Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

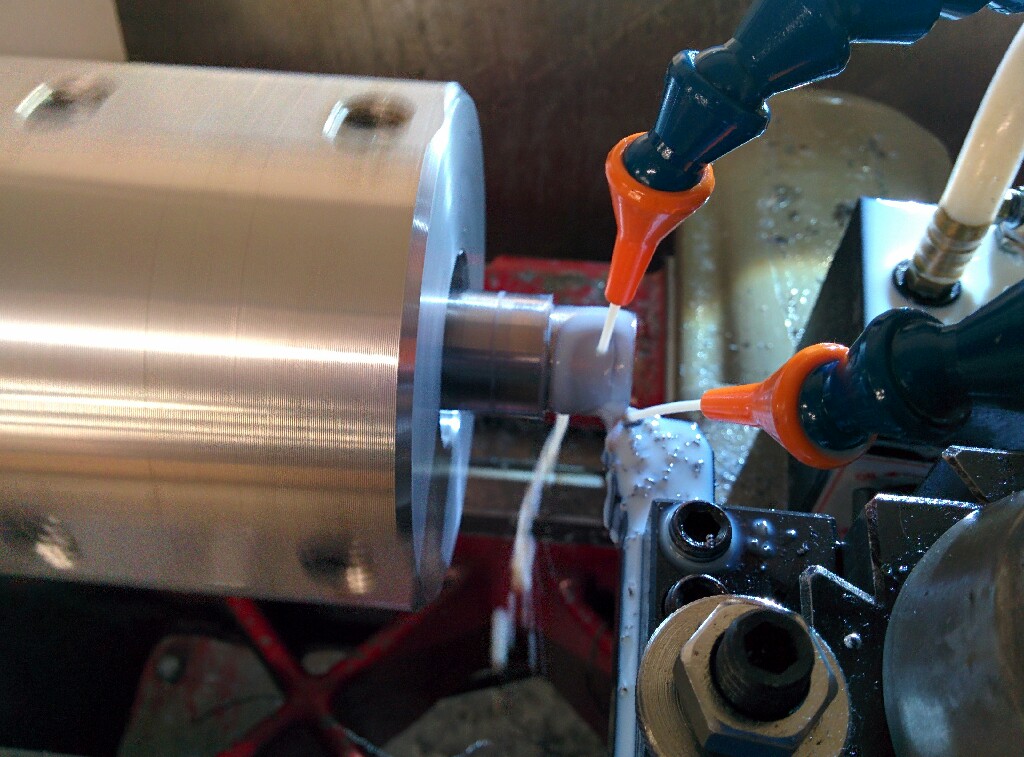

Gunsmithing Robert Gradous chambering on his HAAS TL-1

- Thread starter Bob L Swagger

- Start date

I don't post much because of my spelling. Cutting oil high sulfer, active, nonactive sulfer, fat, clornated, long chain parifanted fats.

If only the AMU (DOD) hadn't had a hiring freeze a few years ago, I quiet possibly would be doing this right now. I would love to learn how to gun smith. Have a guy in Pine Mountain Ga. that told me to stop by anytime to learn, may have to take him up on it. He's got CNC machines and all, just wished I could afford my own. Nice Video...

I don't post much because of my spelling.

Post away, the rest of us southerners don't know no better anyhow.

Post away, the rest of us southerners don't know no better anyhow.

Neither do us "Yanks!"

I don't post much because of my spelling. Cutting oil high sulfer, active, nonactive sulfer, fat, clornated, long chain parifanted fats.

Don't worry about the spelling, but can you answer me in simple terms? Any brand names, viscosity, etc? Like Moly-Dee and Vactra2 mixed with some chicken bones.....?

Yea, they like to talk about how "we talk" and spell. "Behind your back or on-line!"

I don't post much because of my spelling. Cutting oil high sulfer, active, nonactive sulfer, fat, clornated, long chain parifanted fats.

I don't post much because of my spelling. Cutting oil high sulfer, active, nonactive sulfer, fat, clornated, long chain parifanted fats.

Robert keep turning out the lasers you build don't worry about spelling, don't you know none of us southern boys can spell!

Got you another fan here in Rome, he is buying up parts right now and will be in touch to get in line... Maybe I'll be able to see that HAAS in action soon.

Nice video Swagger..

Don't worry about the spelling, but can you answer me in simple terms? Any brand names, viscosity, etc? Like Moly-Dee and Vactra2 mixed with some chicken bones.....?

Mobil-met 766 is pretty popular with a few top level guys I know around here. Moly-D and 766 can both be had from McMaster for about 1/2 the price of what Grizzly charges for them.

I have an unopened 5 gallon pail of 766 sitting on my floor, I've been using a 50W-90 high sulfur gear oil from Walmart for quite a while now, the stuff cuts better than any "dark, sulfur, chlorinated thread cutting oil" that I've ever used. And even better, it goes for about $17/gal on sale.

