For those of you that read my earlier thread on the troubles that I experienced with throwing charges of IMR4064, you may remember that I was attempting to recreate the FGGM 168 SMK load. Like (what I like to think is) many people, I occasionally get a "flier" in a group that is otherwise very good. Not a called "whoops, I really shouldn't have let that one go" but more of a "why the hell is that THERE?" kind of flier. Anyway, looking for ways to improve my loads and my shooting, I started researching runout. I had heard of runout before but, I had relegated the measurement and elimination of runout to "benchrest stuff." You know, Nth degree stuff like sorting brass by the volume of 100% ethanol that each case holds, sorting bullets to the 0.1 grain, sorting bullets by base to ogive distance, and trimming meplats. Surely, one or 2 THOUSANDTHS of an inch in concentricity can't have an effect on the meager and amateurish shooting that I do... Anyway, I had 70 of my FGMM "clones" sitting in the closet with nothing to do- and I found a few dollars in another closet- so, I went to the local gun shop and purchased an RCBS Master Case Gauge and started measuring case neck and bullet runout. Now, all of these cases were once fired through my lr308 and had been sized on my RCBS press with the standard "green box" RCBS dies. Measuring case neck runout, I had a "normal" distribution with a peak at 0.002 and a tail that extended to 0.005.

Runout....Number

0.001.....13

0.002.....27

0.003.....21

0.004......9

0.005......7

The bullet runout for the 0.001 group ranged as high as 0.002 and for the 0.005 group ranged from 0.005 to 0.007.

In addition to those loaded rounds, I have 5 100 boxes of lapua brass in 4 different lots, 0ne box of which has been shot through my Lr 308. Of these, 30% measured 0.001 (or less), 50% were binned at 0.002 (more than ~0.0015 but less than 0.0025), and 94 (20%) were binned as 0.003 or greater. These measurements were all taken after the cases were run through my dies, as some of the case mouths needed rounding.

Given the above observations, here is the first experiment.

