Having had multiple barrels from PVA and including ones with can brake adapters and all of them threaded I can tell you you're talking out your ass. I have also been in this game a long time and have had many rifles and know quality work and PVA does quality work. Can a bad one get through? Sure happens to every smith but it's far from the norm.It's not just the crown... It's probably the threads, as well. I'd just make them buy you a new barrel and refund labor, and have another smith install the new one. Obviously, PVA's machinists suck, and it seems their CS is terrible, too, if you can't get in touch with them. Regardless, just on those 2 strikes alone, I'd be finding me a new smith.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Suppressors Solved: Area 419 Adapter and TBAC Ultra9 Strike!

- Thread starter GBMaryland

- Start date

Not only that, Rob, but @bohem jumped right on it, shipping label sent, and it’s already on its way back to PVA.Having had multiple barrels from PVA and including ones with can brake adapters and all of them threaded I can tell you you're talking out your ass. I have also been in this game a long time and have had many rifles and know quality work and PVA does quality work. Can a bad one get through? Sure happens to every smith but it's far from the norm.

Everybody and every company has a quality issue get out once in a while. It’s how that person or company reacts to make it right that’s the differentiator. Hard to ask for more.

And we should all keep in mind that’s it’s still uncertain if this is PVA’s error, 419’s error, or a combo of both.

@GBMaryland has both the barrel and adapter on its way back and I feel certain that Josh will soon come back with some clarity on the root cause.

And we should all keep in mind that’s it’s still uncertain if this is PVA’s error, 419’s error, or a combo of both.

I was going to mention that but figured most saw it in reading the post.

Haha…..yeah but I am:I was going to mention that but figured most saw it in reading the post.

Lol

That’s why I haven’t chimed in… At this point it’s anyone’s guess as to what’s causing this issue.

Yes, it appears that with both the TBAC and the 419 devices the barrel mating surface is not perfectly perpendicular to the bore. The issue is less pronouced with the TBAC brake and more so with the 419, but we have yet to determine why any if that is.

PVA will get the barreled action tomorrow, and hopefully we’ll find out whats up.

Yes, it appears that with both the TBAC and the 419 devices the barrel mating surface is not perfectly perpendicular to the bore. The issue is less pronouced with the TBAC brake and more so with the 419, but we have yet to determine why any if that is.

PVA will get the barreled action tomorrow, and hopefully we’ll find out whats up.

I did a test on the AREA 419 Hellfire suppressor mount for the thunder beast ultra 7. What I did was chucked up a piece in the lathe and turned threads and a shoulder on it and left in the lathe so everything stays true and square to the lathe. Then screwed the TBAC CB ultra on the one that came with the ultra 7 and ran indicator on the id bore of suppressor. The total indicator run out was .0025 or .00125 out of center which is amazing. I took it on and off several times was very consistent. I put the AREA 419 hellfire suppressor mount on the same threaded shoulder and the runout was .034 total indicator run out. I sent area419 an email and they sent me another hellfire adapter so I recut threads and shoulder in lathe and did same test. This time the runout was worse as it was to much for my indicator to read guessing around .045-.055 of total run out. I then ran the indicator on the taper of hellfire adapter which was .005 total indicator run out. Then to prove out my setup on my second test since I had recut the threads I put the TBAC CB ultra adapter and ultra 7 back on and it ran .003 TIR which is .0005 different than the last time I tested it which is exceptional accuracy. I am now waiting for AREA 419 to send me another Hellfire suppressor mount to run the test on and determine if I will keep them. In defense of PVA threading of the barrel what you are seeing in the pictures that were posted is the threads and shoulder are cut correctly. What you are seeing is the out side diameter of the barrel is not concentric to the bore which is what they would have indicated off of so when they chamfered the shoulder it only touched on one side. I will now be testing more of these in the future before I trust the concentricity. Both of these I tested would have produced a baffle strike on a 9" can shooting 30 cal. I tried to down load the videos but can only post pictures. If anyone knows how to view video let me know. I have a video of each process and set up that shows run out.

Need to post the vid to YouTube and then site will accept that link.I did a test on the AREA 419 Hellfire suppressor mount for the thunder beast ultra 7. What I did was chucked up a piece in the lathe and turned threads and a shoulder on it and left in the lathe so everything stays true and square to the lathe. Then screwed the TBAC CB ultra on the one that came with the ultra 7 and ran indicator on the id bore of suppressor. The total indicator run out was .0025 or .00125 out of center which is amazing. I took it on and off several times was very consistent. I put the AREA 419 hellfire suppressor mount on the same threaded shoulder and the runout was .034 total indicator run out. I sent area419 an email and they sent me another hellfire adapter so I recut threads and shoulder in lathe and did same test. This time the runout was worse as it was to much for my indicator to read guessing around .045-.055 of total run out. I then ran the indicator on the taper of hellfire adapter which was .005 total indicator run out. Then to prove out my setup on my second test since I had recut the threads I put the TBAC CB ultra adapter and ultra 7 back on and it ran .003 TIR which is .0005 different than the last time I tested it which is exceptional accuracy. I am now waiting for AREA 419 to send me another Hellfire suppressor mount to run the test on and determine if I will keep them. In defense of PVA threading of the barrel what you are seeing in the pictures that were posted is the threads and shoulder are cut correctly. What you are seeing is the out side diameter of the barrel is not concentric to the bore which is what they would have indicated off of so when they chamfered the shoulder it only touched on one side. I will now be testing more of these in the future before I trust the concentricity. Both of these I tested would have produced a baffle strike on a 9" can shooting 30 cal. I tried to down load the videos but can only post pictures. If anyone knows how to view video let me know. I have a video of each process and set up that shows run out.