Bob,

Very cool video.

What is Roberts first choice in reamers these days?

Thanks,

Paul

I really need to hurry up and buy that bolt knob from you. Can you Cerakote it if I can't get it in time for my Smith.

Bob,

Very cool video.

What is Roberts first choice in reamers these days?

Thanks,

Paul

Do you have C 30118 Federal Standard Field Drab, Sir? I like the 4G Knob, with my Stiller Tac 30.

Bob,

Very cool video.

What is Roberts first choice in reamers these days?

Thanks,

Paul

Do you have C 30118 Federal Standard Field Drab, Sir? I like the 4G Knob, with my Stiller Tac 30.

Bullydog,

Sorry, but I only stock FDE,Sniper Grey, and Graphite Black.

Paul

Mobil-met 766 is pretty popular with a few top level guys I know around here. Moly-D and 766 can both be had from McMaster for about 1/2 the price of what Grizzly charges for them.

I have an unopened 5 gallon pail of 766 sitting on my floor, I've been using a 50W-90 high sulfur gear oil from Walmart for quite a while now, the stuff cuts better than any "dark, sulfur, chlorinated thread cutting oil" that I've ever used. And even better, it goes for about $17/gal on sale.

Exactly what oil is this you found at wal-mart? Brand ? name ?

Map1Tech 80W-90 Gear Lubricant.

AKA, the cheapest 1gal jug of gear oil that Walmart had on the shelf in the automotive section a couple years ago.

I checked, it's 80W-90, not the 50W I reported above. It's almost syrup-y and it stinks terribly, but man does it cut well.

AKA, the cheapest 1gal jug of gear oil that Walmart had on the shelf in the automotive section a couple years ago.

I checked, it's 80W-90, not the 50W I reported above. It's almost syrup-y and it stinks terribly, but man does it cut well.

Map1Tech 80W-90 Gear Lubricant.

AKA, the cheapest 1gal jug of gear oil that Walmart had on the shelf in the automotive section a couple years ago.

I checked, it's 80W-90, not the 50W I reported above. It's almost syrup-y and it stinks terribly, but man does it cut well.

Thanks for the tip, ill give it a try

The squealing of the reamer made me nervous but you guys obviously know what you are doing. What am I missing?

The squealing of the reamer made me nervous but you guys obviously know what you are doing. What am I missing?

The "singing" isn't an issue. Chatter is which sounds very differently.

The principle difference here is he's NOT pussy footing the tool or the spindle. When you first address the rigidity issue (which he's done) you can confidently start running feeds/speeds that are more aligned to every day machining. If I were drilling/reaming a hole in a cnc mill I'd be running rates straight off the chart from the manufacturer as a start point. No reason you cant with form tools either (which is what a chamber reamer really is) SO long as you have your setup right.

RG has it figured out. Pretty cool to see someone else pushing it this way. What he's doing is essentially EXACTLY what we gravitated towards over a year ago. The new reamer format I stumbled onto last year is what allows all of this. A solid carbide tool with a reduced flute count and a staggered chip breaker setup as a finisher instead of the conventional rougher. Notice the lack of floating reamer holder? It's a rigid ER32 collet setup. Again, something I've been using now for almost 5 years. If the tool is straight, no reason to float anything other than they tramp oil in a coolant tank.

Only difference I see is a slight reduction in speeds and feeds, probably because the Haas isn't quite as massive/rigid as our lathe (my turret alone weighs a 1000+lbs) and its an open architecture machine where's ours is fully enclosed. (easier to manage the mess that coolant/cutting fluid makes under high pressure) Probably also because cutting fluid would be head to toe if he cranked it up.

We've gotten away from oil completely and switched to water based synthetics. The advantages for us are enormous. No smoke, no oils atomized to inhale. No mess, easier to sterilize parts for cerakote, doesn't swell the seals in the machines, etc. NO STINK FOOT ODOR!

I made 400 claw clamps for our 2.4ULTACH hardware out of 6AL4V TI with a single HSS 1/4-28 tap and one HIGH SPEED STEEL drill. I still use the tap for random stuff I'm doing as well. Didn't even rub the coating!

Times are a changin!

Last edited:

Only difference I see is the difference in speeds and feeds, probably because the Haas isn't quite as massive/rigid as our lathe. (my turret alone weighs a 1000+lbs) That and we've gotten away from oil completely and switched to water based synthetic. The advantages for us are enormous. No smoke, no oils atomized to inhale. No mess, easier to sterilize parts for cerakote, doesn't swell the seals in the machines, etc. NO STINK FOOT ODOR!

