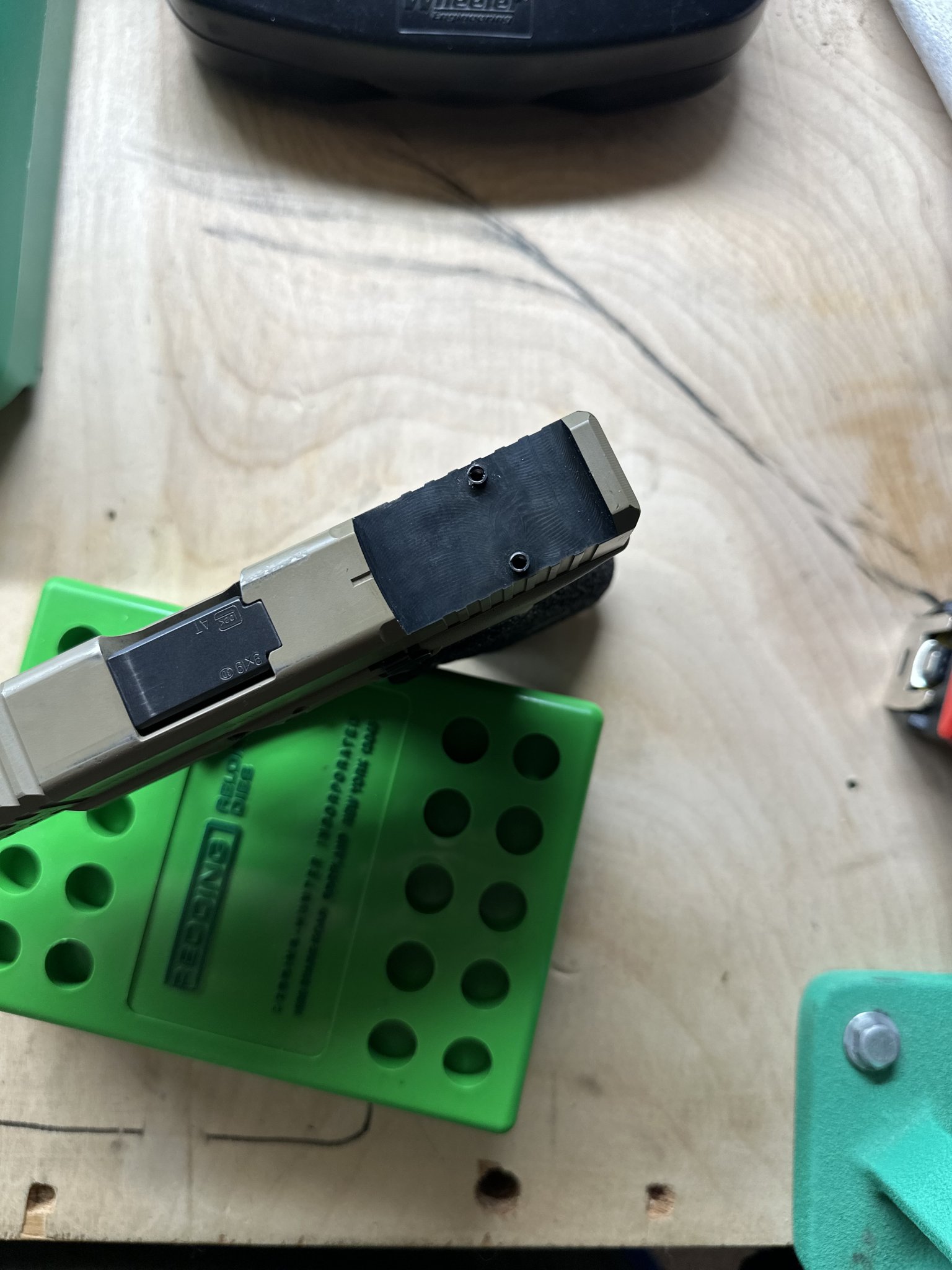

Where are the bosses that are supposed to fit in the two round recesses at the bottom front of the RMR?LOL! Wins the internet for the day.

View attachment 8414839

I will say the milling / machining looks pretty rough. It may not really matter functionally. But I'm not impressed with the workmanship.