Thanks for this info since I too have the 419 Hellfire system sitting on the bench waiting for the can to get out of jail.

In my limited experience, everything I’ve seen from 419 has been first class, top shelf, stuff.

Last edited:

I will try that tomorrow afternoon/evening. ThanksNeed to post the vid to YouTube and then site will accept that link.

Thanks for this info even though it’s a bit distressing since I too have the 419 Hellfire system sitting on the bench waiting for the can to get out of jail.

What an odd deal. I've been running the area 419 CB adapter setup on my ultra 9 for a couple years now and have yet to have any weird POI shifts, baffle strikes, etc etc, on a whole range of barrels from my 22GT to several 308 barrels I've had. As previously mentioned, max POI shift with just the adapter vs with the can and everything was a couple tenths of a mil. I was planning on running the exact same setup on a magnus but ended up changing to the SR version as it's more cooler and TBAC has a non directional SR brake out now.

Good to see good comms from all the companies involved in this

Good to see good comms from all the companies involved in this

Wow, waiting to hear the final verdict on this one. I'm sitting here thinking I have almost the exact same setup PVA 6.5 barrel, and Area 419 adapters except mine is the Ultra 9 .30. But then thinking some more on it the last time I used my can was on my cheap PSA PX10 .308 with the Area 419 adapters.

I can't say anything about shift as I zeroed in a new scope on it as well and only shot it suppressed. I just shot some 168/175 loads I put together quickly in primed LC brass. First time this cheapo shot MOA.

I can't say anything about shift as I zeroed in a new scope on it as well and only shot it suppressed. I just shot some 168/175 loads I put together quickly in primed LC brass. First time this cheapo shot MOA.

Yeah, this is a TRG-22 with a Bartlein 6.5 SS barrel in a Vision chassis.

It’s a shooter in its current configuration… minus the suppressor alignment issue.

PVA did a great job with the turn around on all of it.

I have to admit I really curious to find out what the deal is.

I can tell you that I will never install a supressor without using a witness rod again.

It’s a shooter in its current configuration… minus the suppressor alignment issue.

PVA did a great job with the turn around on all of it.

I have to admit I really curious to find out what the deal is.

I can tell you that I will never install a supressor without using a witness rod again.

It's possible that there's something wrong with a batch of parts or even just a handful inside of a batch. Your parts from a few years ago might well be fine and there's something wrong with a handful in a later batch. It might be as simple as a chip was caught in the pick-off collet during manufacturing and one or a handful of parts got messed up. Things happen.What an odd deal. I've been running the area 419 CB adapter setup on my ultra 9 for a couple years now and have yet to have any weird POI shifts, baffle strikes, etc etc, on a whole range of barrels from my 22GT to several 308 barrels I've had. As previously mentioned, max POI shift with just the adapter vs with the can and everything was a couple tenths of a mil. I was planning on running the exact same setup on a magnus but ended up changing to the SR version as it's more cooler and TBAC has a non directional SR brake out now.

Good to see good comms from all the companies involved in this

It's possible we screwed up, well it would be me who screwed up as I'm the one who cut the barrel for GB. So it's possible I screwed up. It's also possible it's not our fault at all based on some evidence we see in the photos and what Westbound found. He sent me videos to see and it's something that I'm sure 419 will address. They're good about taking care of stuff.

The all TBAC part stackup looks fine. Though I'll be sure to check the shoulder and let @Zak Smith know if his summary diagnosis was right or wrong.

There's no light gap coming through the shoulder on one side of the barrel vs the other which is a dead giveaway when the shoulder it crooked. OD chamfer is not a valid indicator... ever. More OD chamfer on one side vs the other doesn't mean anything for how concentric the threads are to the bore. We cut barrel contours in such a manner that it's less likely to happen on our stuff than on other contours and this was a barrel supplied by the customer. ID/OD relationship is virtually never true, which is why the well known practice is to dial in the bore not the OD. Again though, it's possible I made a mistake.

This is why we sent a call tag out to @GBMaryland yesterday and the barreled action will be back here tomorrow. Which puts it back out of our shop on Friday or at the latest Monday.

Even if it's not our fault the root cause still needs to be addressed. It sounds like @Westbound found something that might be a broader concern than just how badly someone in a bad mood thinks my machine work sucks.

Last edited:

IMO, its is both too early yet to tell where the fault lies and for that fella to cast any aspersions. That, and all three companies involved have engaged positively, openly, and I feel confident that we will surely have a root cause confirmed this week by Josh.might be a broader concern than just how badly someone in a bad mood thinks my machine work sucks.

I do hope @Westbound puts his vids up on YouTube or some other site whose link's SH accepts. Love to see them. @Westbound, did you send those vids to Area 419 and perhaps send the part(s) back for them to examine or did you just chat with them about your results? Any reply or response?