Chad, curious water water based synthetic you're using?? My lathe is in my garage and I'm concerned about cutting fluid odor so I'd be interested in hearing about a less potent smelling option. Going to be using a through the barrel flushing system if it matters.

Jason

The "singing" isn't an issue. Chatter is which sounds very differently.

The principle difference here is he's NOT pussy footing the tool or the spindle. When you first address the rigidity issue (which he's done) you can confidently start running feeds/speeds that are more aligned to every day machining. If I were drilling/reaming a hole in a cnc mill I'd be running rates straight off the chart from the manufacturer as a start point. No reason you cant with form tools either (which is what a chamber reamer really is) SO long as you have your setup right.

RG has it figured out. Pretty cool to see someone else pushing it this way. What he's doing is essentially EXACTLY what were doing. The new reamer format we switched to over a year ago is what this is. A solid carbide tool with a reduced flute count and a staggered chip breaker. Notice the lack of floating reamer holder? It's a rigid ER32 collet setup. Again, something I've been using now for almost 5 years.

Only difference I see is a slight reduction in speeds and feeds, probably because the Haas isn't quite as massive/rigid as our lathe (my turret alone weighs a 1000+lbs) and its an open architecture machine where's ours is fully enclosed. (easier to manage the mess that coolant/cutting fluid makes under high pressure)

We've gotten away from oil completely and switched to water based synthetics. The advantages for us are enormous. No smoke, no oils atomized to inhale. No mess, easier to sterilize parts for cerakote, doesn't swell the seals in the machines, etc. NO STINK FOOT ODOR!

I made 400 claw clamps for our 2.4ULTACH hardware out of 6AL4V TI with a single HSS 1/4-28 tap and one HIGH SPEED STEEL drill. I still use the tap for random stuff I'm doing as well. Didn't even rub the coating!

Times are a changin!

Thanks for the explanation. As usual, I learned something new here.

Maybe I will have one of you guys chamber my next barrel. I get the results I want with my manual setup but it just takes soooo much time and angst.

Who reams and head spaces barrels with screwed-on extensions? Please PM for a rough idea on pricing, turn-around time, and how you prefer the components (extension installed or not, barrel profiled or not, etc.)

Last edited:

Blaser Vasco 7000

Do you feel that is a good choice in a turning center even with standard HSS reamers? From their site, it sounds like it will be a very good all around coolant for all the materials I will be working with.

Last edited:

Bert,

It's been the shit for us. I'm using it in all of our equipment now. Even the band saw!

Soup it up to 10% for chambering. Get a fish pump that'll make bubbles in your coolant tank. Then get a skimmer.

It'll keep your shop from smelling like swamp thing.

It's been the shit for us. I'm using it in all of our equipment now. Even the band saw!

Soup it up to 10% for chambering. Get a fish pump that'll make bubbles in your coolant tank. Then get a skimmer.

It'll keep your shop from smelling like swamp thing.

Where are you guys buying Vasco 7000? I googled it just to find the cost for 5 gallons and don't get anything but a corporate website and some press releases. Guess I need to call around locally.

J

J

Thats funny you mentioned about the fish tank air pump, i have been in the process of putting together a kit to sell locally to my customers that turns on the pump when the main breaker of the machine is off so at night bacteria doesn't form and the coolant stays aerated. Chad sorry I havent gotten back with you regarding your Doosan work shift issue been busy fixing up a supermax. Ill give you a buzz towards the end of this week.

Bert,

It's been the shit for us. I'm using it in all of our equipment now. Even the band saw!

Soup it up to 10% for chambering. Get a fish pump that'll make bubbles in your coolant tank. Then get a skimmer.

It'll keep your shop from smelling like swamp thing.

You'll need to find an industrial tooling house that's a Blaser rep.

It's about $35/gallon and the smallest quantity available is a 5 gallon pail.

Now, here's the deal on this stuff. First, it's awesome, but if your switching over from oil you have a long, long weekend ahead of you.

1. Your machine has to be absolutely sterile from any cutting oil. Otherwise your just pissing $ down the drain. I mean, pumps, sumps, lines, way surfaces, etc. Get all that sulpherized chit out of there first. I mean, assholes and elbows clean. Get out the scub pads, old shitty clothes, crank up the music and have the pizza/beer guy on speed dial.

2. Then you get 5 gallons or so of coolant system sterilizer and you run a recommended mix through your ENTIRE SYSTEM for about a day. Every couple hours you skim the tramp oil in the sump with a shop vac, top it off, spike your water with more sterilizer, and continue. This gets all the old funk out of the system. I used CimClean from CimCool.

3. Next, you rinse with clean water for another couple hours. Twice is even better.

Three of us spent almost two days doing this on our lathe. Trips to the car wash with the coolant sump on a trailer, etc. It's a WHOLE LOT OF WORK and it MUST be done if you want a predictable outcome.

