This is why most of the top industry experts and/or shooters rarely if ever post here.

You assholes come out with your pitchforks and 1970’s fudd opinions.

Literally just showed you a video of one of the best in the world, who makes a living doing T&E for most every major company out there. And you still say it’s wrong.

Dude, don't get so goddamn emotional, I'm not attacking you.

You found ONE guy that promotes this. That's not good enough when every quality mfg. like Dewey or Tipton make rods with free spinning handles and don't make ANY drill related cleaning products. There's probably a reason, because Dewey will make anything.

We have plenty of experts on here, industry and otherwise as well as some known shooters and you know that. It's an insult to them to indicate otherwise.

And you could argue I used to be one of 'em. I ran in their circles. I've talked to a lot of mfg.'s and was on first name basis with many. Because we ran the first SDM school, we had to have a cleaning method. We adopted the one most NM shooters were using since we based the school on NM fundamentals to begin with. I still use the same method because it works very well and it can't damage my weapons even if I tried.

Again, seen a pressure washer with boiling water make a SAW white glove ready. It was CLEAN. But WRONG. It didn't fuck the gun up that day, or even the day after. But over time it would have. I've seen a lot of fucked up shit from improper cleaning methods that some Fudd swore by, almost ALWAYS a shortcut of some kind...

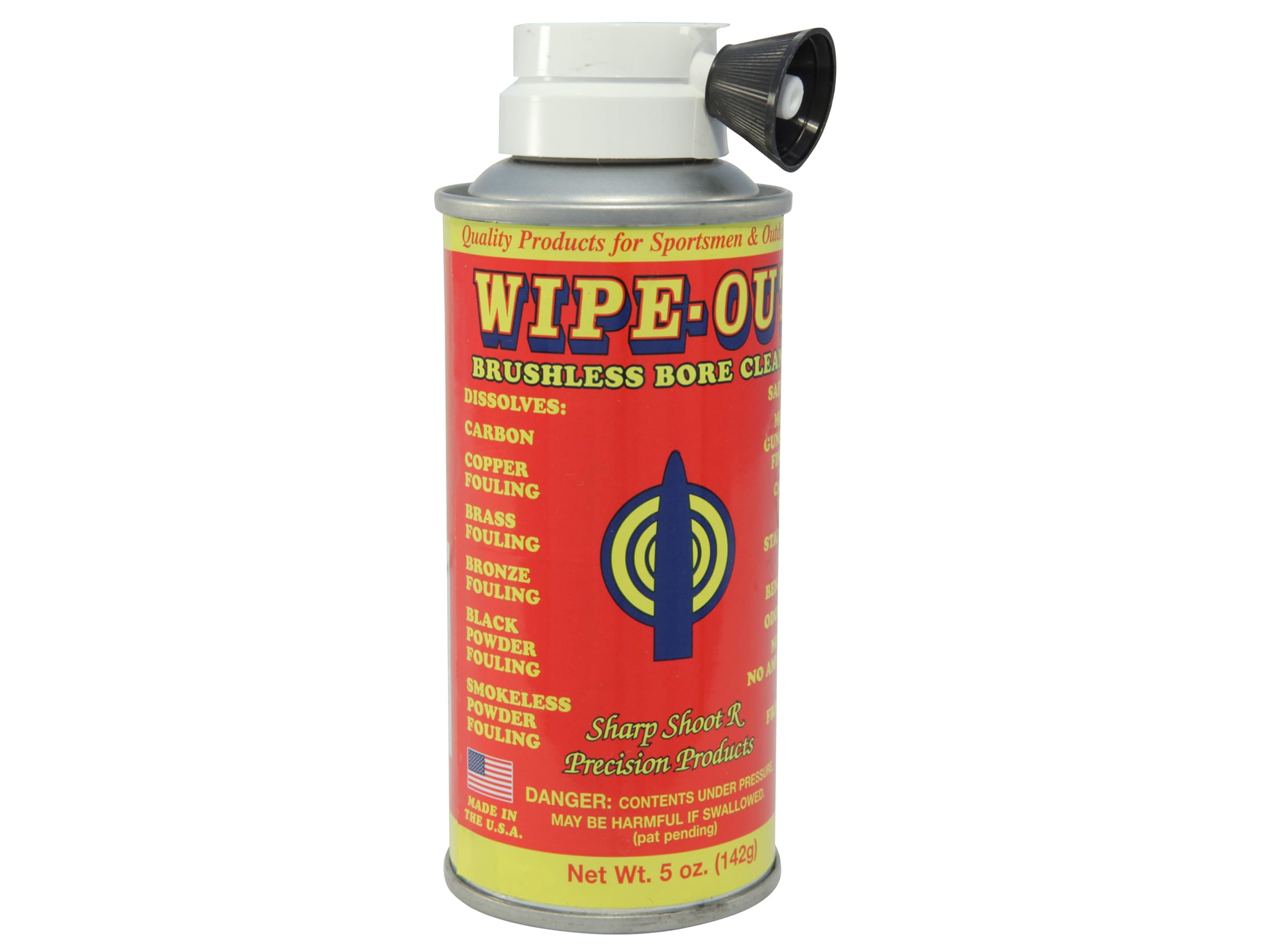

I tried it... in 15 minute increments... as the bottle says not use it longer than that.

It didn't work as well as Butch's... Sitting for a day.... or two....