But, in fairness, there are also vids posted to SH by @Supersubes where he found runout with the Area 419 Hellfire system to be very excellent (if I remember correctly, .005 total on a 9" can) and he too did exactly as @Westbound and did his measurements with the freshly threaded barrel still in the lathe. Link below.

Suppressors - Area 419 suppressor adapter straightness with an EA Lux 6.5.

I threaded a muzzle today and decided to take a short video while the barrel was still dialed into the lathe to measure runout and repeatability. I used the Energetic Armament Lux 6.5, a Titanium Area 419 suppressor adapter, and a Area 419 Universal adapter. There’s a potential for a large...

So, it seems to me that in any and all cases there is no justification (at least not at this point) for any general condemnation of any company, person, or products and that this may well be a batch/specific item issue, perhaps a VERY unfortunate stack of tolerances, or both (maybe???).

After Josh completes his examination and comes up with some findings, it would also be very interesting to see Area 419's (@flyer1a ) findings as I believe that they will have gotten part(s) back from @GBMaryland

By the by, what I know about gunsmithing and machining can be written on a match pack so take any/all input from me with a grain of salt.

Cheers

Here are the videos from Westbound. I saw this in person and we also tested my TBAC Ultra 7 can with my Area 419 adapter that I have had for about a year. My Area 419 adapter produced .007" runout if I recall. Just a hair more than the CB brake, but great results.

It seems the adapters Westbound and GBMaryland received are from a bad batch. Hopefully its a small run and there aren't a bunch of baffle strike threads popping up.

It seems the adapters Westbound and GBMaryland received are from a bad batch. Hopefully its a small run and there aren't a bunch of baffle strike threads popping up.

Last edited:

Here are the videos from Westbound. I saw this in person and we also tested my TBAC Ultra 7 can with my Area 419 adapter that I have had for about 2 years. My Area 419 adapter produced .007" runout if I recall. Just a hair more than the CB brake, but great results.

It seems the adapters Westbound and GBMaryland received are from a bad batch. Hopefully its a small run and there aren't a bunch of baffle strike threads popping up.

First video is showing as private can you change that so we can see? Is that first video yours that was good?

Thank you for posting this. Did @Westbound also give you the vid where he measured on the tapered face of the 419 mount.Should be fixed now. The first video is the TBAC with CB Brake.

He had the mount (part that goes into the suppressor) screwed on to the uni adapter but with no suppressor to isolate runout to the mounting system and eliminate any runout or additional tolerance stacking contributions from the can?

If so, would you consider posting that also.

Cheers

I do not have that video. I may be wrong, but I think he was saying he measured the runout on the taper of the uni adapter, not the suppressor mount.Thank you for posting this. Did @Westbound also give you the vid where he measured on the tapered face of the 419 mount.

He had the mount (part that goes into the suppressor) screwed on to the uni adapter but with no suppressor to isolate runout to the mounting system and eliminate any runout or additional tolerance stacking contributions from the can?

If so, would you consider posting that also.

Cheers

I can say we mixed and matched every combination we had from numerous CB brakes, Area 419 uni adapters, and the Area 419 suppressor mounts between the two TBAC Ultra 7s. The results consistently showed a runout issue with the two newer suppressor mounts but not with the one I had purchased about a year ago.

I think its alright for me to post it then....its up on YT but not listed under their account by a member who sent me the links.I do not have that video. I may be wrong, but I think he was saying he measured the runout on the taper of the uni adapter, not the suppressor mount.

I can say we mixed and matched every combination we had from numerous CB brakes, Area 419 uni adapters, and the Area 419 suppressor mounts between the two TBAC Ultra 7s. The results consistently showed a runout issue with the two newer suppressor mounts but not with the one I had purchased about a year ago.

This is the one I was speaking of and its def on the taper of the mount.

Wow, so....maybe a batch problem, yeah?The results consistently showed a runout issue with the two newer suppressor mounts but not with the one I had purchased about a year ago.

Yes, the taper on the universal adapter touches nothing but air when used with a suppressor adapter. The vertical shoulder is what the adapter touches.Wasn't it said in another thread that Area 419 suppressor mounts do not index off the taper?

Yes, but I believe that was Westbound is showing in the vid I posted above is NOT the adapter taper that was discussed but rather the tapered bell on the mount (with the one port break) that screws into the suppressor.Yes, the taper on the universal adapter touches nothing but air when used with a suppressor adapter. The vertical shoulder is what the adapter touches.

Am I wrong on this???

Just got off the phone with Josh at PVA… And they did a very comprehensive job checking everything out.

Since I’ll likely get everything wrong I’m gonna wait for him to post a Videos and the specific information.

I want to say that a one day turnaround time on something like this is unheard of and I really appreciate it.

Since I’ll likely get everything wrong I’m gonna wait for him to post a Videos and the specific information.

I want to say that a one day turnaround time on something like this is unheard of and I really appreciate it.

Just clicked on the vid, you're right.Yes, but I believe that was Westbound is showing in the vid I posted above is NOT the adapter taper that was discussed but rather the tapered bell on the mount (with the one port break) that screws into the suppressor.

Am I wrong on this???

We got the barreled action back this afternoon and ran some tests after taking it apart and inspecting everything.