View attachment 8414840

The RMR HD does not need a sealing plate. It's closed underneath just like the SRO. The battery is replaced from above again like the SRO.I can’t tell if you are running a Trijicon sealing plate, or is sealing up the battery compartment not necessary for this application? Curious minds and stuff…

Ha! I just added that same question to my previous comment.Where are the bosses that are supposed to fit in the two round recesses at the bottom front of the RMR?

Trijicon put those holes under the optics for a reason. The people who think they're not needed because the optic is "captured" by the ends of the cut have no fucking idea what they're talking about.Ha! I just added that same question to my previous comment.

First they seem to forget that you have to have some clearance between the optic and the cut or the optic won't go in.

Second they have no idea if putting longitudinal stresses on the body of the optic is going to damage the circuitry inside because they have no idea how the optic is actually made. C-More specifically prohibits having contact between the ends of the optic cut and the ends of the optic's housing. Its installation instructions actually call out a minimum gap.

Just because some get away with it without damage to the optic doesn't mean it's right.

Not to mention it then puts all the lateral stresses on the screws.Trijicon put those holes under the optics for a reason. The people who think they're not needed because the optic is "captured" by the ends of the cut have no fucking idea what they're talking about.

First they seem to forget that you have to have some clearance between the optic and the cut or the optic won't go in.

Second they have no idea if putting longitudinal stresses on the body of the optic is going to damage the circuitry inside because they have no idea how the optic is actually made. C-More specifically prohibits having contact between the ends of the optic cut and the ends of the optic's housing. Its installation instructions actually call out a minimum gap.

Just because some get away with it without damage to the optic doesn't mean it's right.

The RMR HD does not need a sealing plate. It's closed underneath just like the SRO. The battery is replaced from above again like the SRO.

Well, there’s my dipshit post of the day. Glad it’s out of the way.

Ya so I didn't realize that the bosses were missing, were gonna see how it holds up I suppose. The shop did make a big deal about using their screws and only their screws when mounting the optic. I was told by the owner that they are some high grade, but in retrospect it damn sure seems like a cost saving measure to not machine in the bosses.

I work in oil and gas and the saying goes there are three options

1 Fast

2 Cheap

3 Good

Problem is you can only ever get two at the same time, it would appear I got 1&2 unfortunately.

I'm going to mount it and see how it goes, I will say the optic fit in there SNUG. I mean it took a little push with the thumbs to seat it, maybe between that and the rough machining it will extra hold onto it lol. I'll be sending another pistola up to LRI for a cut next week just in case because after messing with this for just a bit last night dot is the way.

I work in oil and gas and the saying goes there are three options

1 Fast

2 Cheap

3 Good

Problem is you can only ever get two at the same time, it would appear I got 1&2 unfortunately.

I'm going to mount it and see how it goes, I will say the optic fit in there SNUG. I mean it took a little push with the thumbs to seat it, maybe between that and the rough machining it will extra hold onto it lol. I'll be sending another pistola up to LRI for a cut next week just in case because after messing with this for just a bit last night dot is the way.

Last edited:

Hey man be the guy who's optic cut is missing bosses and is still somewhat happy about it lolWell, there’s my dipshit post of the day. Glad it’s out of the way.

Best you can do with what you've got.Ya so I didn't realize that the bosses were missing, were gonna see how it holds up I suppose. The shop did make a big deal about using their screws and only their screws when mounting the optic. I was told by the owner that they are some high grade, but in retrospect it damn sure seems like a cost saving measure to not machine in the bosses.

I work in oil and gas and the saying goes there are three options

1 Fast

2 Cheap

3 Good

Problem is you can only ever get two at the same time, it would appear I got 1&2 unfortunately.

I'm going to mount it and see how it goes, I will say the optic fit in there SNUG. I mean it took a little push with the thumbs to seat it, maybe between that and the rough machining it will extra hold onto it lol. I'll be sending another pistola up to LRI for a cut next week just in case because after messing with this for just a bit last night dot is the way.

If you ever need replacement screws, McMaster Carr has stuff that is made to ASME/ANSI and/or mil std.

Stars might line up just right and this will work out or I'll have a nifty paperweightBest you can do with what you've got.

If you ever need replacement screws, McMaster Carr has stuff that is made to ASME/ANSI and/or mil std.