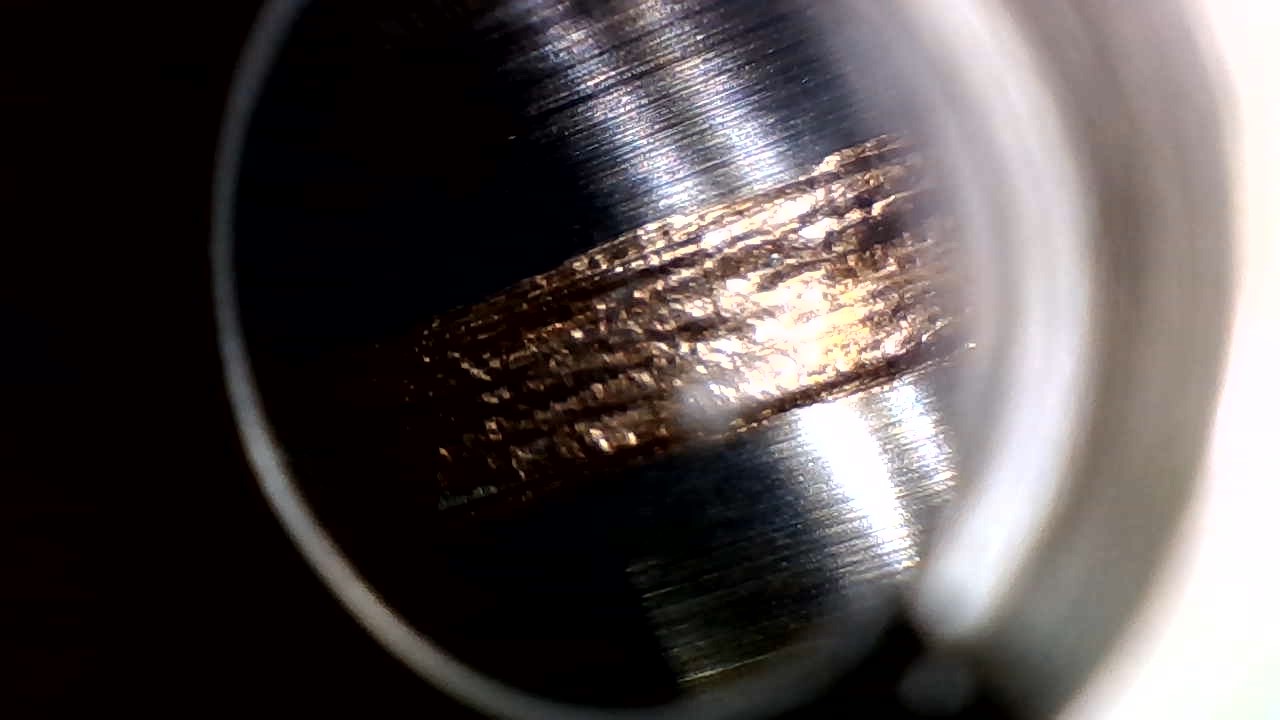

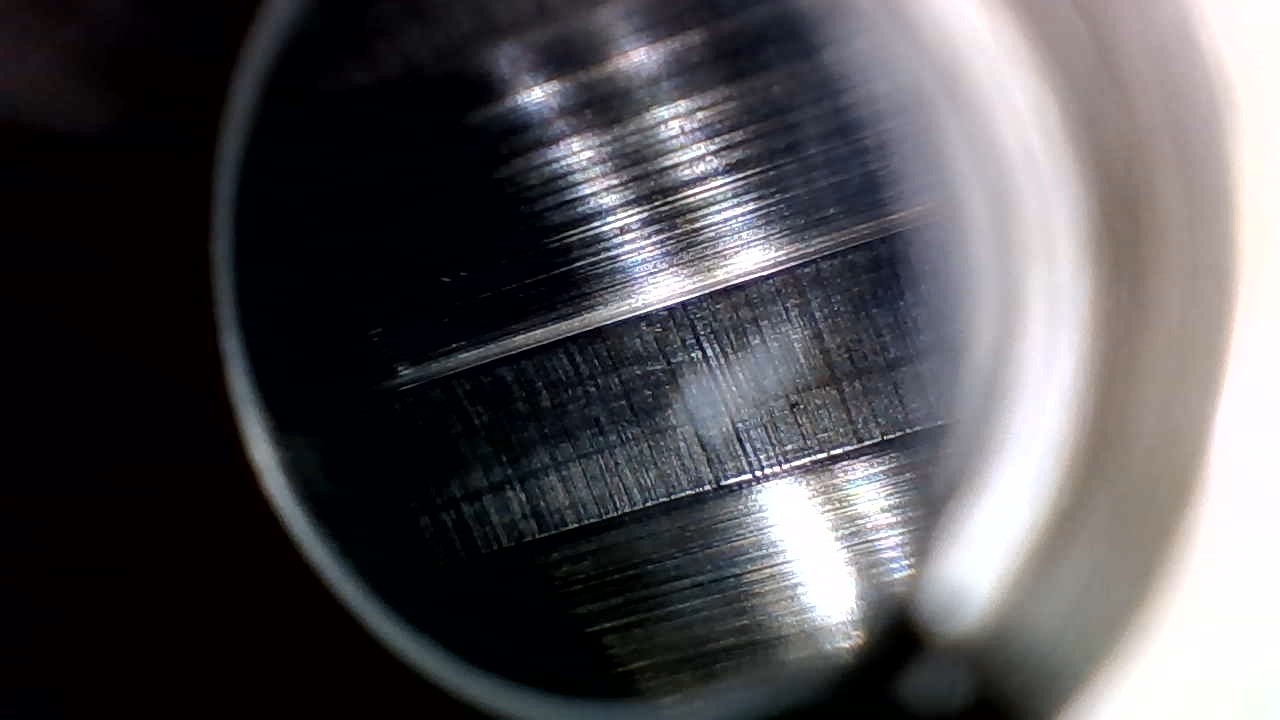

LIke I said, clean barrel first. Then swab liberally with the Sweets, soak it. Run brushes behind it, just wipe 'em off well because Sweets will eat copper or bronze brushes. Clean out and repeat.

