Since my Ladder test was probably botched due to a loose scope rail and possibly barrel I decided to take everything apart and take a look at things. I have never owned a rifle, so I'll take any advice that an experienced owner would like to give.

The rail was loose at the front. I'm not sure what to to. We put blue locktite on the screws when I first got it, but I'm thinking there was oil or something that caused issues. There was oil under the rail (I assume from cleaning) and on the screws.

I want to replace the factory rail with a 20-30 MOA rail. Any ideas? This one doesn't look to be holding up really well to the abuse of the 338LM.

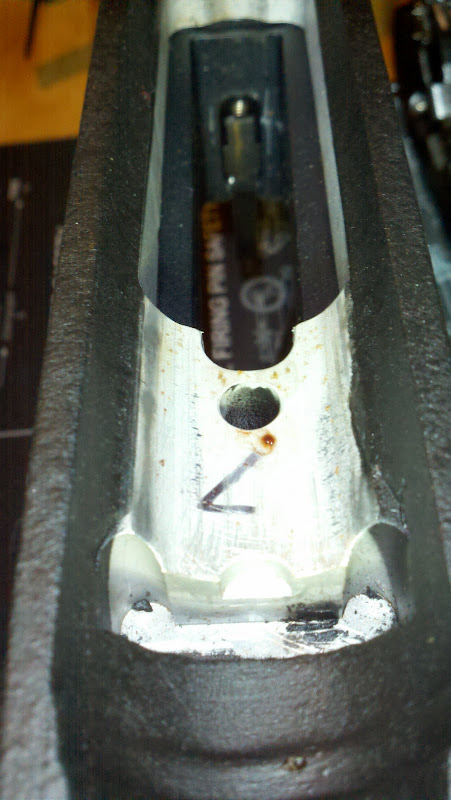

The front barrel bolt was not what I would call tight. Came loose quite easily. I'm wondering if it was about to be completely loose.

Do these pictues show anything amiss?

Should the front barrel bolt be touching the accustock inside the bolt hole?

Thanks for all advice. If something here is wrong PLEASE point it out because I've wasted enough rounds already trying to get this thing up and running correctly. If I need to send it to have some work done to solve an issue I'll do it. I'd rather use the money now to fix something than to blow more ammo down range to find it later.

Full size pictures can be found at the link below.

https://picasaweb.google.com/rexweatherford/LadderTest?authuser=0&feat=directlink

The rail was loose at the front. I'm not sure what to to. We put blue locktite on the screws when I first got it, but I'm thinking there was oil or something that caused issues. There was oil under the rail (I assume from cleaning) and on the screws.

I want to replace the factory rail with a 20-30 MOA rail. Any ideas? This one doesn't look to be holding up really well to the abuse of the 338LM.

The front barrel bolt was not what I would call tight. Came loose quite easily. I'm wondering if it was about to be completely loose.

Do these pictues show anything amiss?

Should the front barrel bolt be touching the accustock inside the bolt hole?

Thanks for all advice. If something here is wrong PLEASE point it out because I've wasted enough rounds already trying to get this thing up and running correctly. If I need to send it to have some work done to solve an issue I'll do it. I'd rather use the money now to fix something than to blow more ammo down range to find it later.

Full size pictures can be found at the link below.

https://picasaweb.google.com/rexweatherford/LadderTest?authuser=0&feat=directlink