There was a pair of clues for troubleshooting & throwing blame around early on, so an educating time for those on the thread: The runout behavior was seen on a different barrel from a different company. Chances of that happening and it being 2 screwed up barrels and not a screwed up mount are very low. Second clue: the barrel was stated to shoot 1 hole without the adapter kit installed, if the crown was so screwed up that threads were causing baffle strikes the issue would very likely cause accuracy problems as well.

One note: @GBMaryland the front action screw on your chassis is impinging on the barrel tenon, the screw is about 1 thread too long. See below, there's a nasty ding in the corner of the barrel tenon where the action screw is driving into it.

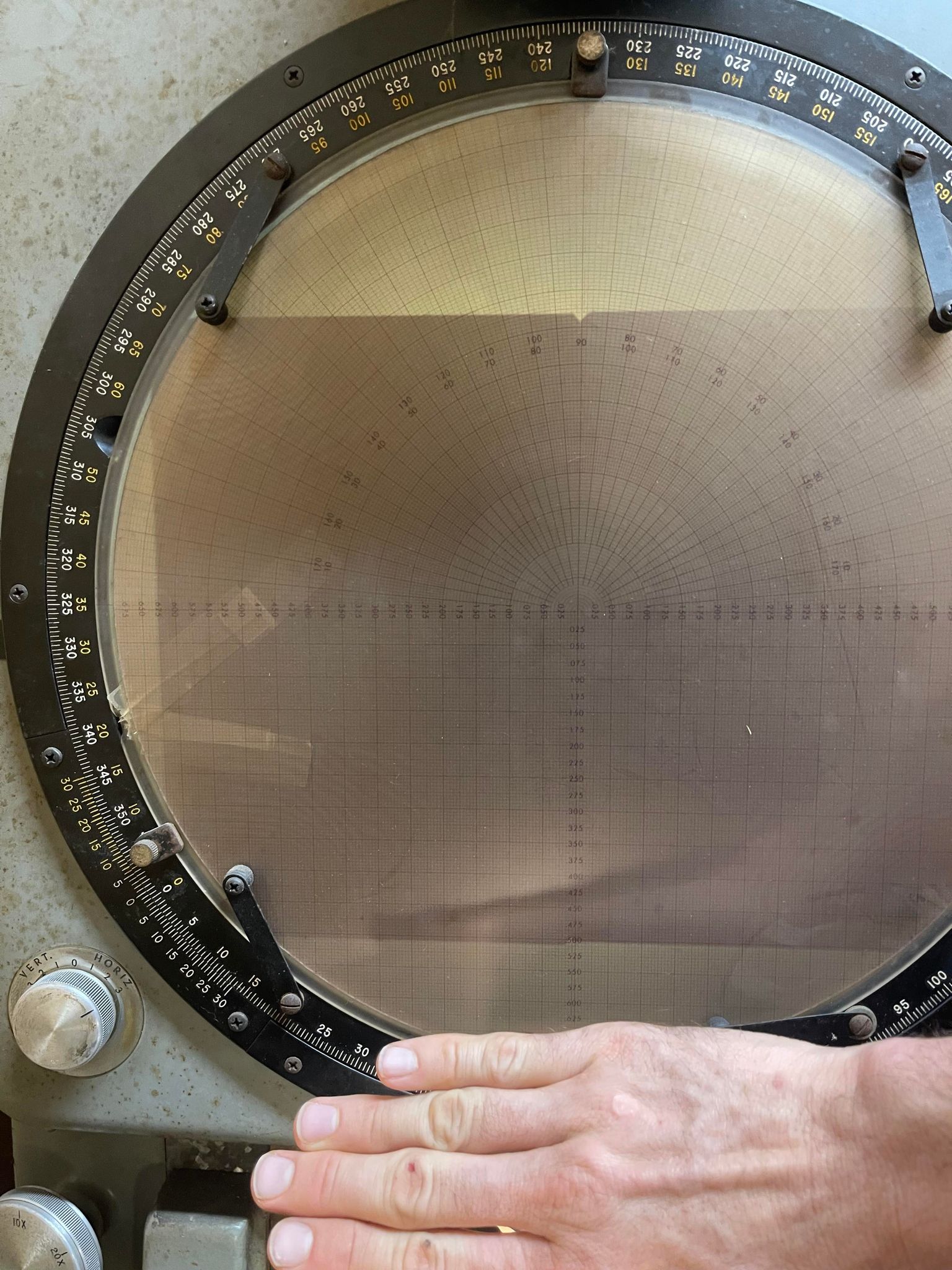

Testing on Bench : I first put the barrel on the optical comparator to show the shoulder on the shadowgraph in 20x zoom, it lines up true on the comparator grid. There's a different in the chamfer from one side to the other on the barrel. This is not due to eccentricity in the threads or shoulder WRT to the bore. Instead it's because the OD of the contour had a lousy relationship to the ID of the bore. My program cuts a chamfer all in one setup and sometimes if the OD/ID is poor then the chamfer looks out of whack. Additionally the muzzle cap is a shelf item, we make them in large batches of different OD's and screw them onto the barrel when it's done. Someone previously opined that it was likely made at the same time so it would have a clean fit. That's not the case, they're not created at the same time. If the shoulder was crooked the thread cap would show a gap between the shoulder and the cap just like if there was a gap between the TBAC mount and the shoulder in the picture posted originally. There is no light gap there. It's pretty darn hard to get a barrel 26" long onto a 12" wide comparator table but we got pretty close.