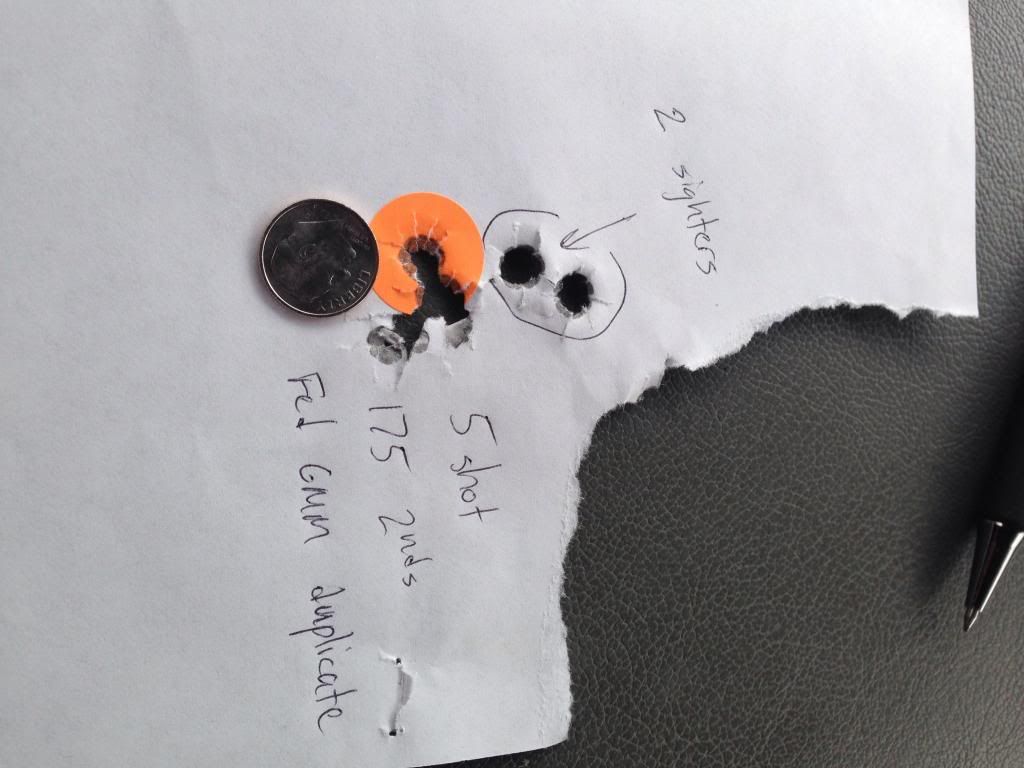

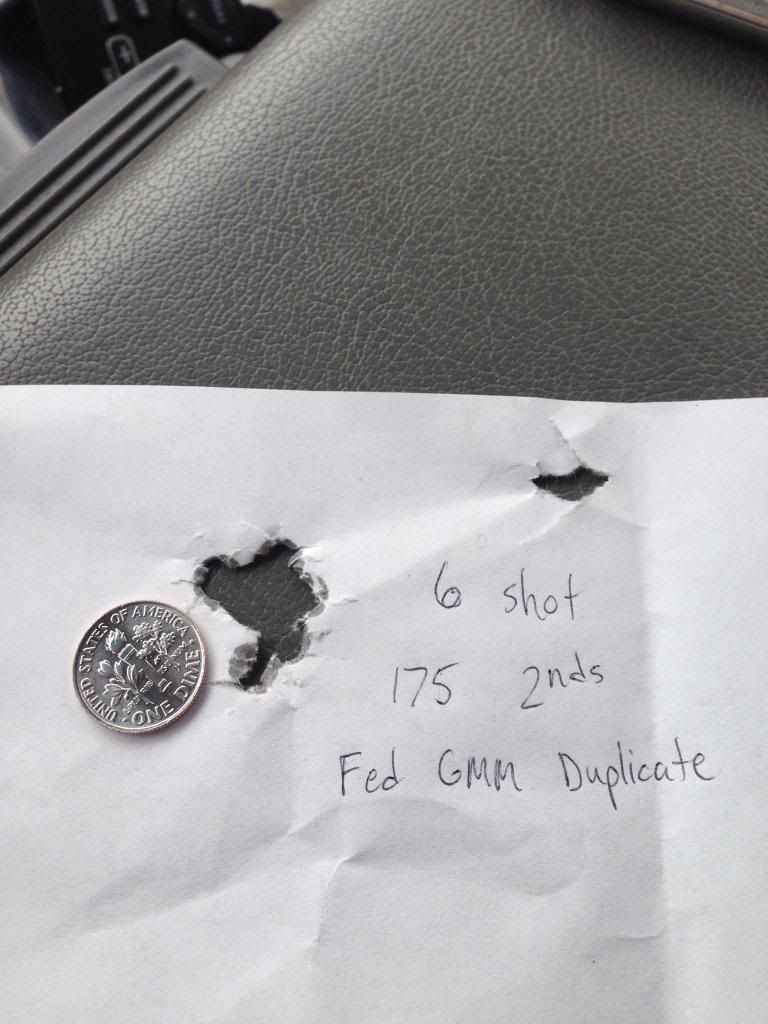

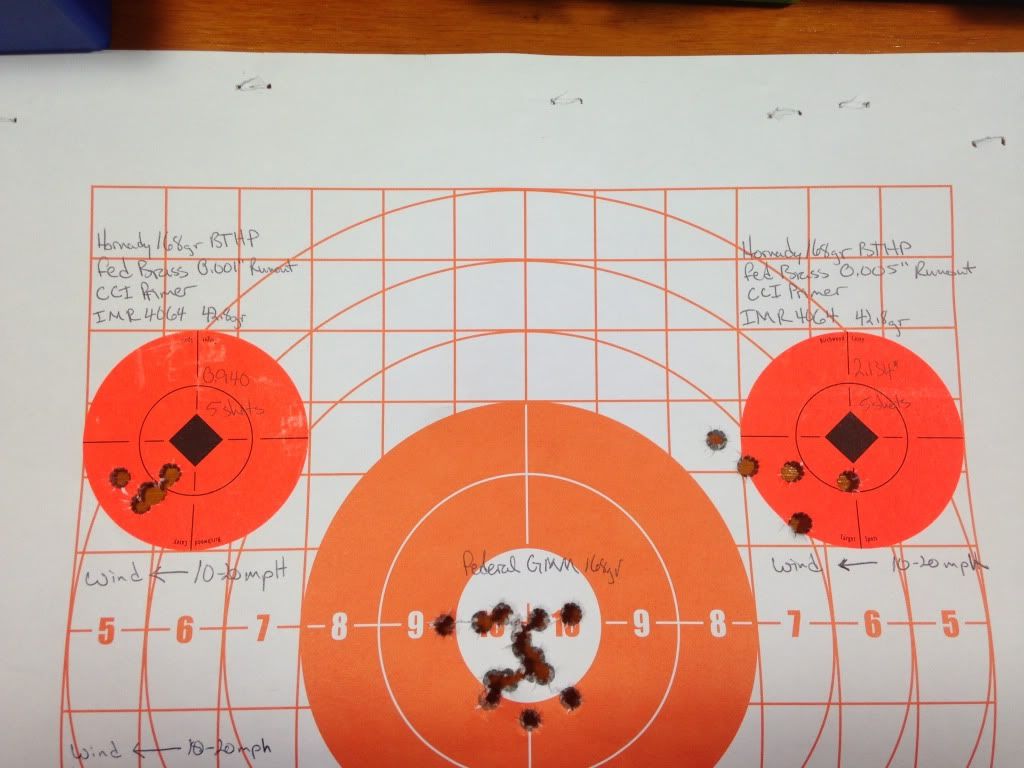

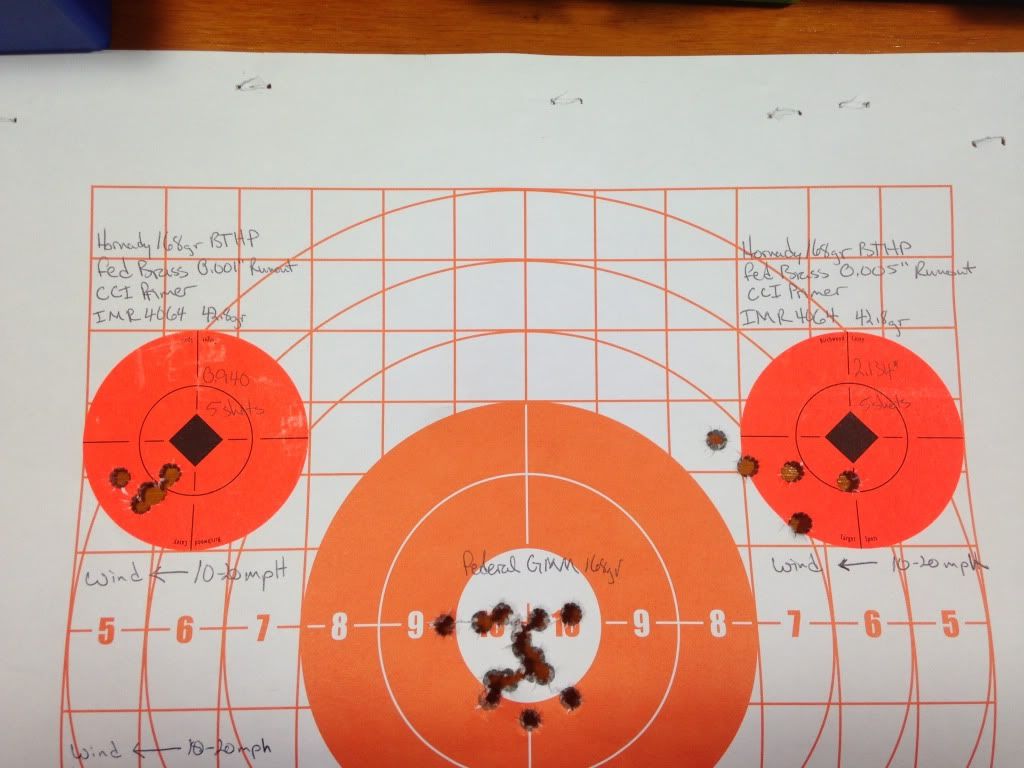

I took 5 "random" cartridges from the 0.001 case neck runout group and shot them against 5 cartridges from the 0.005 case neck runout group. Surely, this small difference will not affect my precision- especially from a budget gas gun...

Measurements are outside edge to outside edge. The FGMM was used for functional adjustment of my gas block, so do not pay attention to that "group."