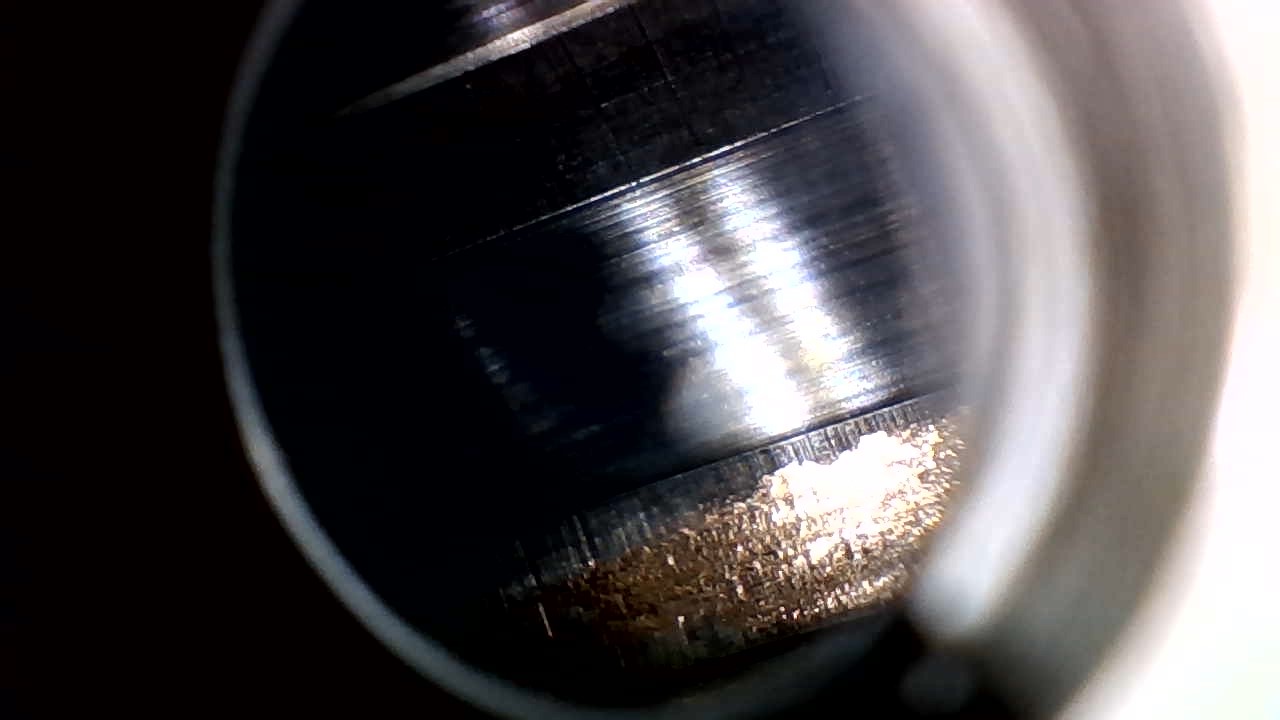

You don't want the Sweets sitting for too long in one place or it starts to do it's own damage but people have left it in there for much, much longer. Just be smart and safe about it. With as much copper as you have in that barrel, it may take a while for chemistry and brushes to