I’ve never had the optics off my guns to check the machine work, optics were sent and were mounted at mod1 so I can’t tell if it’s a new thing to save money or not. I can rip an optic off later if you’d like.

Two pistols both with over 7k on each, classes, single hand malfunction clearing, mammoth sniper challenge etc etc without issue. I never even would have thought about the optic cut / quality until you posted to be honest. I think you should be ok.

0 affiliation with mod1 just giving you my experience

Two pistols both with over 7k on each, classes, single hand malfunction clearing, mammoth sniper challenge etc etc without issue. I never even would have thought about the optic cut / quality until you posted to be honest. I think you should be ok.

0 affiliation with mod1 just giving you my experience

I've got a tube of JB Weld and the battery top loads, it's gonna work out one way or another.I’ve never had the optics off my guns to check the machine work, optics were sent and were mounted at mod1 so I can’t tell if it’s a new thing to save money or not. I can rip an optic off later if you’d like.

Two pistols both with over 7k on each, classes, single hand malfunction clearing, mammoth sniper challenge etc etc without issue. I never even would have thought about the optic cut / quality until you posted to be honest. I think you should be ok.

0 affiliation with mod1 just giving you my experience

Maybe I'll start a bed you red dot optics trend and laugh at the poors who don't bed rmrs.

Guys @j-moose32 is solid people. He reached out to Mod1 to be like hey wtf I recommended yall and this looks sketch, splain yourself.

There are bosses just at the location of the screws, it looks like this with screws removed. Per the owner that’s just how they do them and in their experience with the stronger screws it’s not an issue.

I’m gonna wring it out and I’ll keep everyone updated. Again big thank you to everyone for all the input.

There are bosses just at the location of the screws, it looks like this with screws removed. Per the owner that’s just how they do them and in their experience with the stronger screws it’s not an issue.

I’m gonna wring it out and I’ll keep everyone updated. Again big thank you to everyone for all the input.

Not to mention it then puts all the lateral stresses on the screws.

Exactly, screws are meant to take tensile stress not shear stress.

Guys @j-moose32 is solid people. He reached out to Mod1 to be like hey wtf I recommended yall and this looks sketch, splain yourself.

There are bosses just at the location of the screws, it looks like this with screws removed. Per the owner that’s just how they do them and in their experience with the stronger screws it’s not an issue. View attachment 8415015

I’m gonna wring it out and I’ll keep everyone updated. Again big thank you to everyone for all the input.

It's better than no bosses but still not as good as the original Trijicon design.

The approach your shop took forces you to use #4 screws instead of the #6 screws specified by Trijicon. #4 screws can only take about 50 - 60% of the torque that a #6 can.

Most gun modifiers aren't engineers and do shit by trial and error hoping the design safety margins will make up for the guesswork.

We’re talking what 10-12 inch pounds of torque? I know the lateral shearing is different but for torque values on the screw I would this both are welllll under SMYSIt's better than no bosses but still not as good as the original Trijicon design.

The approach your shop took forces you to use #4 screws instead of the #6 screws specified by Trijicon. #4 screws can only take about 50 - 60% of the torque that a #6 can.

Most gun modifiers aren't engineers and do shit by trial and error hoping the design safety margins will make up for the guesswork.

Last edited:

10 to 12 for #4. 18 to 20 for #6. All these values are for steel on steel thread engagement. I don't remember how much to lower them for steel on aluminum.We’re talking what 10-12 inch pounds of torque? I know the lateral shearing is different but for torque values on the screw I would this both are welllll under SMYS

Started at 15 leaning on my range bag

5, 2, 3. Felt pretty dialed in so 1, felt like any error there was most likely me induced so shot a 15 round mag of my carry ammo (Winchester 147+p) at 4. Seemed pretty locked on minus the one low one from me getting cocky and being stupid.

Top two targets were back to range ball trying to come from low ready to one round each. Left to right just trying to track the dot.

I made an absolute God awful mess of the center trying to really press the firing pace I won’t show yall

Overall no complainants other than I need more time with it. We’ll see over time how it hold zero. Auto brightness worked well.

Just a further update. Mod1 said this way “gives more thread engagement , and centers the pivot point for return to zero.”

Not arguing for or against this, just providing info. I don’t know enough from an engineering aspect to know what way is better.