See the photo below:

Testing in the spindle.

I ran the same test of mounts and adapters in 4 different ways to rule out potential problems.

Combo 1: bar stock drop from the scrap bin, threaded 5/8-24

Combo 2: Existing barrel, dialed in on the bore to within 0.0002

Combo 3: Set the shoulder back 0.005"

Combo 4: Set the barrel thread back and cut completely new threads onto the barrel.

We also put the barrel into the contouring lathe and skimmed out the OD/ID relationship to be much closer since I was bugged by it being off (it wasn't our contour, customer supplied blank).

Mount A: TBAC CB mount from our stock, new and unfired.

Mount B: 419 system consisting of a universal adapter and the suppressor mount.

The 419 base adapter that screws onto the muzzle was confirmed on the barrel and the test stub to be free of runout. This is the piece that the TBAC adapter mounts onto it.

Test 1: Check each shoulder for runout

Test 2: Snug TBAC CB mount into place and check runout on the taper.

Test 3: Snug Area419 adapter (the part that touches the barrel) into place and check runout on shoulder and taper

Test 4: Snug Area419 mount (the part that touches the suppressor) into place and check runout on the taper where it contacts the suppressor.

So there's a bunch of fiddling and testing that went on, it took about 90 minutes to get through all the stuff and take short video clips. Unfortunately I don't know how to pause a video on an iPhone and string together a stack of clips.

The material slug is there as a reference standard for all other tests. If the test and indicators are repeatable then the runout from each iteration should be the same between the barrel and the slug if the barrel isn't the problem.

Theoretically if there is absolutely no runout in the machine and the test parts then there should be no runout discernible under testing the material slug with all combos of the mounts.

TBAC mount on the Combo 1: material slug ~0.001"

TBAC mount on Combo 2: "as returned" barrel ~0.001-0.0012"

TBAC mount on Combo 3: barrel with 0.005" skim shoulder ~0.001

TBAC mount on Combo 4: freshly setback barrel ~0.001"

Conclusion here: TBAC mount showed about 1 thou of runout through all tests, the only change being the Combo 2 test which was slightly more. This is the test where dialing in the barrel again could easily have created the slight increase in runout detected.

419 universal adapter: no appreciable runout detected on any of the test combo's. No further discussion needed.

Next 419 TBAC mount system assembly. The used mount had a discernable contact ring on the taper from the suppressor contacting it during use. This contact ring shows to be inconsistent around the circumference indicating inconsistent contact on the taper.

We used the contact mark on the taper to indicate from since this is clearly where the customer's suppressor was touching the mount.

Combo 1: 0.004-0.0045"

Combo 2: ~0.005"

Combo 3: ~0.0045-0.005"

Combo 4: ~0.0045" (Video Below)

Projecting that runout over the length of a 9" long suppressor would result in the videos that @Westbound created, excessive TIR at the endcap aperture.

The test was repeated for the second 419 mount that was supplied by the customer in the box.

Combo 1: 0.0055"

Since this component was unused by the customer and it showed the same level of TIR on Combo 1 testing I stopped at that point. We had localized the culprit and I needed to get back to other work.

I have not had a chance to upload the all videos because they're on my phone,.They look like the ones from Randy except they're in a different lathe. This is the last video after having tested all the various combinations. This is Area419 with the universal adapter and the TBAC mount on a freshly cut muzzle.

Everything is going back to @GBMaryland tomorrow.

There was a pair of clues for troubleshooting & throwing blame around early on, so an educating time for those on the thread: The runout behavior was seen on a different barrel from a different company. Chances of that happening and it being 2 screwed up barrels and not a screwed up mount are very low. Second clue: the barrel was stated to shoot 1 hole without the adapter kit installed, if the crown was so screwed up that threads were causing baffle strikes the issue would very likely cause accuracy problems as well.

One note: @GBMaryland the front action screw on your chassis is impinging on the barrel tenon, the screw is about 1 thread too long. See below, there's a nasty ding in the corner of the barrel tenon where the action screw is driving into it.

Testing on Bench : I first put the barrel on the optical comparator to show the shoulder on the shadowgraph in 20x zoom, it lines up true on the comparator grid. There's a different in the chamfer from one side to the other on the barrel. This is not due to eccentricity in the threads or shoulder WRT to the bore. Instead it's because the OD of the contour had a lousy relationship to the ID of the bore. My program cuts a chamfer all in one setup and sometimes if the OD/ID is poor then the chamfer looks out of whack. Additionally the muzzle cap is a shelf item, we make them in large batches of different OD's and screw them onto the barrel when it's done. Someone previously opined that it was likely made at the same time so it would have a clean fit. That's not the case, they're not created at the same time. If the shoulder was crooked the thread cap would show a gap between the shoulder and the cap just like if there was a gap between the TBAC mount and the shoulder in the picture posted originally. There is no light gap there. It's pretty darn hard to get a barrel 26" long onto a 12" wide comparator table but we got pretty close.

See the photo below:

Testing in the spindle.

I ran the same test of mounts and adapters in 4 different ways to rule out potential problems.

Combo 1: bar stock drop from the scrap bin, threaded 5/8-24

Combo 2: Existing barrel, dialed in on the bore to within 0.0002

Combo 3: Set the shoulder back 0.005"

Combo 4: Set the barrel thread back and cut completely new threads onto the barrel.

