Build... assembled... I don’t care what you call it, I put it together myself from parts and it puts a smile on me face, mate LOL

Earlier this year I came across a deal I could not pass up while window shopping on midway. They were selling off their inventory of AAC 260 barrels at half off. These barrels are pre threaded on both ends and chambered. The idea is to allow DIY’ers the ability to swap barrels on their Remington actions provided you have the proper tools. I place an order for a couple 260’s and a 308. This thread is about my time with the 260.

At first I thought I’d use one of my Remington’s that doesn’t get much use, a 26” 308 varmint. After searching this wonderful site for tips on how people have been taking off their factory barrels and gaining a little knowledge of the process (I will detail this in a later thread on the 18” 308 AAC barrel). I found the task straight forward and made the swap. However, after some productive range time that showed the barrel to shoot well I started thinking... dangerous I know... I decided it was time for my first custom action that shared the same Remington set up and headspacing.

I decided it was time for my first custom action that shared the same Remington set up and headspacing.

I contacted Bugholes here on the hide and placed an order for one Stiller Tac30 A/W action. After just a few days I had my action...

I am happy to say it was a quick and easy swap and with the Stiller action and recoil lug everything fit nicely. I dropped in my go gauge and the bolt closed, dropped in my no go gauge and the bolt closed with heavy resistance, dropped in the field gauge and it would not even come close to closing... Just about perfect and tighter headspace than my three factory Remington rifles in the safe.

At first I attached the barreled action into a AICS stock and checked to see if my new action would feed from AW mags and I am happy to say it did.

first rounds on target

with a AAC 308 brake

Some dont care for the barrel profile but its grows on you and balances well

Then I tried AICS mags and found that the bolt was coming into heavy contact with the feed lips. So keep this in mind if you decided to take up a similar self build idea. If you use a AW action you may have to stick with AW mags. That said I have now swaped the barreled action into a Manners T4 and at this point it is feeding reliably with both unless you press into a barricade and/or hold pressure against the front of an AW mag. So there may be a happy medium where both mags will work or maybe not... I have not played around with making adjustments to the mag release that dictates the height of the mag when seated. That will have to wait till after deer season.

The barrel was giving me fits finding a load that would shoot well. Part of my problem was I have another 260 and assumed that a good accuracy node would/should work in both rifles... well it both does and doesn’t, it just depends on what you are after. The load I having been using in my other 260 (44g of H4350 w/140 class bullets) was way too hot to use in this barrel. Initially I found 43g of H4350 to work but it would shoot well one day and not the so well the next accuracy wise. My vertical was averaging .6 moa and then the next time out it would be near moa or larger at distances of 100-700 yards.

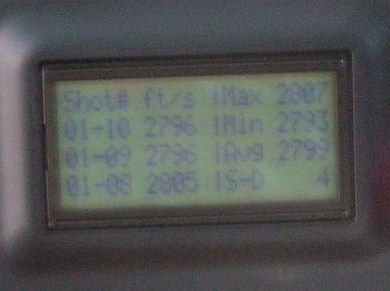

One thing I have noticed is with the AAC barrel being nitrated it was averaging 50-75fps faster than my custom barrel I have on my other 260 and that got me thinking again... So a couple weeks ago I decided to start fresh and do a proper OCW starting at 41.5g of H4350 this time while using 139g Lapua scenars and rather than use the reformed 7mm-08 brass I decided to go with Lapua brass that has a thicker neck. The thicker neck (.002”) should improve overall group size by keeping the loaded round in the chamber closer to perfect alignment with the bore. After shooting the OCW at 100y round robin I saw a clear and wide node forming from 41.9 to 42.3 grains. I loaded up a few more at 42 and 42.2 and moved out to 300y where both shot well with 42 shooting just a bit tighter overall than 42.2, my velocity at 42 is 2790 and 42.2 is 2812 over 5 shots each clocked with a magnetospeed. This also proved to be true when I plotted my drops on JBM with the current weather conditions for 700 and 1000y. The plan is to split the node down the middle at 42.1 which should put me right at 2800 and test seating depth next. Until then I am happy to say for the third time in a row now I am seeing 5 shot groups staying at to just under .5 moa at 100 and at 700 I am seeing this.