Now you mix your coolant. There's a science to this.

1. Full 5 gallon pail of clean water.

2. Pitcher of pure coolant (it'll resemble cooking oil)

3. You'll need a drill and a paint mixer

4. Extra pair of hands.

ONE nearly full pitcher to 5 gallons of water gives you an approximate 10% concentration.

You ADD COOLANT TO HIGHLY AGITATED WATER ONLY

Do not deviate from this one bit or all bets are off. There's some chemistry shit going on here that needs to take place. I don't profess to know why nor do I care, but the Blaser rep made this very, very clear to me when we switched over. Your mix will resemble a glass of milk being rinsed out in the sink. It'll have a clean/pleasant odor.

Add your coolant to your sump 1 5 gallon pail at a time. Check your percentage with a hydrometer. Don't guess. It's worth the $50 bucks to buy one.

When your coolant level gets low, mix up another 5 gallon pail and add. DO NOT just add coolant to your sump.

10% is what we use in the lathe. It's a little fat, but it's shown to work well for chambering. I use 8% in the mills.

Make damn sure your stuff is absolutely clean before you do this. NO SULPHERIZED CUTTING OIL or old funk. Otherwise your just pissing money down the drain. Use the fish pump and get a skimmer if you have a big sump (cnc shit) If your doing this with a

manual, use the shop vac once you detect tramp oil pooling on the surface. Keep the fish pump on 24/7.

You have to oxygenate the sump to mitigate the "bad" bacteria growth. Failure to do so is going to result in a shop that smells like a foot.

Last, if you live in an area where snow flies or shit freezes, buy your winter supply BEFORE the fall. If the stuff freezes while in transit, it's junk. This means garages that don't stay climate controlled in the winter are prolly better off sticking with oil.

Have fun, good luck. This stuff is the shit far as I'm concerned.

C.

It's about $35/gallon and the smallest quantity available is a 5 gallon pail.

Now, here's the deal on this stuff. First, it's awesome, but if your switching over from oil you have a long, long weekend ahead of you.

1. Your machine has to be absolutely sterile from any cutting oil. Otherwise your just pissing $ down the drain. I mean, pumps, sumps, lines, way surfaces, etc. Get all that sulpherized chit out of there first. I mean, assholes and elbows clean. Get out the scub pads, old shitty clothes, crank up the music and have the pizza/beer guy on speed dial.

2. Then you get 5 gallons or so of coolant system sterilizer and you run a recommended mix through your ENTIRE SYSTEM for about a day. Every couple hours you skim the tramp oil in the sump with a shop vac, top it off, spike your water with more sterilizer, and continue. This gets all the old funk out of the system. I used CimClean from CimCool.

3. Next, you rinse with clean water for another couple hours. Twice is even better.

Three of us spent almost two days doing this on our lathe. Trips to the car wash with the coolant sump on a trailer, etc. It's a WHOLE LOT OF WORK and it MUST be done if you want a predictable outcome.

Now you mix your coolant. There's a science to this.

1. Full 5 gallon pail of clean water.

2. Pitcher of pure coolant (it'll resemble cooking oil)

3. You'll need a drill and a paint mixer

4. Extra pair of hands.

ONE nearly full pitcher to 5 gallons of water gives you an approximate 10% concentration.

You ADD COOLANT TO HIGHLY AGITATED WATER ONLY

Do not deviate from this one bit or all bets are off. There's some chemistry shit going on here that needs to take place. I don't profess to know why nor do I care, but the Blaser rep made this very, very clear to me when we switched over. Your mix will resemble a glass of milk being rinsed out in the sink. It'll have a clean/pleasant odor.

Add your coolant to your sump 1 5 gallon pail at a time. Check your percentage with a hydrometer. Don't guess. It's worth the $50 bucks to buy one.

When your coolant level gets low, mix up another 5 gallon pail and add. DO NOT just add coolant to your sump.

10% is what we use in the lathe. It's a little fat, but it's shown to work well for chambering. I use 8% in the mills.

Make damn sure your stuff is absolutely clean before you do this. NO SULPHERIZED CUTTING OIL or old funk. Otherwise your just pissing money down the drain. Use the fish pump and get a skimmer if you have a big sump (cnc shit) If your doing this with a

manual, use the shop vac once you detect tramp oil pooling on the surface. Keep the fish pump on 24/7.

You have to oxygenate the sump to mitigate the "bad" bacteria growth. Failure to do so is going to result in a shop that smells like a foot.

Last, if you live in an area where snow flies or shit freezes, buy your winter supply BEFORE the fall. If the stuff freezes while in transit, it's junk. This means garages that don't stay climate controlled in the winter are prolly better off sticking with oil.

Have fun, good luck. This stuff is the shit far as I'm concerned.