We also put the barrel into the contouring lathe and skimmed out the OD/ID relationship to be much closer since I was bugged by it being off (it wasn't our contour, customer supplied blank).

Mount A: TBAC CB mount from our stock, new and unfired.

Mount B: 419 system consisting of a universal adapter and the suppressor mount.

The 419 base adapter that screws onto the muzzle was confirmed on the barrel and the test stub to be free of runout. This is the piece that the TBAC adapter mounts onto it.

Test 1: Check each shoulder for runout

Test 2: Snug TBAC CB mount into place and check runout on the taper.

Test 3: Snug Area419 adapter (the part that touches the barrel) into place and check runout on shoulder and taper

Test 4: Snug Area419 mount (the part that touches the suppressor) into place and check runout on the taper where it contacts the suppressor.

So there's a bunch of fiddling and testing that went on, it took about 90 minutes to get through all the stuff and take short video clips. Unfortunately I don't know how to pause a video on an iPhone and string together a stack of clips.

The material slug is there as a reference standard for all other tests. If the test and indicators are repeatable then the runout from each iteration should be the same between the barrel and the slug if the barrel isn't the problem.

Theoretically if there is absolutely no runout in the machine and the test parts then there should be no runout discernible under testing the material slug with all combos of the mounts.

TBAC mount on the Combo 1: material slug ~0.001"

TBAC mount on Combo 2: "as returned" barrel ~0.001-0.0012"

TBAC mount on Combo 3: barrel with 0.005" skim shoulder ~0.001

TBAC mount on Combo 4: freshly setback barrel ~0.001"

Conclusion here: TBAC mount showed about 1 thou of runout through all tests, the only change being the Combo 2 test which was slightly more. This is the test where dialing in the barrel again could easily have created the slight increase in runout detected.

419 universal adapter: no appreciable runout detected on any of the test combo's. No further discussion needed.

Next 419 TBAC mount system assembly. The used mount had a discernable contact ring on the taper from the suppressor contacting it during use. This contact ring shows to be inconsistent around the circumference indicating inconsistent contact on the taper.

We used the contact mark on the taper to indicate from since this is clearly where the customer's suppressor was touching the mount.

Combo 1: 0.004-0.0045"

Combo 2: ~0.005"

Combo 3: ~0.0045-0.005"

Combo 4: ~0.0045" (Video Below)

Projecting that runout over the length of a 9" long suppressor would result in the videos that @Westbound created, excessive TIR at the endcap aperture.

The test was repeated for the second 419 mount that was supplied by the customer in the box.

Combo 1: 0.0055"

Since this component was unused by the customer and it showed the same level of TIR on Combo 1 testing I stopped at that point. We had localized the culprit and I needed to get back to other work.

I have not had a chance to upload the all videos because they're on my phone,.They look like the ones from Randy except they're in a different lathe. This is the last video after having tested all the various combinations. This is Area419 with the universal adapter and the TBAC mount on a freshly cut muzzle.

Everything is going back to @GBMaryland tomorrow.

So the TLDR bad batch of Area419 CB mount huh. Well, hopefully they can get that 'straightened' out.

Last edited:

I can’t thank you enough for doing all of that… And I really appreciate you figuring out where the problem was.

So, as stated by Josh:

- the Area 419 5/8x24 barrel adapter is fine

- the Area 419 suppressor CB mount has considerable run out

- the barrel was fine, but he cleaned it up anyway

- the TBAC OEM CB brake / mount has a small run out

This is consistent with what we saw on the two separate barrels using the witness rod.

The issue is we couldn’t really tell what part was causing the problem and thanks to PVA we now have comprehensive information.

At this point I guess I have to call area 419 and figure out what we’re gonna do about the CB mount adapter.

I want to thank Josh and the folks at PVA for doing such an above and beyond amount of work to check this for me! In reality the problem was not theirs but another vendor’s.

Every vendor has been pretty upstanding and very helpful… And I really do appreciate all of their time.

So, as stated by Josh:

- the Area 419 5/8x24 barrel adapter is fine

- the Area 419 suppressor CB mount has considerable run out

- the barrel was fine, but he cleaned it up anyway

- the TBAC OEM CB brake / mount has a small run out

This is consistent with what we saw on the two separate barrels using the witness rod.

The issue is we couldn’t really tell what part was causing the problem and thanks to PVA we now have comprehensive information.

At this point I guess I have to call area 419 and figure out what we’re gonna do about the CB mount adapter.

I want to thank Josh and the folks at PVA for doing such an above and beyond amount of work to check this for me! In reality the problem was not theirs but another vendor’s.

Every vendor has been pretty upstanding and very helpful… And I really do appreciate all of their time.

At this point I guess I have to call area 419 and figure out what we’re gonna do about the CB mount adapter.

Please update when you get an answer from them. I think I am going to buy some rods to check my alignment. Thanks to @bohem from me as well. It's nice to get a solution.

Awesome info! I have a A419 CB adapter sitting in the safe while I’m waiting for my Ultra 9 stamp. I’ll be checking it with an alignment rod for sure.

It's not just the crown... It's probably the threads, as well. I'd just make them buy you a new barrel and refund labor, and have another smith install the new one. Obviously, PVA's machinists suck, and it seems their CS is terrible, too, if you can't get in touch with them. Regardless, just on those 2 strikes alone, I'd be finding me a new smith.