My personal experience with the cuts though- I’ve got two pistols with SROs cut by MOD1 - one with 7k and one with 8500ish. Both have had 0 issues.

Fairly confident you’ll have no issues @NFAJohn but keep us all posted for sure. Bigger brains than me are saying there is a better way for doing cuts so I’ll keep it in mind for my next one too

Not arguing for or against this, just providing info. I don’t know enough from an engineering aspect to know what way is better.

My personal experience with the cuts though- I’ve got two pistols with SROs cut by MOD1 - one with 7k and one with 8500ish. Both have had 0 issues.

Fairly confident you’ll have no issues @NFAJohn but keep us all posted for sure. Bigger brains than me are saying there is a better way for doing cuts so I’ll keep it in mind for my next one too

That may or may not matter. It all depends on how deep the cut is made on the slide and how much thickness remains under the cut.Just a further update. Mod1 said this way “gives more thread engagement ,

LOL......see that's bullshit. I'd ask to see a diagram proving this. Simple trigonometry is all they need.and centers the pivot point for return to zero.”

I made an absolute God awful mess of the center trying to really press the firing pace I won’t show yall.

I think you should show it. We might be able to give some ideas on how to improve that.

Oh bro that target is in the circular filling system. I stepped on the gas probably has hard as I could, don’t get me wrong it was in the guy, but it looked like a dense pattern of #4 buckI think you should show it. We might be able to give some ideas on how to improve that.

I tried to keep it simple, G17 and G43x. I was hoping to keep the grip angle the same (stupid).

I sent both slides off to Wager Machine Works. With cutting and cerakote it was $120 each and turn around from the day it shipped out to back in my hands was around a week.

I went with the 6 MOA RMR and the 2 MOA EPS carry. The RMR dot is much nicer and is probably more durable but the Holosun came with an adapter plate, 3 sets of screws and it even has buttons that don't feel like pushing on a rotten potato.

I sent both slides off to Wager Machine Works. With cutting and cerakote it was $120 each and turn around from the day it shipped out to back in my hands was around a week.

I went with the 6 MOA RMR and the 2 MOA EPS carry. The RMR dot is much nicer and is probably more durable but the Holosun came with an adapter plate, 3 sets of screws and it even has buttons that don't feel like pushing on a rotten potato.

I think that Trijicon engineers are the only ones that ever looked at the size of their fingertips before designing the controls on their RDS.I tried to keep it simple, G17 and G43x. I was hoping to keep the grip angle the same (stupid).

I sent both slides off to Wager Machine Works. With cutting and cerakote it was $120 each and turn around from the day it shipped out to back in my hands was around a week. View attachment 8415688

I went with the 6 MOA RMR and the 2 MOA EPS carry. The RMR dot is much nicer and is probably more durable but the Holosun came with an adapter plate, 3 sets of screws and it even has buttons that don't feel like pushing on a rotten potato.

I almost need a stick or a pencil to use the buttons on the other brands I've owned (C-More and Holosun).

I don't have small, soft and supple hands by any means. But I still think I prefer the Holosun buttons. I guess time will tell. Over the last month I haven't had any issues with them being depressed accidentally but I can say I don't enjoy the RMR buttons. It doesn't really change much on a range gun though.

The RMR looks way cooler, so there's that.

The RMR looks way cooler, so there's that.

LOLWUT? What does that even mean?I can say I don't enjoy the RMR buttons.

Anyway I run my carry gun optics (all RMRs) in auto brightness and don't ever turn them off.

It means they are stiff and squishy without any adjustment feedback other than looking down the sight. They work but I don't like them.LOLWUT? What does that even mean?

Anyway I run my carry gun optics (all RMRs) in auto brightness and don't ever turn them off.

The holosun is easily adjusted through my shirt.

Tactile buttons bring joy... simple.

Just a further update. Mod1 said this way “gives more thread engagement , and centers the pivot point for return to zero.”

Not arguing for or against this, just providing info. I don’t know enough from an engineering aspect to know what way is better.

My personal experience with the cuts though- I’ve got two pistols with SROs cut by MOD1 - one with 7k and one with 8500ish. Both have had 0 issues.

Fairly confident you’ll have no issues @NFAJohn but keep us all posted for sure. Bigger brains than me are saying there is a better way for doing cuts so I’ll keep it in mind for my next one too

I have 2 SROs and one RMR done by Mod1. No issues on my end either.