erode that down enough to do away with it. Perhaps trying that freezer/boiling water method is a good idea, I don't know, I do know that'll fuck up some materials.

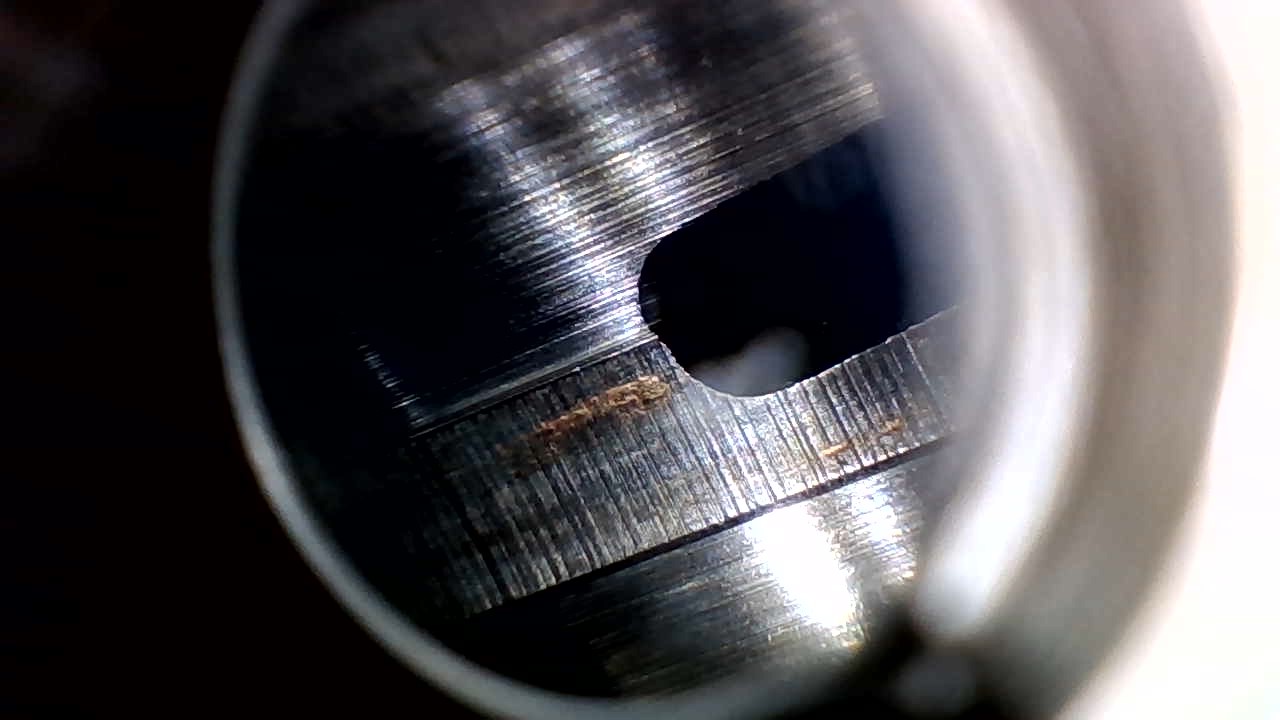

Be patient. I don't think I've ever seen fouling so bad before and I'm talking about 240's and SAWs and shit here.