C.

Last edited:

Blaser Vasco 7000

I've been using Houghton Hocut 795 because a friend gave me a pail of it.

I don't post much because of my spelling. Cutting oil high sulfer, active, nonactive sulfer, fat, clornated, long chain parifanted fats.

I know it's been said, but thanks again for all the advice you guys give. It's a huge help for those like me who have always wanted to build our own.

Personally, on a manual gunsmithing lathe, especially in a hobby capacity, I'd probably stick with a dark, high sulfur cutting oil like the Rigid dark thread cutting oil. But honestly, I had bad luck with the last Rigid dark. I was not getting the surface finish I once was. I switched to the Oatey brand and got my chamber surface back. Maybe I'm weird, but I like the smell of the Oatey brand....

My machine tech cringed when I told him I was probably going to run a dark, high sulfur oil in my turning center. He didn't have any mechanical issues with it but said it sucks for the guy working on it.

My machine tech cringed when I told him I was probably going to run a dark, high sulfur oil in my turning center. He didn't have any mechanical issues with it but said it sucks for the guy working on it.

You'll need to find an industrial tooling house that's a Blaser rep.

It's about $35/gallon and the smallest quantity available is a 5 gallon pail.

Now, here's the deal on this stuff. First, it's awesome, but if your switching over from oil you have a long, long weekend ahead of you.

1. Your machine has to be absolutely sterile from any cutting oil. Otherwise your just pissing $ down the drain. I mean, pumps, sumps, lines, way surfaces, etc. Get all that sulpherized chit out of there first. I mean, assholes and elbows clean. Get out the scub pads, old shitty clothes, crank up the music and have the pizza/beer guy on speed dial.

2. Then you get 5 gallons or so of coolant system sterilizer and you run a recommended mix through your ENTIRE SYSTEM for about a day. Every couple hours you skim the tramp oil in the sump with a shop vac, top it off, spike your water with more sterilizer, and continue. This gets all the old funk out of the system. I used CimClean from CimCool.

3. Next, you rinse with clean water for another couple hours. Twice is even better.

Three of us spent almost two days doing this on our lathe. Trips to the car wash with the coolant sump on a trailer, etc. It's a WHOLE LOT OF WORK and it MUST be done if you want a predictable outcome.

Now you mix your coolant. There's a science to this.

1. Full 5 gallon pail of clean water.

2. Pitcher of pure coolant (it'll resemble cooking oil)

3. You'll need a drill and a paint mixer

4. Extra pair of hands.

ONE nearly full pitcher to 5 gallons of water gives you an approximate 10% concentration.

You ADD COOLANT TO HIGHLY AGITATED WATER ONLY

Do not deviate from this one bit or all bets are off. There's some chemistry shit going on here that needs to take place. I don't profess to know why nor do I care, but the Blaser rep made this very, very clear to me when we switched over. Your mix will resemble a glass of milk being rinsed out in the sink. It'll have a clean/pleasant odor.

Add your coolant to your sump 1 5 gallon pail at a time. Check your percentage with a hydrometer. Don't guess. It's worth the $50 bucks to buy one.

When your coolant level gets low, mix up another 5 gallon pail and add. DO NOT just add coolant to your sump.

10% is what we use in the lathe. It's a little fat, but it's shown to work well for chambering. I use 8% in the mills.

Make damn sure your stuff is absolutely clean before you do this. NO SULPHERIZED CUTTING OIL or old funk. Otherwise your just pissing money down the drain. Use the fish pump and get a skimmer if you have a big sump (cnc shit) If your doing this with a

manual, use the shop vac once you detect tramp oil pooling on the surface. Keep the fish pump on 24/7.

You have to oxygenate the sump to mitigate the "bad" bacteria growth. Failure to do so is going to result in a shop that smells like a foot.

Last, if you live in an area where snow flies or shit freezes, buy your winter supply BEFORE the fall. If the stuff freezes while in transit, it's junk. This means garages that don't stay climate controlled in the winter are prolly better off sticking with oil.

Have fun, good luck. This stuff is the shit far as I'm concerned.

C.

I am by means a gunsmith, but I do shoot A LOT. I have to say the gunsmithing forum and Chad's posts in particular are incredibly enjoyable and educational reading. I love this stuff, maybe someday I'll get a little shop of my own to tinker in, but until then keep up the good work gentlemen and I'll keep reading!!!

-VB

Wow Chad, that seems like a lot of trouble. Is the Vasco 7000 that temperamental? Is this just standard practice for a machining center?

I run coolant when applicable and Viper's Venom when I need it (threading and chambering) and never worry about them mixing (just skim off the tramp oil occasionally). Aeration? Never bothered with that either. I've never gotten any foulness from the coolant (I think the Houghton coolant guarantees biostability as long as it is between 4 and 6%).