Trijicon put those holes under the optics for a reason. The people who think they're not needed because the optic is "captured" by the ends of the cut have no fucking idea what they're talking about.

First they seem to forget that you have to have some clearance between the optic and the cut or the optic won't go in.

Second they have no idea if putting longitudinal stresses on the body of the optic is going to damage the circuitry inside because they have no idea how the optic is actually made. C-More specifically prohibits having contact between the ends of the optic cut and the ends of the optic's housing. Its installation instructions actually call out a minimum gap.

Just because some get away with it without damage to the optic doesn't mean it's right.

You're a relative newcomer to this but want to teach everyone else what you know, same as every other subject.

First, Trijicon initially put those holes for bosses in the RMR because it was designed to mount on the ACOG, not a milled pistol slide. The holes weren't put there for locating the RMR in pistol slides, because the RMR wasn't designed for pistol slides; it was just tough enough that it worked. Trijicon did not come up with the idea of the slide mounted RMR; that was strictly a custom job by small shops for years before there were aftermarket slides made for them, and major manufacturers incorporating red dots.

Thousands of RMRs were installed in slides without bosses before you ever took notice - it worked great when the slide cut was fit well. The tolerances of the RMR body are very tight - enough that a slide cut for a snug fit with one works with most RMRs. You don't need constraints both in the cut and the bosses; tolerance stackup leads to only using some of those constraints but not all of them, as any decent engineer should understand.

The advantage to using bosses in the slide is for mass production - the cut can be a little looser for easy installation and to fit any optic, and most optics other than the RMR have much larger tolerances so they need it. With the DPP mentioned earlier, bosses are absolutely necessary because the tolerances of that optic body are pretty large; IIRC Leupold recommends about .015" clearance while an RMR cut can be fit to .000"-.001".

Nothing wrong with slides machined to use bosses, but a custom snug fit slide for the RMR can and does work without bosses, as has been proven for years. That is specific to the RMR optic, and there is more than one way to skin that cat.

You keep talking about tolerances as if you actually had access to these people's engineering drawings. We all know that you don't, and that's the only place you will find dimensional tolerances.No. Just stop with the know-it-all bs.

You're a relative newcomer to this but want to teach everyone else what you know, same as every other subject.

First, Trijicon initially put those holes for bosses in the RMR because it was designed to mount on the ACOG, not a milled pistol slide. The holes weren't put there for locating the RMR in pistol slides, because the RMR wasn't designed for pistol slides; it was just tough enough that it worked. Trijicon did not come up with the idea of the slide mounted RMR; that was strictly a custom job by small shops for years before there were aftermarket slides made for them, and major manufacturers incorporating red dots.

Thousands of RMRs were installed in slides without bosses before you ever took notice - it worked great when the slide cut was fit well. The tolerances of the RMR body are very tight - enough that a slide cut for a snug fit with one works with most RMRs. You don't need constraints both in the cut and the bosses; tolerance stackup leads to only using some of those constraints but not all of them, as any decent engineer should understand.

The advantage to using bosses in the slide is for mass production - the cut can be a little looser for easy installation and to fit any optic, and most optics other than the RMR have much larger tolerances so they need it. With the DPP mentioned earlier, bosses are absolutely necessary because the tolerances of that optic body are pretty large; IIRC Leupold recommends about .015" clearance while an RMR cut can be fit to .000"-.001".

Nothing wrong with slides machined to use bosses, but a custom snug fit slide for the RMR can and does work without bosses, as has been proven for years. That is specific to the RMR optic, and there is more than one way to skin that cat.

PS nobody cares how long you've been doing anything.

You keep talking about tolerances as if you actually had access to these people's engineering drawings. We all know that you don't, and that's the only place you will find dimensional tolerances.

PS nobody cares how long you've been doing anything.

Typical response from you - you don't have the experience to talk about the facts presented, so you attack my credibility instead. Anyone caring to read back can see that pattern in this thread and every other one where someone doesn't support your claims.