Think we’re gonna see @FuhQ return to this thread and apologize or is he too busy in his Arken threads??

To the OP-Glad to see the issue appears well on its way to being resolved.

Think we’re gonna see @FuhQ return to this thread and apologize or is he too busy in his Arken threads??

To the OP-Glad to see the issue appears well on its way to being resolved.

new to this thread and not sure if this is relevant at all but I had a helllfire suppressor mount for my TBAC Dominus cb and it simply didn’t thread into the suppressor. I was so confused. (I posted a question about it elsewhere on the ‘hide about it.). I sent an email with pictures to area 419 and they just sent me another mount that threaded perfectly (and the rifle shoots like a charm) It was kind weird since the never actually responded they just sent the new mount. In any event I wondered if they had a bad batch of mounts somehow.

The biggest appeal, especially with me, is being able to compete in states that restrict suppressor use.I've never understood the appeal of Area419 adapters. For the record, I think Area419 is a great company and I'm really happy for Jon's success. I have no axe to grind. But as far as the adapter system it just seems like a solution to a nonproblem. The only logical justification would be for someone who wants to regularly swap between a brake and a suppressor. But why would someone do that? Either use TBACs CBA's or just direct thread your suppressor and self-timing brakes on. Seems like such an unnecessary intermediary. Like real estate agents.

I personally have not seen any issues between my numerous TBACs, Dead Air, etc. suppressors. I run the area419 system in 100% of them and play switcheroo depending on the weather, what I drank the night before, or how the earth is rotating that day....

The appeal for me is to be able to use any suppressor on any rifle.

Provided the mounts are the correct tolerance, it’s a great concept.

Provided the mounts are the correct tolerance, it’s a great concept.

Multiple suppressors that use multiple mounts.I've never understood the appeal of Area419 adapters. For the record, I think Area419 is a great company and I'm really happy for Jon's success. I have no axe to grind. But as far as the adapter system it just seems like a solution to a nonproblem. The only logical justification would be for someone who wants to regularly swap between a brake and a suppressor. But why would someone do that? Either use TBACs CBA's or just direct thread your suppressor and self-timing brakes on. Seems like such an unnecessary intermediary. Like real estate agents.

Now they all the same.

I'm constantly checking my direct thread suppressors to make sure they are tight because they always loosen.

Also I have barrels threaded 1/2x28, 5/8x24, and 3/4x24. So I'll need something anyway

Also I have barrels threaded 1/2x28, 5/8x24, and 3/4x24. So I'll need something anyway

Not all barrels have the same threads. I have 3/4 and 5/8 barrels I use my 338ba on.That's what I don't get. Direct thread is the OG of universal mounting systems and is already paid for in the barrel install. Why use a female USB to adapt a male USB to another female USB for your male USB power cord?

I switched from the ba mounts to the sidewinder setup because I was tired of carbon scraping off the brake and into the threads of the can. No matter how much I cleaned it would always get in there and the thread tolerance seems to be very tight. I had to witness mark my can and mounts to make sure it was actually seated. A few specs of carbon would give false positives.

I have the same problem with all the barrels having different threads.

Yes I do swap them from time to time.

This makes that whole issue much less of an issue.

In my case I have some weapons with metric threads in some weapons with standard threats and this fixes most of that problem

Yes I do swap them from time to time.

This makes that whole issue much less of an issue.

In my case I have some weapons with metric threads in some weapons with standard threats and this fixes most of that problem

So you bought a thread adapter for your barrel. Screwed on a qd that was fixed into your suppressor.

OP bought a universal adapter for his barrel. Screwed on an adapter that was fixed into his suppressor.

But yes, yours is completely different.

OP bought a universal adapter for his barrel. Screwed on an adapter that was fixed into his suppressor.

But yes, yours is completely different.

So you still stacked another piece in there…. The main thing for me was the carbon issue. Being able to use one of 419’s brakes was an added bonus.Okay. That's one example. And I have one .223 barrel that I use my direct thread 5/8 24 Ultra 5 on. So I bought one 1/2 28 to 5 8 24 thread adapter. Doesn't require a family of barrel adapter's so every can could be used on every barrel. I'm sure 5/8/24 to 3/4 thread adapters are a thing.

Honestly. I think people in this sport look for little gadgety things to spend their money on and there's a lot of allure in that for this product. And the drawback of that is the last two pages of this thread

It was an even swap to go from the used asr systems to the new 419 for me so I wouldnt say Im out anymore cash than with any other can mount.

For me, since I dont shoot with a break and only with a can, I could go with the direct thread cans and put a thread adaptor on the differently threaded barrels to make them all a standard 5/8 thread and it would be cheaper. BUT I just feel the 419 system is a more elegant version of the same thing and so 40 bucks for a barrel adaptor isnt a big deal so its what I run and it makes every cans interface fit on the end of every barrel I have with no worrying about anything.

I struggle to articulate why I dont like normal direct thread, it just seems like I have a higher chance of buggering up barrel threads than the adaptors threads so 419 seems like a safer choice I guess? I can throw a can down on the uni adaptor and it self centers itself via the oring on the cone and then it just screws straight on, I dont have to worry about getting anything straight to start etc. like with direct thread.