As far as mixing, I just turn on my pump and let it flow through the chip pan back to the sump for several minutes and check the Brix right from the nozzle. If it's low, I just dump more coolant into the sump; high and I just dump water into the sump, then check the Brix again in a few minutes.

Keep in mind that this is being used on an old SB13 and not a fancy machining center and my procedures are just what I picked up from my friends at an industrial machine shop. I'm certainly not a professional and all my work is done mostly as a hobby. I'd really like to know if I'm being derelict in my duties to my machines. I still clean and lube the machine with the Vactra oils every day as per the South Bend charts.

I run coolant when applicable and Viper's Venom when I need it (threading and chambering) and never worry about them mixing (just skim off the tramp oil occasionally). Aeration? Never bothered with that either. I've never gotten any foulness from the coolant (I think the Houghton coolant guarantees biostability as long as it is between 4 and 6%).

As far as mixing, I just turn on my pump and let it flow through the chip pan back to the sump for several minutes and check the Brix right from the nozzle. If it's low, I just dump more coolant into the sump; high and I just dump water into the sump, then check the Brix again in a few minutes.

Keep in mind that this is being used on an old SB13 and not a fancy machining center and my procedures are just what I picked up from my friends at an industrial machine shop. I'm certainly not a professional and all my work is done mostly as a hobby. I'd really like to know if I'm being derelict in my duties to my machines. I still clean and lube the machine with the Vactra oils every day as per the South Bend charts.

Hmmm...reading Chad's "some chemistry going on" comment, I'd wager there is a chemical emulsification that is occurring, and needs the water dispersion while mixing to enable that. With oil being verbotten, I'd imagine that the cutting oil would just cause the solution to clump up and end up clogging the system and allowing bacterial growth to occur.

Just a guess though...

Just a guess though...

Hmmm...reading Chad's "some chemistry going on" comment, I'd wager there is a chemical emulsification that is occurring, and needs the water dispersion while mixing to enable that. With oil being verbotten, I'd imagine that the cutting oil would just cause the solution to clump up and end up clogging the system and allowing bacterial growth to occur.

Just a guess though...

Pretty much spot on.

Understand that this is no more work than what any other coolant manufacturer would recommend if you were switching from a petroleum based cutting oil to a water based synthetic. Water/oil no mixy so it's just a matter of getting stuff prepped to ensure a predictable result.

Hmmm...reading Chad's "some chemistry going on" comment, I'd wager there is a chemical emulsification that is occurring, and needs the water dispersion while mixing to enable that. With oil being verbotten, I'd imagine that the cutting oil would just cause the solution to clump up and end up clogging the system and allowing bacterial growth to occur.

Just a guess though...

I've not experienced any of that, that's why I asked. I don't know if the Hocut is fundamentally different from the Vasco, so I just wonder if anyone has had problems with other coolants when just winging it like I mentioned.

As mentioned, I'm starting from just about zero knowledge of coolant; just what I've picked up from some machinists in a production facility and they just dump it in until it reads OK on the refractometer. I actually am a chemist but haven't worked as one for 16 years. None of my chemist "spidey senses" tingled at all doing what I've been doing.

Anyone know what type of setup he is running on the other side of the barrel the, to support the muzzle end I mean? Just curious on his setup if anyone knows. I'd love to give this a try on the lathes at work..

Ben

Ben

Last edited:

Assuming you are speaking of the flushing system?

Cant say for sure, but most guys are either running the GTR flushing adapter, a homemade similar style, or pipe tapping the muzzle and hard attaching a swiveling fitting. Id guess its one of the above.

Ive been using the GTR, granted I dont chamber as much as guys like Chad, but I havent had any issues other than when I forgot it was on there and decided to spin the lathe up to 1200 to chamfer the chamber edge. It just flew off pretty quick, no damage done. The pipe tap system seems pretty bulletproof, I just dont know if I want to take the extra time to do that yet being as the GTR has been working well for me. I think if you are running carbide reamers though and high RPM, there is no choice but to do something other than the GTR.

Cant say for sure, but most guys are either running the GTR flushing adapter, a homemade similar style, or pipe tapping the muzzle and hard attaching a swiveling fitting. Id guess its one of the above.

Ive been using the GTR, granted I dont chamber as much as guys like Chad, but I havent had any issues other than when I forgot it was on there and decided to spin the lathe up to 1200 to chamfer the chamber edge. It just flew off pretty quick, no damage done. The pipe tap system seems pretty bulletproof, I just dont know if I want to take the extra time to do that yet being as the GTR has been working well for me. I think if you are running carbide reamers though and high RPM, there is no choice but to do something other than the GTR.

I'm sorry I mean what is supporting the muzzle end? That is inside the spindle. I'm sorry should have been more clear.

Ben

Ben

That HAAS TL-1 Seems to be the standard for CNC lathes when it comes to gunsmithing. Everyone in a while I see one pop up for 5-7K. One of these years I might buy it.

That HAAS TL-1 Seems to be the standard for CNC lathes when it comes to gunsmithing. Everyone in a while I see one pop up for 5-7K. One of these years I might buy it.

You must live in a much more machine rich environment than I do here in California. I've had my eyes open for a few years now from LA to Redding and San Francisco to Reno and haven't seen one I would even consider going out of my way to look at for under $18k. Even at in the $18k range, they looked like they had been through hell. I suppose if one visits all the auctions, maybe more are around closer to what you are seeing them at.

Here's one for only $31k Haas TL-1 CNC Lathe, 2009

When you start looking a several year old TL-1 in the $30k+ range, you are getting really close to the budget of a "real" turning center of that vintage. I've been looking into this for a couple years now. I was a wire transfer away from spending $44k+ on a new TL-1 when my gut told me "no".

The only benefit I can see at this point of a TL-1 is being able to run it off of single phase power. Converting single phase garage power to power a 67FLA three phase turning center is getting really expensive, really quick.

I've never used a Haas TL1. My neighbor has one (purchased new about a year or so ago) and they immediately began to complain about it.

For a one off type job it may be the cats ass. However for the same price of a new TL-1 you can pick up a used self contained turning center that will offer significant force multiplication. Some glaring examples:

1. A turret with multiple stations over a single tool post

2. Hydraulic tail stock

3. Powerful controls (FANUC being my personal favorite)

4. Fully contained unit, less mess to contend with

5. Upgrades later like a bar feeder

6. A rigid clamped tail stock instead of one that pins into place and rattles back and forth till you load the center/drill chuck. (WTF Haas?)

Keep in mind. This isn't my gripe. These are comments from two brothers that own a rather impressive machine shop and possess a great deal of practical experience with manufacturing and machinery. (all firearms related) They use the TL1 for stuff, but its for 2nd op work on production jobs and/or one offs for little piss ant things they need done in the shop. Never seen it used for big jobs of any quantity.

If you stick with this gun game you'll soon discover that a product line does a whole lot towards getting bills paid and keeping cash circulating through your business. -regardless of the level that you play at. This is where automation shines because you can make stuff a whole lot faster/cheaper/better than "fat fingering" away on a manual/tool room grade piece of gear.

There's often been this long standing argument about cnc failing to replicate the QC/accuracy level that a manual machine will hold. It's bullshit and originates from those who can't/don't understand it. So they attempt to invoke fear into the minds of others as a result.

-A TL type lathe often means it has a conversational package on it cause the tool room guys often can't/won't write code. (and lathe code is stupid easy for 99.9% of the things were doing) A production machine won't have this "speak and spell" cnc option because they manufacturer expects you to know what your doing with code. FWIW the machines are often made to a higher standard because it has to hold tolerance for thousands of hours and hundreds of thousands of parts. A turning center can last 20+ years if its maintained well.

These are the same caliber of machines you trust you life to every time you fly, train, ship, drive, etc... To say they aren't as accurate is just absurd.

You can thread and chamber on a standard turning center. I've done it almost every day for the last 5 years. I've used "Tool Room" lathes and decided that ultimately they suck ass because you can't do much more than fit barrels and its still a lethargic process.

Remember. Time IS money. If your fooling yourself into thinking that in order to do a good job on a barrel you have to spend half a day on it, your only setting yourself up to fail.

I struggled long and hard deciding which machine to buy. Bantering back and forth the pros/cons of each. Robert (300 Sniper) and I have talked off/on for over a year about a machine that'll suit his needs. He finally bit the bullet and picked one up Hopefully he got a good one and not a lemon. I'm confident he'll do well because "Bert" is one smert muthah.

Don't be afraid to break out and try something different than what you see here day in, day out. There's money to be made with automation. With a little creative programming and a good understanding of what your trying to do, you CAN fit a barrel to a receiver using a CNC turning center with very little drama and accuracy/repeatability that'll exceed anything anyone's ever attempted to do with manual equipment.

That statement is sure to open a can of worms, let me clarify before the sabers start rattling. We can chamber 20+ barreled actions a day if we have to. One guy does this. They all thread on the receiver beautifully, they all HS, the chambers are concentric and have a surface finish that's to die for. The fit/finish of the threading is exceptional with burr free leading edges and flank surfaces. Do the math. Average price out there to hang a stick is $300 bucks for any marquee shop. 6 grand in labor in one day sure makes life a little easier.

NO ONE on earth is going to get that far in a single day on a manual machine. It'll never happen.

So, if your so inclined, dive in and go balls deep. The 30-40K you spend on the machine quickly goes back into your wallet. If it doesn't, your doing it wrong.

There's money to be made in this game. Don't let anyone tell you otherwise.

Good luck with your decisions and aspirations.

C.

For a one off type job it may be the cats ass. However for the same price of a new TL-1 you can pick up a used self contained turning center that will offer significant force multiplication. Some glaring examples:

1. A turret with multiple stations over a single tool post

2. Hydraulic tail stock

3. Powerful controls (FANUC being my personal favorite)

4. Fully contained unit, less mess to contend with

5. Upgrades later like a bar feeder

6. A rigid clamped tail stock instead of one that pins into place and rattles back and forth till you load the center/drill chuck. (WTF Haas?)

Keep in mind. This isn't my gripe. These are comments from two brothers that own a rather impressive machine shop and possess a great deal of practical experience with manufacturing and machinery. (all firearms related) They use the TL1 for stuff, but its for 2nd op work on production jobs and/or one offs for little piss ant things they need done in the shop. Never seen it used for big jobs of any quantity.

If you stick with this gun game you'll soon discover that a product line does a whole lot towards getting bills paid and keeping cash circulating through your business. -regardless of the level that you play at. This is where automation shines because you can make stuff a whole lot faster/cheaper/better than "fat fingering" away on a manual/tool room grade piece of gear.

There's often been this long standing argument about cnc failing to replicate the QC/accuracy level that a manual machine will hold. It's bullshit and originates from those who can't/don't understand it. So they attempt to invoke fear into the minds of others as a result.

-A TL type lathe often means it has a conversational package on it cause the tool room guys often can't/won't write code. (and lathe code is stupid easy for 99.9% of the things were doing) A production machine won't have this "speak and spell" cnc option because they manufacturer expects you to know what your doing with code. FWIW the machines are often made to a higher standard because it has to hold tolerance for thousands of hours and hundreds of thousands of parts. A turning center can last 20+ years if its maintained well.

These are the same caliber of machines you trust you life to every time you fly, train, ship, drive, etc... To say they aren't as accurate is just absurd.

You can thread and chamber on a standard turning center. I've done it almost every day for the last 5 years. I've used "Tool Room" lathes and decided that ultimately they suck ass because you can't do much more than fit barrels and its still a lethargic process.

Remember. Time IS money. If your fooling yourself into thinking that in order to do a good job on a barrel you have to spend half a day on it, your only setting yourself up to fail.

I struggled long and hard deciding which machine to buy. Bantering back and forth the pros/cons of each. Robert (300 Sniper) and I have talked off/on for over a year about a machine that'll suit his needs. He finally bit the bullet and picked one up Hopefully he got a good one and not a lemon. I'm confident he'll do well because "Bert" is one smert muthah.

Don't be afraid to break out and try something different than what you see here day in, day out. There's money to be made with automation. With a little creative programming and a good understanding of what your trying to do, you CAN fit a barrel to a receiver using a CNC turning center with very little drama and accuracy/repeatability that'll exceed anything anyone's ever attempted to do with manual equipment.

That statement is sure to open a can of worms, let me clarify before the sabers start rattling. We can chamber 20+ barreled actions a day if we have to. One guy does this. They all thread on the receiver beautifully, they all HS, the chambers are concentric and have a surface finish that's to die for. The fit/finish of the threading is exceptional with burr free leading edges and flank surfaces. Do the math. Average price out there to hang a stick is $300 bucks for any marquee shop. 6 grand in labor in one day sure makes life a little easier.

NO ONE on earth is going to get that far in a single day on a manual machine. It'll never happen.

So, if your so inclined, dive in and go balls deep. The 30-40K you spend on the machine quickly goes back into your wallet. If it doesn't, your doing it wrong.

There's money to be made in this game. Don't let anyone tell you otherwise.

Good luck with your decisions and aspirations.

C.

Last edited:

Wow Chad, 20 barrels a day is impressive by any ones standards. I can't even imagine one man doing the set up on 20 barrels in one day let alone all of the rest, that truly is amazing. I am wondering how you handle the muzzle end of the barrel in the machining center. The TL-1 is enough like a conventional lathe that a spider is used on that end but I am assuming that the machining center is to long to handle the barrel conventionally so I am curious what you are doing.

I don't think any one can argue with your results so if you don't mind sharing I would learn a little here.

Thanks Gary

I don't think any one can argue with your results so if you don't mind sharing I would learn a little here.

Thanks Gary

I wish I had some machining experience and was able to work for someone like Chad for a few years. The knowledge that he shares here on the 'hide is pretty impressive but I can only imagine some of the tricks his employees get to learn working with him.

Similar threads

Sidearms & Scatterguns

Sig just can't get out of their own way

- Replies

- 11

- Views

- 783

- Replies

- 3

- Views

- 281