The RMR tolerances I mentioned are from experience with a bunch of them; they are as consistent as I've said and my findings matched that of other people milling slides before pistol optics started becoming mainstream. In fact, if you knew as much about this as you'd like everyone to think, I'll bet you'd have brought up an argument about the Type 2 RMR being ~.003" longer than the older versions. They're consistent enough that you can tell if one of them is an original or Type 2 by measuring the base length. That's a point in favor of using bosses for mass produced slides and semi-custom jobs so they'll fit any RMR, but it also speaks to how consistent they are and suited well for a custom job with a snug fit. FWIW the Holosuns with the RMR base pattern are pretty consistent too; not at the same level as the RMR but more than adequate for good fit in RMR milled slides, with or without bosses.

That's called practical experience - it doesn't come from a manufacturer's drawing, or any theories about what should or shouldn't work.

Oh yeah - what about "lateral loads" mentioned earlier? Pistol slides move front to back. Sure, you can apply lateral loads with an impact in hard use, but a good milling job without bosses is more than up to the task; you can practically drive nails with them. Between the curvature of the front of the RMR cutout and the screws themselves, lateral loads are not an issue.

Also, some people use RMR as a generic name for any pistol red dot, but I don't. My comments about RMRs are specifically about the actual RMRs made by Trijicon.

Regarding Leupold tolerances, I did get slide cutout drawings for DPP milling directly from Leupold through a contact there, and that drawing had the specification for ~.015" (IIRC) clearance front and rear of the base. At that time at least, they were providing that drawing for people with a need for it; maybe they still do and you could always ask them for a copy. These use a separate base plate that doesn't consistently match up with the body, and you can't get away with a snug fit milling job unless it's only intended to fit one specific optic. I've only milled a few slides for these (3 to be exact) but don't really like them and don't feel they're suited well for carry.

Sometimes experience actually matters to get the facts right; contrary to your personal brand, theory doesn't trump reality, and bluster and insults are a poor substitute for understanding how things actually work and fit together. Am I the only one to recognize that while you to claim I'm showing off rather than just sharing correct info, you've always been the one trying to prove something? Frankly, your posts here are classic narcissism - pretending that your theory of why something won't work is somehow more relevant than the fact that it does and has worked for years. Same for the question of co-witnessed iron sights, and a lot of other topics; you don't have facts or solid reasoning to back up your claims but fall back on insults and snide comments. What makes you feel so much more knowledgeable than anyone else here? Get help instead of being such a smug know-it-all, especially if you're not going to bother learning the facts.

That's called practical experience - it doesn't come from a manufacturer's drawing, or any theories about what should or shouldn't work.

Tolerances aren't determined by drawings, but rather tooling, right?

(I am neither an engineer nor a machinist.)

Tolerances aren't determined by drawings, but rather tooling, right?

(I am neither an engineer nor a machinist.)

Yes, in practical terms that’s correct. The drawings will specify what maximum tolerances the manufacturer allows, but the tooling may create parts to a tighter tolerance than the drawing.

In the case of Trijicon’s RMR sights, 308pirate is right that I don’t know what Trijicon specifies for tolerances on their drawings, but I do have a pretty good idea of the variation in the end result from experience. Granted, a sample size of roughly 30 RMRs is pretty small relative to the size of Trijicon’s production, and we could get into statistics and all that nerd stuff, but in practical terms for the ordinary guy, if you have a slide milled for a close fit with one RMR (especially the newer Type 2) chances are very high it’ll fit another RMR without being too tight or too loose.

Besides all that, the same considerations apply to the dimensions and tolerances of the locating holes in the RMR too. If the argument is that we don’t know what the tolerances for the optic base are, then how would we know them for the bosses either?

For the person who's gonna bring the dumpster fire back from the dead in 2027 here is the link to the running review.

www.snipershide.com

www.snipershide.com

Sidearms & Scatterguns - RMRHD Running Review

I recently picked up a RMRHD after some input from others here https://www.snipershide.com/shooting/threads/red-dot-dilemma.7215163/ and thought I'd do a running review of the optic. Couple of disclaimers, I'm a regular dude who A didn't receive this thing for free (be cool if I did tho) and B...

The tooling, the machine itself, the fixturing, the skill of the operator, and even the quality of the material being cut can affect the tolerances.Tolerances aren't determined by drawings, but rather tooling, right?

(I am neither an engineer nor a machinist.)

For example, 4140 from two different steel companies can make a difference in not only finish, but dimensions.

