Re: stainless barrel in cold weather...

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: bohem</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: SpotcheckBilly</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: bohem</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: SpotcheckBilly</div><div class="ubbcode-body">There are facts and then there are ancedotes.

For example -

Fact: 416R stainless steel is more brittle than 4140 or 4150 CM steel and will be much more prone to fail in a lightweight barrel firing a very high pressure cartridge at ambient temperatures that are far below zero degrees F.

Anecdote: "My hunting buddies and I have been using stainless sporter weight rifles in magnum chamberings for years and never experienced any problems with the barrels bursting in sub zero temperatures."

Both are true. The choice is yours. </div></div>

From the experience I have with high strength stainless alloys in various environmental conditions, all under intense load conditions, your first stated "fact" isn't applicable whatsoever.

Some of the toughest, highest elongation to failure (ie, NOT brittle) steels you can get ahold of are stainless. Properly manufactured, they're also some of the strongest and hardest materials.

Hardness and tough are two general qualities that don't go together.

I see no reason to worry about this. Yet again back to claims by manufacturers on something that might not normally be questioned. See the thread going about surgeon actions eliminating muzzle flip.</div></div>

You might learn the difference between facts, anecdotes and opinions. You've shared your opinion, now let's get to some facts.

There are approximately 150 variuos types of stainless steel.

I cited 416R barrel steel specifically. I make no references to other "high strength stainless alloys" as you do, because they're not really applicable to the op's question that started this thread.

Just what experience do you have with stainless steel to lead anyone to believe what you've posted? I'm not claiming any real expertise on this matter, but I know how to research it, and have questioned a couple of ME's about this subject.

You act as if you know what you're talking about, but you've got a whole lot to learn. Instead of handing it to you on a platter, why not do your own research?I'llstart you off with these hints -

Read about the need to add sulphur to the 416 alloy and its negative effects.

Then find out why 416 alloy must be tempered between 700F and 1100F and what the term "temperature embrittlement" means.

Research what happens to a stainless alloy (416) when it winds up with a microstructure containing "sulphide stringers" and has been tempered in a bad tempering environment.

Investigate what the effect of very low ambient temperatures has on an alloy with these properties.

Do that, then maybe you'll have a clue as to why some rifle barrel makers either hesitate or refuse to use 416 stainless in their lightweight barrels.

Or don't

For the rest of you Hide members you might find this link enlightening -

http://yarchive.net/gun/barrel/barrel_steel.html

Scroll down towards the bottom of the thread to find Bart Bobbitt's take on the subject. </div></div>

My Masters in Mechanical Engineering is focused on the research and analysis of micro-cracking in materials at an atomic level based on the chemical bond states of those materials. I have 2 degrees in Mechanical Enigneering.

My reference to "high strength alloys" is because the very specific family I'm talking about is proprietary to the aerospace company I work for as a Stress Engineer. Cold weather considerations are a direct inclusion in our testing because, as I'm sure you know, the atmosphere gets a little chilly when you get to 30,000 ft. Doesn't matter where you are over the earth.

The sulfur content you're talking about is one of the contributing factors to the "unzipping" effect that happened in the carbon steel in the Titanic's hull plates as the water temp chilled it to appx. 30F and the became extremely brittle. It exists in a number of metals, my roommate in grad school did his PhD thesis on analytic solutions that deal with those inclusions. Our masters degrees are identical. His was focused on a specific family of alloys, mine was focused on a generic analytical solution to the fracture attributed to the composition issues.

Since you admit you don't know what you're talking about, yet you seem to think it reasonable to accuse me of being out to lunch, let's discuss the comments on that link you provided.

So here's my take on Mr. Bobbitt's comments about cold weather fatigue strength of 416R (none of which actually bring up any numbers, they're simply statements).

What cycle count is he talking about that based his opinions on the fatigue strength reduction to be dangerous?

What stress level is he operating at?

What test data has he been privy to that showed a burst hazard? Has this been demonstrated in a lab somewhere or is it just an opinion that comes down from someone having only enough understanding to "be dangerous"?

Why are only the heavy magnums a problem in light barrel contours? Does a 300 WM operate at pressures so much higher than a 22-250? Let's take a look at published pressure values to actually show some numbers for comparison.

300 WM max pressure I can find published? 62,600 psi

22-250 max - 62,900 psi

That's a 0.5% difference in operating pressure.

What about a hot 30-06 load, which is the same bore diameter.

61,700 psi.

I'd go out on the uneducated limb and say that 900 psi wasn't making the difference.

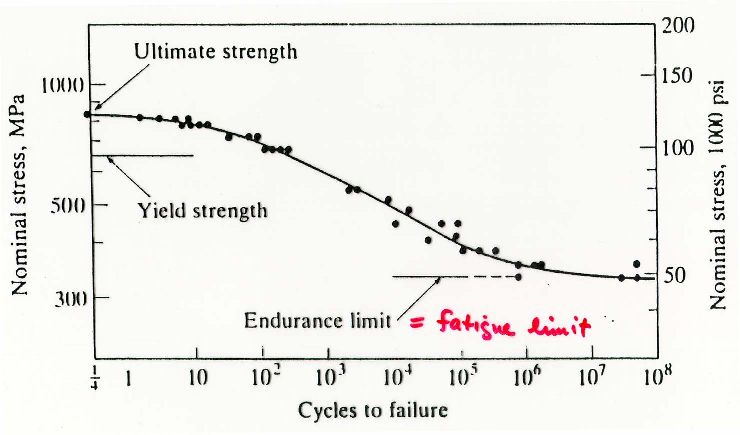

Rifle barrels are not a high fatigue count item. They are an extremely low fatigue count item. How many rounds does a 300 WM barrel last for? 6000 rounds at the outside? Let's call it 10,000 just to be argumentative. Fatigue lives are calculated in tens of millions of cycles. The SN diagrams for that particular alloy (416R Harndess 22-25Rc) in tension/shear loading (and remember that hoop stress from a pressure load is a tension/shear load in the material) in our material database at work stops at 100,000 cycles. Even at 10X's the barrel life you might possibly ever achieve, this steel maintains triple it's infinite endurance limit at -60*F.

Your article that you posted is a 13 year old email train that does nothing more than discuss possibilities. Mr. Bobbit doesn't make a single, actual mention of the stress levels that he's talking about, just etherial mentions that it could be dangerous.

Substantiate his claim with actual numbers and we'll discuss it. Until then, methinks you need to do some more research rather than copy and paste old off the cuff discussions that have no more substantiation in them than taking an engineering textbook and copying a sentence out of it wihtout a quote.

I've seen the tests, I've worked with the test data, I make sure the materials selection for the stress levels involved keep flight safe. I'm working on stress analysis now that deals with the thermal effects of mating composites, specifically graphite fiber composite, to AL, TI and CRES structures in aircraft that see temperature swings from -65 to +135F. I might know just a little bit about it.</div></div>

So I'm guessing SS is good to go in cold weather? From a mechanical engineering point of view?