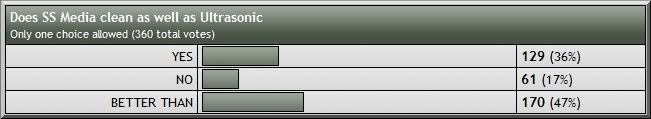

Re: Stainless Steel Media Testimonials

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: kombayotch</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: recce556</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Chiller</div><div class="ubbcode-body">really want to know these 54 people..... </div></div>

As the saying goes, "Haters gonna hate"...these 54 people obviously have NOT tried it and just voted. There is NO POSSIBLE WAY that other methods listed gives you BETTER results (I have tried all three methods myself). The ONLY way they could have gotten worse results is if they somehow screwed up (tip: don't add a tin of black shoe shine to your tumbler!) </div></div>

That assumption would be incorrect. I was doing this with angle cut ceramic media, ceramic beads and used primers long before anyone started selling this stuff and was one of the first people to buy it when it did showed up. I posted severalthreads about it. Does it get the cases cleaner and shinier than other methods? Sure.

However, when I consider the overall time spend removing the burr left by that peeing and headaches it causes in a tighter match chambers, it simply isn't worth it. The little bit of extra clean isn't worth the hassle caused by the peeing. Yes, that burr can be removed by trimming shorter, but that only works once unless you want to keep hacking down your brass. Every time you clean with this media, the cases get shorter on their own. Its actually nice if you have a chamber that is loose enough to tolerate the burr because you never have to trim your brass. Great in my Lee Enfield, but in my precision guns those burrs cause fits and have been a PITA to remove. I can see the effects of them not only in velocities and on paper, but in the pressure traces I take with my RSI system. Every time I get a little spike in velocity or pressure, if I take the fired case and try to drop a bullet into it, I can feel the friction of the remaining burr still grasping the bullet. This causes HUGE variations in neck tension. It's basically a donut at the case mouth. It prevents a clean release of the bullet and chamferring doesn't always get it all.

Sure the US system doesn't polish the scratches out of the cases, but I can polish them in the regular tumbler every few firings if I want to and then clean the dust out in the US. That new Hornady solution is amazing. It only takes 15 min to get the cases completely clean using it in the US (Branson 2510), even less if I clean the primer pockets quickly with a uniforming tool (which takes far less time than removing the burr). For pistol brass, I've just been putting it in the tumbler with the Hornady solution, but without the SS media. Gets just as clean on the outside and nearly as clean and polished on the inside without the hassle of having to separate the media out. Doesn't need to be shiny clean on the inside for pistol rounds. I don't bother deprimming the cases either, it also isn't necessary for pistol rounds.

The only thing I use this stuff for anymore is polishing bullet that I've swaged. Never use it for cases anymore, and believe me, it isn't because of lack of experience using it. If this stuff works with your chamber, then great! But don't assume that it's all unicorns and rainbows with every gun out there because it isn't. </div></div>

I had an unpleasant experience with the SS method about a month ago. The same thing you mentioned with the peening of the lips on the mouth of the brass.

I have a tight neck chamber,and fitted dies. Although I had used the SS method before with this brass I had always trimmed out of habit. But on this particular 50 reloads I didn't bother to trim. I noticed that the seating tension was much more than usual. I thought no biggy it won't hurt accuracy much. Wrong!! The groups were poor compared to normal and vertical at distance was 3 times more than what was typical. It seemed like the pressures were higher creating more velocity too,because I was hitting a little higher.

For pistol I think the SS method works excellent. I shoot lead bullets mostly and bell the brass anyways so I don't care if the lips are dinged up. Then by the time I crimp,the cases are pretty much back to normal. I don't plan on shooting the Bianchi cup or any precision pistol events so I'm happy as is.

Previously before I tried the SS method I used a Ultra sonic(US). My US has never worked the greatest. I had to US the cases for hours not minutes. They weren't shiny and I didn't want to get corncob media dust on them so I didn't use the vibratory cleaner to shine them up then have to rinse them again.

Today I decided to experiment with both the US and the SS method combined. I filled a large beaker with the cases primer pockets up and use a teaspoon of citranox. Then run it for a 1/2 hour in the US. It gets the cases about 70% clean and loosens up the carbon. I get another batch going in the US while I load up the Thumblers Tumbler with the brass I just US'd. I use all 5 lbs SS,put the Dawn and Lemishine in and fill the water almost to the top. Run this for 35-40 minutes. The cases come out clean and shiny as if I ran the TT for 4 hours except the lips of the brass are barely dinged. I can drag my finger nail across the lips inside and out and can't feel a edge like I used to when running the TT for 4 hours. The cases lengths measure the same as when I put them into the TT. I think the extra water and short run time is easier on the lips of the brass and this combined method goes faster,almost too fast actually.

I'll let you guys know how they shoot trimmed and untrimmed in a week or two.