That was the hope anyway. Looks like I need to start paying attention to runout. But, I may have found a cause for at least some of those unexplained fliers...

Do you measure runout?

If so, where do you draw the line on what is acceptable to shoot "for score" (whatever score you may be keeping)?

Do you have empirical evidence for picking ths cutoff?

Is there a way of correcting case neck and/or bullet runout?

I have seen the Hornady runout tool. If you have used it, how well does it work?

Now to the second set of observations. Remember that I said that 100 of those lapua brass had been through my gun? Ok, follow me on this. Out of 500 brass, 94 had a measured runout of 0.003 or greater. Of those, 10 had a runout of 0.004 or greater. Of those 94, only 10 had been previously shot, and none of those 10 measured greater than 0.003. So, 84 out of 400 unfired brass were 0.003 or greater (21%) and 10 out of 100 previously fired brass were 0.003 (10%).

Hypothesis- Shooting a cartridge causes the brass to expand to the dimensions of the chamber of the gun in which it was fired. Ok, we know this. But, this expansion allows the resizing die to better do its job (because there is some brass to move) and align the case neck with the case body- in addition to getting everything back down to unfired size specifications.

Any thoughts? Unfortunately, I cannot rule out lot to lot variability of the unfired brass, as i did not take any runout measurements of the "shot" group when it was still unfired. Aswell, I do not have any more from that lot. And, I haven't shot any from the other lots to test the hypothesis that blowing out the case allows the sizing die to improve concentricity.

Note- I was able to shrink the runout for the 0.004 group by running them through the dies again, but it was not a huge gain. They were able to be binned with the 0.003 group.

Runout....Number

0.001.....13

0.002.....27

0.003.....21

0.004......9

0.005......7

The bullet runout for the 0.001 group ranged as high as 0.002 and for the 0.005 group ranged from 0.005 to 0.007.

In addition to those loaded rounds, I have 5 100 boxes of lapua brass in 4 different lots, 0ne box of which has been shot through my Lr 308. Of these, 30% measured 0.001 (or less), 50% were binned at 0.002 (more than ~0.0015 but less than 0.0025), and 94 (20%) were binned as 0.003 or greater. These measurements were all taken after the cases were run through my dies, as some of the case mouths needed rounding.

Given the above observations, here is the first experiment.

I took 5 "random" cartridges from the 0.001 case neck runout group and shot them against 5 cartridges from the 0.005 case neck runout group. Surely, this small difference will not affect my precision- especially from a budget gas gun...

Measurements are outside edge to outside edge. The FGMM was used for functional adjustment of my gas block, so do not pay attention to that "group."

That was the hope anyway. Looks like I need to start paying attention to runout. But, I may have found a cause for at least some of those unexplained fliers...

Do you measure runout?

If so, where do you draw the line on what is acceptable to shoot "for score" (whatever score you may be keeping)?

Do you have empirical evidence for picking ths cutoff?

Is there a way of correcting case neck and/or bullet runout?

I have seen the Hornady runout tool. If you have used it, how well does it work?

Now to the second set of observations. Remember that I said that 100 of those lapua brass had been through my gun? Ok, follow me on this. Out of 500 brass, 94 had a measured runout of 0.003 or greater. Of those, 10 had a runout of 0.004 or greater. Of those 94, only 10 had been previously shot, and none of those 10 measured greater than 0.003. So, 84 out of 400 unfired brass were 0.003 or greater (21%) and 10 out of 100 previously fired brass were 0.003 (10%).

Hypothesis- Shooting a cartridge causes the brass to expand to the dimensions of the chamber of the gun in which it was fired. Ok, we know this. But, this expansion allows the resizing die to better do its job (because there is some brass to move) and align the case neck with the case body- in addition to getting everything back down to unfired size specifications.

Any thoughts? Unfortunately, I cannot rule out lot to lot variability of the unfired brass, as i did not take any runout measurements of the "shot" group when it was still unfired. Aswell, I do not have any more from that lot. And, I haven't shot any from the other lots to test the hypothesis that blowing out the case allows the sizing die to improve concentricity.

Note- I was able to shrink the runout for the 0.004 group by running them through the dies again, but it was not a huge gain. They were able to be binned with the 0.003 group.