I run lathes in a tool and die shop, and just got done with a small run of inserts for a mold. The pieces I started with were a mixture of 4140 from at least two different suppliers. Some would come out nice and shiny and right on size, others would come out about .001" under and look dull.

Giving this a push @NFAJohn, have you had an opportunity for more range,carry time? Considering the information presented in this thread, feeling somewhat willing to follow you down this path but with the ARCOP2 on my G4/19.

Probably going to use Jagerworks for milling, no irons with mounting is far backwards as possible.

Probably going to use Jagerworks for milling, no irons with mounting is far backwards as possible.

Tolerances aren't determined by drawings, but rather tooling, right?

Tolerances are stated on engineering drawings. Period.

What you and almost everyone else thinks of as tolerances is actually dimensional variation. That's determined by the process used to create a particular feature and tooling is only one of the many factors that controls that variation.

Question from a novice: Would it be a reasonable statement to say Tolerances are a spec and goal, while Dimensional Variation is a result?Tolerances are stated on engineering drawings. Period.

What you and almost everyone else thinks of as tolerances is actually dimensional variation. That's determined by the process used to create a particular feature and tooling is only one of the many factors that controls that variation.

Hey brother follow link, I started another thread to do a running review on the RMRHD.Giving this a push @NFAJohn, have you had an opportunity for more range,carry time? Considering the information presented in this thread, feeling somewhat willing to follow you down this path but with the ARCOP2 on my G4/19.

Probably going to use Jagerworks for milling, no irons with mounting is far backwards as possible.

I won’t be going back to irons and I love not having a read iron to clutter up the sight picture. I’m heading to the pasture here in a bit to run another 250 through it and I’ll update this evening.

The RMRHD is badass, the forward facing light sensor in stupid fast. X300 won’t wash it out and as soon as the light is cut it’s dim again. I feel like a goober for waiting this long to take the plunge.

As far as carrying it, I’ve been toting it around in a comptac IWB holster and have zero complaints.

Sidearms & Scatterguns - RMRHD Running Review

I recently picked up a RMRHD after some input from others here https://www.snipershide.com/shooting/threads/red-dot-dilemma.7215163/ and thought I'd do a running review of the optic. Couple of disclaimers, I'm a regular dude who A didn't receive this thing for free (be cool if I did tho) and B...

there are a few holsters out there for the 6 second mount stillThis has been my setup for the past 10 years, I had a ALG holster that vanished with a bunch of other stuff moving across states. Tried my best to dremel up a JMCustom kydex but ended up making a mess out of things. Basically this has been a range/nightstand gun since that time. Will get the slide sent out this week.

View attachment 8426719

i still use a mk1 off the grid holster but they have the adr 6 second holster now that has more optons

there are a few other's also for the 6 second mount

CorrectQuestion from a novice: Would it be a reasonable statement to say Tolerances are a spec and goal, while Dimensional Variation is a result?

Actually the goal, from a process control standpoint, is to be as close to nominal as possible.

^^^^What he said. You may have +- .005" on your print, but the goal is to not use it.

Looks good, I think your going to like deleting the rear irons. I've been shooting the crap out of mine and don't see going back to a rear iron.

On my Glock 43x I personally run the EPS carry dot. Haven’t touched the battery in 8-10 months

I've got one on a S&W M&P 5.7 that's been going strong for over a year, I'll probably end up doing 1.5y battery cycles instead of 1On my Glock 43x I personally run the EPS carry dot. Haven’t touched the battery in 8-10 months

Question made it to the range today with ARCO, after about 75 rounds it loosened up, would a little locktite do the trick?

I did hand tighten it down and ran another 75 rounds without issue. Still waiting on JMCustom for holster

not a complaint Tony is still within his online posted time frame. Brought my G17 along for a side by side comparison

the T-1 still has a sharper red dot image when compared with ARCO P2.

image when compared with ARCO P2.

I did hand tighten it down and ran another 75 rounds without issue. Still waiting on JMCustom for holster

not a complaint Tony is still within his online posted time frame. Brought my G17 along for a side by side comparison

the T-1 still has a sharper red dot

Last edited:

Similar threads

Sidearms & Scatterguns

Red dot on Glock without slide cut?

- Replies

- 30

- Views

- 869

- Replies

- 5

- Views

- 299

- Replies

- 2

- Views

- 318