I screwed up my hold at 1000 but after taking into account where I aimed verses where I hit, the rifle looks to be capable of shooting under .2 mil there as well... just not me, yet.

Earlier this year I came across a deal I could not pass up while window shopping on midway. They were selling off their inventory of AAC 260 barrels at half off. These barrels are pre threaded on both ends and chambered. The idea is to allow DIY’ers the ability to swap barrels on their Remington actions provided you have the proper tools. I place an order for a couple 260’s and a 308. This thread is about my time with the 260.

At first I thought I’d use one of my Remington’s that doesn’t get much use, a 26” 308 varmint. After searching this wonderful site for tips on how people have been taking off their factory barrels and gaining a little knowledge of the process (I will detail this in a later thread on the 18” 308 AAC barrel). I found the task straight forward and made the swap. However, after some productive range time that showed the barrel to shoot well I started thinking... dangerous I know...

I contacted Bugholes here on the hide and placed an order for one Stiller Tac30 A/W action. After just a few days I had my action...

I am happy to say it was a quick and easy swap and with the Stiller action and recoil lug everything fit nicely. I dropped in my go gauge and the bolt closed, dropped in my no go gauge and the bolt closed with heavy resistance, dropped in the field gauge and it would not even come close to closing... Just about perfect and tighter headspace than my three factory Remington rifles in the safe.

At first I attached the barreled action into a AICS stock and checked to see if my new action would feed from AW mags and I am happy to say it did.

first rounds on target

with a AAC 308 brake

Some dont care for the barrel profile but its grows on you and balances well

Then I tried AICS mags and found that the bolt was coming into heavy contact with the feed lips. So keep this in mind if you decided to take up a similar self build idea. If you use a AW action you may have to stick with AW mags. That said I have now swaped the barreled action into a Manners T4 and at this point it is feeding reliably with both unless you press into a barricade and/or hold pressure against the front of an AW mag. So there may be a happy medium where both mags will work or maybe not... I have not played around with making adjustments to the mag release that dictates the height of the mag when seated. That will have to wait till after deer season.

The barrel was giving me fits finding a load that would shoot well. Part of my problem was I have another 260 and assumed that a good accuracy node would/should work in both rifles... well it both does and doesn’t, it just depends on what you are after. The load I having been using in my other 260 (44g of H4350 w/140 class bullets) was way too hot to use in this barrel. Initially I found 43g of H4350 to work but it would shoot well one day and not the so well the next accuracy wise. My vertical was averaging .6 moa and then the next time out it would be near moa or larger at distances of 100-700 yards.

One thing I have noticed is with the AAC barrel being nitrated it was averaging 50-75fps faster than my custom barrel I have on my other 260 and that got me thinking again... So a couple weeks ago I decided to start fresh and do a proper OCW starting at 41.5g of H4350 this time while using 139g Lapua scenars and rather than use the reformed 7mm-08 brass I decided to go with Lapua brass that has a thicker neck. The thicker neck (.002”) should improve overall group size by keeping the loaded round in the chamber closer to perfect alignment with the bore. After shooting the OCW at 100y round robin I saw a clear and wide node forming from 41.9 to 42.3 grains. I loaded up a few more at 42 and 42.2 and moved out to 300y where both shot well with 42 shooting just a bit tighter overall than 42.2, my velocity at 42 is 2790 and 42.2 is 2812 over 5 shots each clocked with a magnetospeed. This also proved to be true when I plotted my drops on JBM with the current weather conditions for 700 and 1000y. The plan is to split the node down the middle at 42.1 which should put me right at 2800 and test seating depth next. Until then I am happy to say for the third time in a row now I am seeing 5 shot groups staying at to just under .5 moa at 100 and at 700 I am seeing this.

I screwed up my hold at 1000 but after taking into account where I aimed verses where I hit, the rifle looks to be capable of shooting under .2 mil there as well... just not me, yet.

Last edited: