Just finished building my NFA registered SBR Sterling SMG converted to semi-auto only. This proved to be a far bigger pain in the ass than I anticipated. A lot of the components; stock, stock butt cap, butt cap mounting sleeve, sights, trigger assembly, front trunion, and handguards were silver soldered/brazed in place using a very high heat solder. I had to grind most of them off. The bolt diameter didn't match my tube diameter and the front trunion was too small in diameter. I ended up making a sort of a Sten/Sterling hybrid. The good news is it runs really well. I ended up using a Sten magazine group, barrel trunion and barrel. Then I screwed and welded everything together. I fabricated a new front trunion for the barrel and handguard. The front heat shield and rear tube are two separate pieces joined by the Sten mag well. The gun uses Sten magazines. I impressed myself with my soldering skills when I succeeded in attaching the semi-circular handguards to the front of the ejection port and muzzle end of the handguard. The original Sterling had a textured finish and I was able to duplicate this quite nicely with a Krlyon textured spray paint. I was going to spray a matte clear cerakote over the paint but the paint looks pretty good as is and seems to wear well.

I'm a soldering machine.

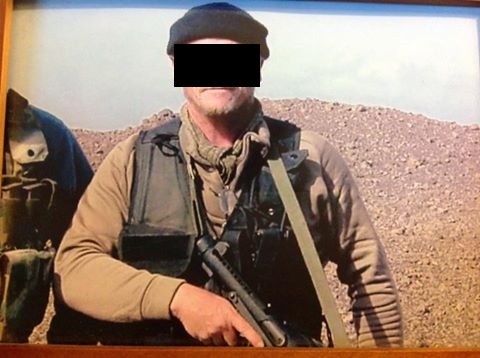

Fellow 10th grouper with a Sterling he carried as a Private Military Contractor.

I'm a soldering machine.

Fellow 10th grouper with a Sterling he carried as a Private Military Contractor.

Last edited: