I had a request for silencer designs suitable to make on a hobby lathe, so I thought I would post a few of my drawings. For those live in the USA so the only way to make a silencer here without a license is to submit the ATF form 1 (Application to Make and Register a Firearm). The forms can be ordered from the ATF homepage, but it takes a few months to get them as they are running behind since the great demand on their time caused by the last election. The ATF form 1 available from http://www.titleii.com/TitleII.com/Welcome.html is the old revision. I heard they are still accepting them until the new revision is available online at the ATF homepage. I sent one in a few weeks ago, hopefully if it is rejected, they will send me the new forms to fill out and send in again.

It is important to remember that you can not start to make parts until the ATF form 1 is returned approved with the canceled $200 tax stamp attached. Once the silencer is made, parts can not be replaced, the bore changed or the length increased by the person it is registered to, unless another $200 tax is paid or it is sent to an SOT class 2 for repairs. It is also illegal to have replacement parts on hand or to change out worn parts except for wipes; the hard rubber disks used in some designs. There are letters from the ATF on the Subguns website that address some of these problems and the ATF also has a silencer FAQ.

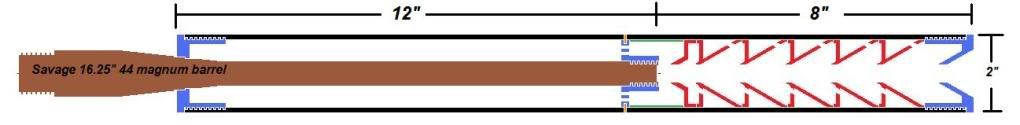

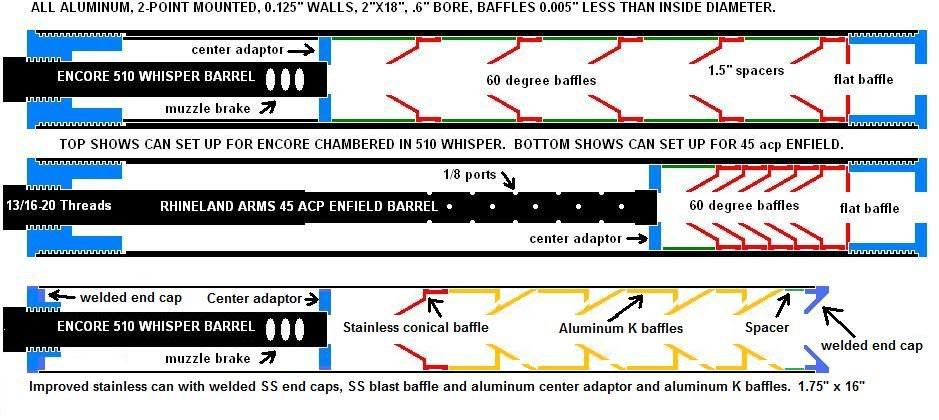

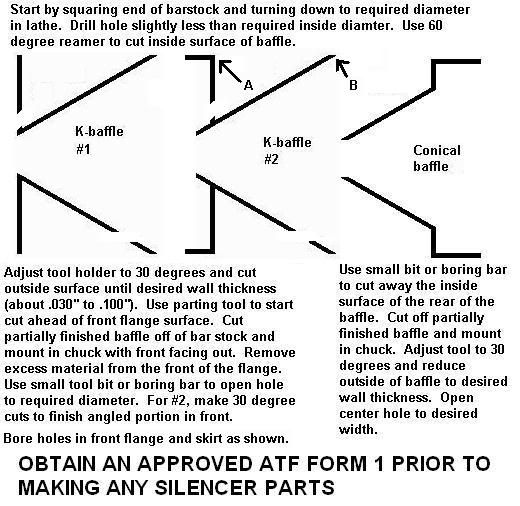

This is a 510 whisper silencer for a TC Encore. It telescopes over the barrel about six inches. This makes for a very sturdy mount and aligns with the bore very well as long as the barrel is a good straight one. The middle drawing shows it set up for an Enfield in 45 acp. The lower drawing is how I would have made it from steel if I was only using jacketed bullets and had more experience with silencer design.

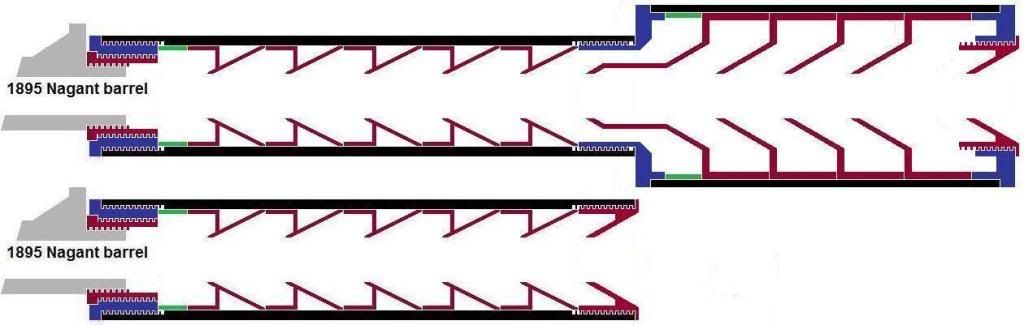

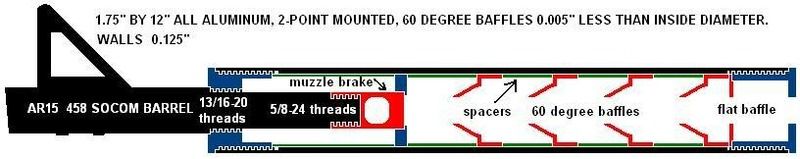

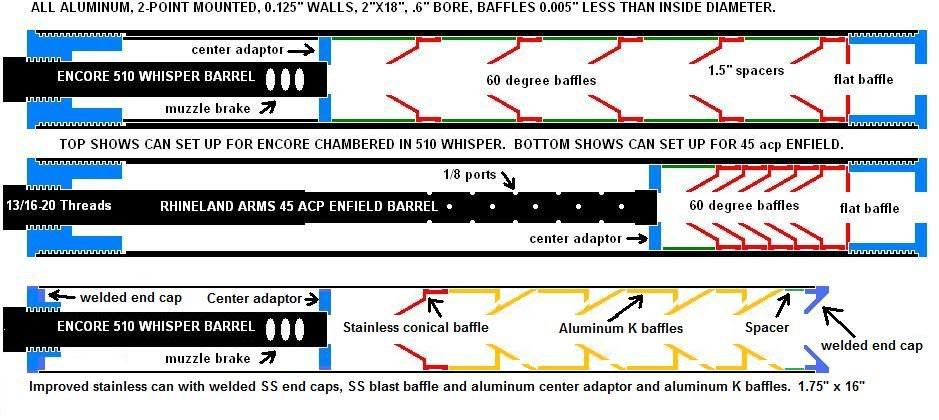

Here is a drawing for an ar-15 silencer. I did not want to telescope the can over the barrel and I thought that the ½-28 threads for the flash suppressor were rather small for mounting a can. I machined a muzzle brake to fit back over the barrel for a snug fit and stay aligned well to the bore. The silencer attaches to the brake at two points and is held in place by 13/16-20 threads.

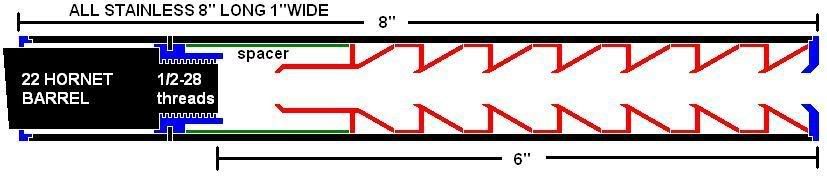

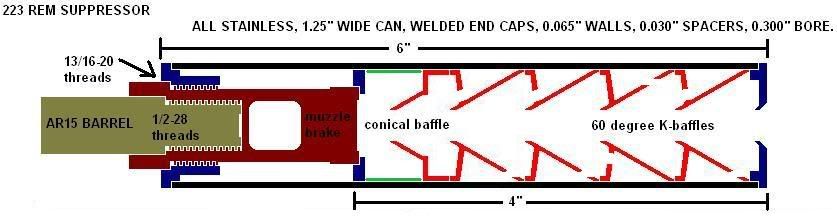

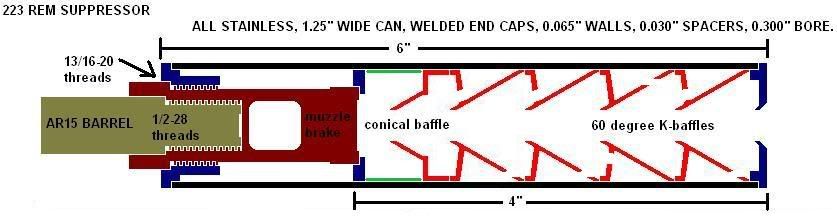

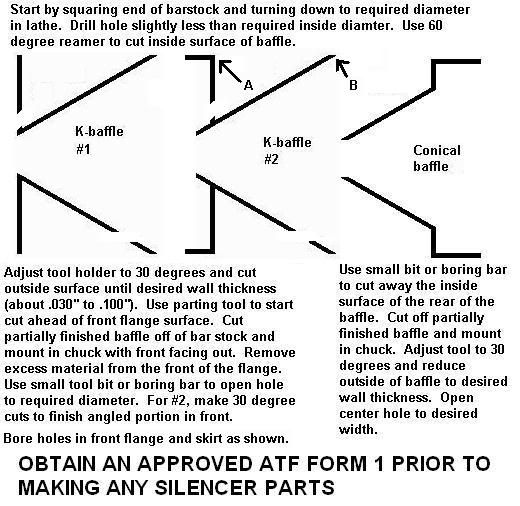

Here is a drawing with simple instructions on how to make a baffle. There is a tutorial on the Silencer Talk forum with photos showing the steps for making a baffle on the lathe.

If anyone has ideas for silencers, I would like to see them. I learned to operate a metal lathe while making my first silencer for a 300 whisper and am always ready to learn more. Thanks.

Ranb

It is important to remember that you can not start to make parts until the ATF form 1 is returned approved with the canceled $200 tax stamp attached. Once the silencer is made, parts can not be replaced, the bore changed or the length increased by the person it is registered to, unless another $200 tax is paid or it is sent to an SOT class 2 for repairs. It is also illegal to have replacement parts on hand or to change out worn parts except for wipes; the hard rubber disks used in some designs. There are letters from the ATF on the Subguns website that address some of these problems and the ATF also has a silencer FAQ.

This is a 510 whisper silencer for a TC Encore. It telescopes over the barrel about six inches. This makes for a very sturdy mount and aligns with the bore very well as long as the barrel is a good straight one. The middle drawing shows it set up for an Enfield in 45 acp. The lower drawing is how I would have made it from steel if I was only using jacketed bullets and had more experience with silencer design.

Here is a drawing for an ar-15 silencer. I did not want to telescope the can over the barrel and I thought that the ½-28 threads for the flash suppressor were rather small for mounting a can. I machined a muzzle brake to fit back over the barrel for a snug fit and stay aligned well to the bore. The silencer attaches to the brake at two points and is held in place by 13/16-20 threads.

Here is a drawing with simple instructions on how to make a baffle. There is a tutorial on the Silencer Talk forum with photos showing the steps for making a baffle on the lathe.

If anyone has ideas for silencers, I would like to see them. I learned to operate a metal lathe while making my first silencer for a 300 whisper and am always ready to learn more. Thanks.

Ranb