Edit: well safer so long as its cut even lolz

For me, since I dont shoot with a break and only with a can, I could go with the direct thread cans and put a thread adaptor on the differently threaded barrels to make them all a standard 5/8 thread and it would be cheaper. BUT I just feel the 419 system is a more elegant version of the same thing and so 40 bucks for a barrel adaptor isnt a big deal so its what I run and it makes every cans interface fit on the end of every barrel I have with no worrying about anything.

I struggle to articulate why I dont like normal direct thread, it just seems like I have a higher chance of buggering up barrel threads than the adaptors threads so 419 seems like a safer choice I guess? I can throw a can down on the uni adaptor and it self centers itself via the oring on the cone and then it just screws straight on, I dont have to worry about getting anything straight to start etc. like with direct thread.

Edit: well safer so long as its cut even lolz

Last edited:

You don't have to regularly check whether the can has loosened on the direct thread.I struggle to articulate why I dont like normal direct thread...

And for everyone else let's be honest even if you DID have 10 threaded rifles the cost for the Area419 system ends up being about the same for 10 CB/ASR/Dead Air combo brakes. It doesn't cost $2500 at $40 each ($40x10=$400) plus can adapters. Not sure where that came from.

You don't have to regularly check whether the can has loosened on the direct thread.

And for everyone else let's be honest even if you DID have 10 threaded rifles the cost for the Area419 system ends up being about the same for 10 CB/ASR/Dead Air combo brakes. It doesn't cost $2500 at $40 each ($40x10=$400) plus can adapters. Not sure where that came from.

When is the last time you priced a CB brake? There's a reason used don't last long in the PX here for $90 shipped.

Maybe im missing something. Asr/da brakes are $100 depending in where you buy them, CB brakes are $135 ish. So outfitting 10 rifles would be 2-3 times more expensive than 419 universal adapters roughly. Now if you have 10 cans with 10 suppressor adapters for those 10 rifles, then the cost is basically equal. Id say nobody does that though.You don't have to regularly check whether the can has loosened on the direct thread.

And for everyone else let's be honest even if you DID have 10 threaded rifles the cost for the Area419 system ends up being about the same for 10 CB/ASR/Dead Air combo brakes. It doesn't cost $2500 at $40 each ($40x10=$400) plus can adapters. Not sure where that came from.

As an update:

I've reached to Area 419 both on the hide via PM and I've called and left them a message.

I have yet to hear anything back, so we'll see what they have to say.

I have a SERIOUS amount of money in their adapters, as I plan to use them on all of my cans. So, if I don't hear back from them, I'll be needing to get a refund for all of that stuff. (Which would blow... I really just want a 419 CB Mount that doesn't have run out...)

Waiting to hear back...

I've reached to Area 419 both on the hide via PM and I've called and left them a message.

I have yet to hear anything back, so we'll see what they have to say.

I have a SERIOUS amount of money in their adapters, as I plan to use them on all of my cans. So, if I don't hear back from them, I'll be needing to get a refund for all of that stuff. (Which would blow... I really just want a 419 CB Mount that doesn't have run out...)

Waiting to hear back...

It was an even swap to go from the used asr systems to the new 419 for me so I wouldnt say Im out anymore cash than with any other can mount.

For me, since I dont shoot with a break and only with a can, I could go with the direct thread cans and put a thread adaptor on the differently threaded barrels to make them all a standard 5/8 thread and it would be cheaper. BUT I just feel the 419 system is a more elegant version of the same thing and so 40 bucks for a barrel adaptor isnt a big deal so its what I run and it makes every cans interface fit on the end of every barrel I have with no worrying about anything.

I struggle to articulate why I dont like normal direct thread, it just seems like I have a higher chance of buggering up barrel threads than the adaptors threads so 419 seems like a safer choice I guess? I can throw a can down on the uni adaptor and it self centers itself via the oring on the cone and then it just screws straight on, I dont have to worry about getting anything straight to start etc. like with direct thread.

Edit: well safer so long as its cut even lolz

I can see the point about potentially protecting the barrels threads, and yes, the A419 system allows you to share suppressors across a variety of platform hosts (as does TBAC, ASR, Keymo, Plan B, etc.).

Direct thread is certainly more elegant of a solution than adapters, especially ones such as the A419 that adds little increased functionality while increasing potential issues due to tolerance stacking.

I think some of the taper mounts mitigate the potential for such errors as observed in this thread and others, though they aren't immune from issues themselves either.

No free lunch either way. Some of my rifles are direct thread, some have Rearden MFG mounts (Q Plan B pattern). They all have their own nuances. There's no perfect system, but there are systems more optimal than others for certain uses.

Oddly enough when I ran direct thread that’s the only time I had issues with cans coming loose across a few different rifles.You don't have to regularly check whether the can has loosened on the direct thread.

And for everyone else let's be honest even if you DID have 10 threaded rifles the cost for the Area419 system ends up being about the same for 10 CB/ASR/Dead Air combo brakes. It doesn't cost $2500 at $40 each ($40x10=$400) plus can adapters. Not sure where that came from.

Similar threads

Gunsmithing

Omega 300 end cap brake adapter

- Replies

- 13

- Views

- 629

- Replies

- 2

- Views

- 202

- Replies

- 5

- Views

- 341

- Replies

- 0

- Views

- 299