Re: Stainless Steel Media Testimonials

Just FYI concerning the Thumlers.

Be sure to remove the rubber lining periodically and dry out the steel.

Its not painted inside and will rust if water gets between the liner and the steel.

Here is my draining method:

I gently dump the water from the tumbler into the sink.

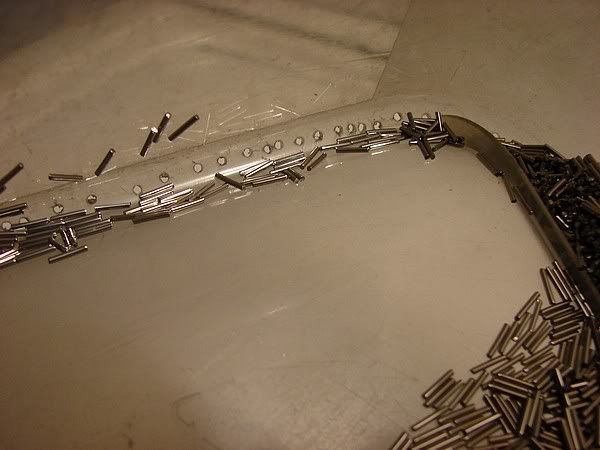

Then just turn the thing over into the large strainer and shake away.

Then I stick the thing under the sink and run water thru the cases into the tub, again shaking further.

For me the media is always inside the cases (as well as outside) and I take three at a time and 'drain' out the pins. A bit tedious.

As the cases get emptied I drop them into a plastic Folgers container.

Eventually all the cases are out and I shake the large strainer to get all the pns to fall thru.

I then empty the tub of water and 'pour' the pins into the small round strainer which has a much tighter weave and start rinsing the pins out.

It takes me about three batches to empty the big tub.

I just dump the pins into the rubber of the Thumlers.

I then size the cases and the Lee neck sizing rod takes care of any pins that get stuck lenghtwise in a .223 case. Pretty obvious when it happens and I just shake that pin out of the case.

I drop these lubed cases back into the Folgers tub which has a solution of water/dish soap/lemishine again (very little) as this is the quickest method I found for removing the Lee lube.