I've been tossing around the idea of designing and building my own suppressor for some time now. I know about Form 1 and all the headaches that come with filling it out and getting it approved as well.

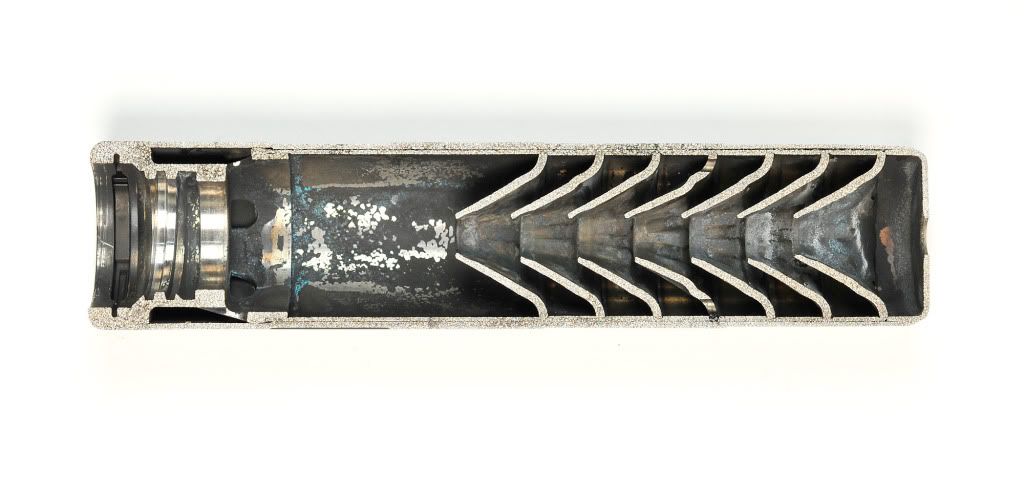

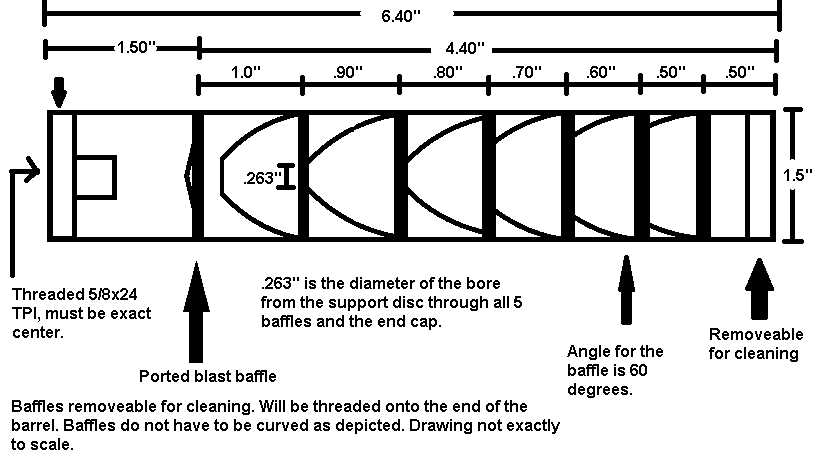

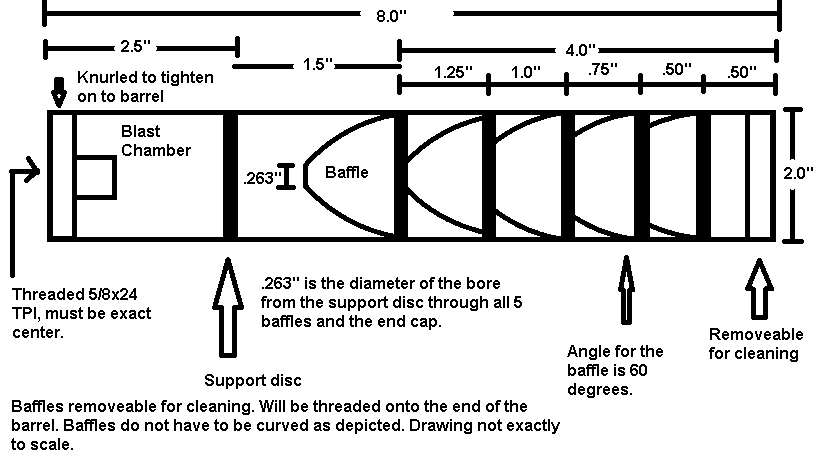

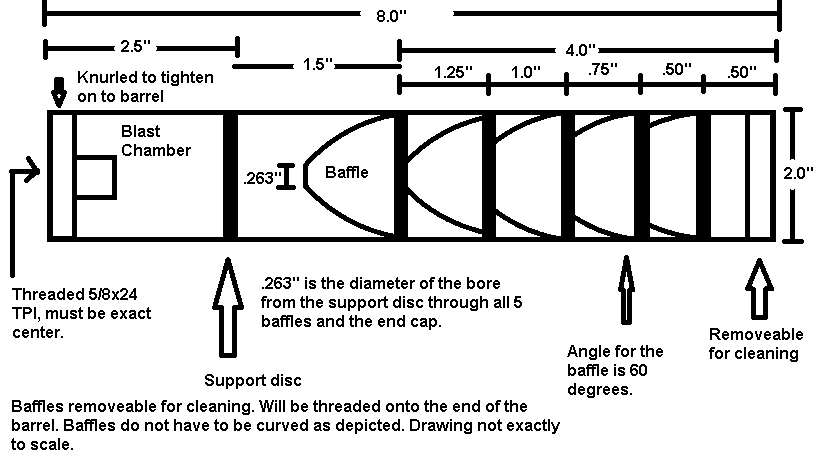

I'm going to set it up as a thread on. I'm not dead set on the length and diameter either after checking the dimensions on commercially available suppressors. Definitely considering going with a curved baffle design with ported spacer to try and break the gas up as much as possible. This will be going on my Adams Arms upper in 5.56 NATO, main goal is to make it hearing safe then toy around with different baffle designs to reduce the noise further.

Any and all input would help, it is my first foray into design much less implementing a suppressor (with the exception of an oil filter on a .22LR).

I'm going to set it up as a thread on. I'm not dead set on the length and diameter either after checking the dimensions on commercially available suppressors. Definitely considering going with a curved baffle design with ported spacer to try and break the gas up as much as possible. This will be going on my Adams Arms upper in 5.56 NATO, main goal is to make it hearing safe then toy around with different baffle designs to reduce the noise further.

Any and all input would help, it is my first foray into design much less implementing a suppressor (with the exception of an oil filter on a .22LR).